Silicon photonics technology has drawn significant interest due to its potential for compact and high-performance photonic integrated circuits. The Ge- or III–V material-based avalanche photodiodes integrated on silicon photonics provide ideal high sensitivity optical receivers for telecommunication wavelengths. Herein, the last advances of monolithic and heterogeneous avalanche photodiodes on silicon are reviewed, including different device structures and semiconductor systems.

To achieve efficient absorption at attractive near-infrared wavelengths, such as 1310 and 1550 nm, different semiconductor materials with narrower bandgaps have been integrated on Si. The integration of CMOS-compatible semiconductors, e.g., Ge, on a SiPh platform can easily leverage the mature CMOS technologies and provide high-performance photonic devices with low manufacturing costs. There is also no fundamental roadblock to prevent CMOS-incompatible materials, e.g., III–V, integrated on the large-scale Si wafers from being processed in a dedicated 200 or 300 mm process line to benefit process accuracy and throughput in CMOS production lines because of Intel’s huge success to commercialize III–V-on-Si diode lasers in their 300 mm production lines. Several integration methods have been developed to achieve high quality semiconductors on Si, including monolithic and heterogenous integrations. In this section, we introduce several typical material systems for SiPh-integrated APDs, namely Si–Ge, III–V, and QD APDs.

Similar to Si, Ge is a group-IV crystalline semiconductor. It is a widely used complementary material for Si in both electronics and photonics circuits that can be directly grown on Si. For light detection, Ge is an excellent material as its ~ 0.8 eV bandgap is narrow enough for efficient absorption in telecommunication wavelength windows, and the fast mobility of electrons and holes provides potential for high speed. Although the 4.2% lattice mismatch between Ge and Si causes misfits and threading dislocations, the improved growth techniques can reduce the dark current of Si–Ge APDs to an acceptable level. In the past ten years, with the development of SiPh, monolithic Si–Ge APDs have attracted extensive research interest. Si itself is a decent material candidate for the APD multiplication region because of its extremely low ratio of the impact ionization coefficients for holes and electrons, k, being only about 0.01–0.02 versus ~ 0.9 for Ge and ~ 0.4 for InP. For bulk multiplication regions, the excess noise factor is a function of the average gain and multiplication layer k value, which is given by F(M) = kM + (1− k)(2 − 1/M).

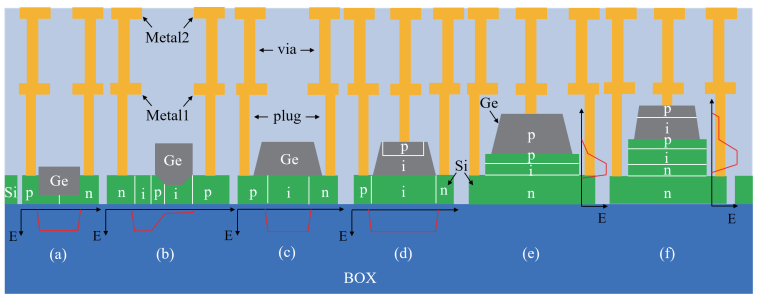

The excess noise factor increases with increasing gain M, while increases slower with lower k value. A low k means that electrons are much easier to get impact ionization than holes, reducing the stochastic gain fluctuations, thus the source of the excess noise is suppressed. In addition, Emmons has shown that low k value is also helpful for high gain-bandwidth product (GBP) in Ref. . Consequently, a multiplication region with low k value is desired in APD. Due to similar electron and hole ionization coefficients for Ge, its k value is close to unity (~ 0.9). Therefore, utilizing Ge as the absorption region and Si as the multiplication region can achieve advantages of both materials. Many device structures have been proposed for monolithic Si–Ge APDs, as shown in Fig. 1, from left to right, including lateral, hybrid vertical and lateral, and vertical structures.

Fig1

In addition to concentrating the electric field to form the multiplication region inside low k value Si, the thickness of the multiplication region is also important. A thin multiplication region can reduce the carrier transit time, which is the premise of achieving high bandwidth. Besides that, the deadspace effect cannot be ignored. Unlike the excess noise local model of Eq. (2), a non-local model is necessary because the carrier history should be included for the thin multiplication region. The effective k value will be further reduced with the dead-space effect. In the Hewlett Packard Enterprise (HPE), we demonstrated the Si–Ge waveguide SACM APDs with a p–p–i–n structure, as shown in Figs. 3(a) and 3(b), a 100 nm-thick intrinsic Si is used as the multiplication region and the E-field is confined inside it . This thin Si multiplication layer enables a high bandwidth and GBP because of the small transit time and build-up time. At 30 °C, the 4 × 10 μm2 Si–Ge waveguide APD exhibits a 3-dB bandwidth of ~ 26 GHz and a GBP of ~ 282.4 GHz as shown in Fig. 3(c) . And the inset I–V curve shows the Si–Ge APD has a low breakdown voltage of ~ –10 V with a highest gain ~ 20. All the measurements for the Si–Ge SACM APD are based on a 1550 nm laser. Another benefit of the thin multiplication region is its great thermal stability. The thin multiplication region requires a higher E-field to achieve the same gain than the thick one, such that carriers obtain sufficient ionization energy more quickly, and it results in less phonon scattering before avalanche breakdown. Therefore, carriers are less sensitive to temperature-dependent phonon energy. Figs. 3(d)–3(f) illustrate the temperature-dependent characteristics of gain, bandwidth, and eye diagrams, respectively . The 100 nm multiplication region Si–Ge SACM APD exhibits an excellent temperature stability as the breakdown voltage only increases ~ 4.2 mV/°C, bandwidth only reduces ~ 22 MHz/°C, and clear eye diagrams with 32 Gb/s NRZ and 64 Gb/s PAM4 are obvious at both 30 and 90 °C.

These APDs have shown the lowest dark current for any photodiode on silicon, as low as 10 pA (1 × 10−6 A/cm2 ) at –1 V for a 11 × 30 μm2 waveguide APD. Furthermore, the dark current density for a 11 × 60 μm2 device was 2.7 × 10–6 A/cm2 at –1 V and 3.4 × 10–6 A/cm2 at –1 V for a 11 × 90 μm2 device. The dark current scaling linearly with area suggests that the main contribution to the dark current comes from the bulk layers of the device. The low dark current is due to the combination of the 3-D carrier confinement of the QDs, good surface passivation of the PDs, low dislocation density and the high crystal quality of the active device material. Keeping the dark current low helps reduce the noise of the APD. The dark current was also measured as a function of temperature, as seen in Fig. 8(a). The breakdown voltage increases with temperature, implying that impact ionization is the main carrier mechanism behind the device breakdown.