Thermocompression bonding joins substrates via a bonding layer. In this paper, silicon substrates were bonded using gold thin films. Experimental data on the effects of bonding pressure (30 to 120 MPa), temperature (260 and 300 C), and time (2 to 90 min) on the bond toughness, measured using the four-point bend technique, are presented. In general, higher temperature and pressure lead to higher toughness bonds. Considerable variation in toughness was observed across specimens. Possible causes of the nonuniform bond quality were explored using finite element analysis. Simulation results showed that the mask layout contributed to the pressure nonuniformity applied across the wafer. Finally, some process guidelines for successful wafer-level bonding using gold thin films are presented.

WAFER bonding has enhanced fabrication capabilities for microelectromechanical systems (MEMS). While Si fusion and anodic bonding may be the most prominent wafer bonding methods, they are not the only options for joining substrates. Wafers can be effectively bonded together by using bonding layers such as polymers, solders and thin film metals. The incorporation of metals, especially those that are conductive, in conjunction with through-wafer via technology, also presents opportunities for packaging applications. Hybrid structures consisting of devices fabricated separately on different substrates can also be created by wafer-level bonding.

Metallic bonds form when the distances between the two substrates are so small that it becomes energetically favorable for surfaces to coalesce in order to eliminate the interfacial energy. The surfaces can be brought together by the application of pressure. Due to surface roughness, bonds initially form where the surfaces touch at asperity contacts. As the materials deform under pressure, the asperity heights decrease, and more areas are brought into contact. At room temperature, relatively high pressures are needed for interatomic attraction to overcome surface asperities in metals. But dislocation mobility and diffusion increases with temperature, resulting in softening of the metal and viscoplastic deformation. Therefore, the pressure requirement can be offset by increasing the processing temperature. The technique of simultaneous application of pressure and temperature during the bonding process is known as thermocompression bonding. This process is essentially identical to diffusion bonding, which is used extensively for joining metallic components at the macro scale.

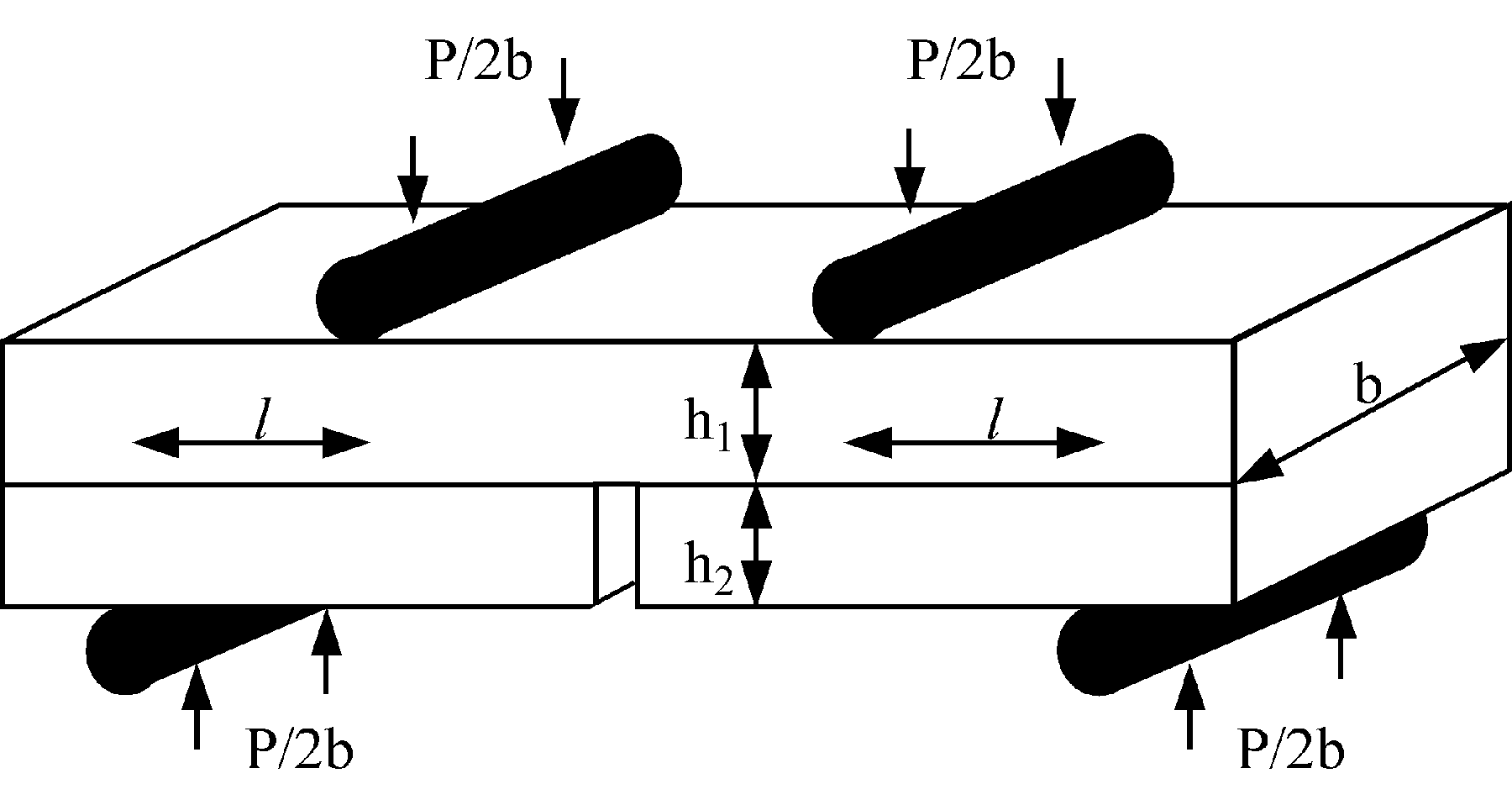

Fig1

In the wafer bonding literature, the bond integrity is often measured using the crack-opening method. The test creates a crack in the bonded wafer by insertion of a razor blade at the edge of the interface. The crack length, which is measurable in the infrared (IR), is then used to calculate the surface energy. Its simple implementation makes it a very attractive test technique. However, the crack opening is difficult to induce when the bond toughness is high, which often makes quantitative measurements impossible. Moreover, the technique is inapplicable when the bonding interface is opaque in the IR, such as gold.

Once the test was completed, a width-wise line was scribed on the surface of the DSP wafer, on either side of the KOH-etched notch and above the end of each of the cracks. The specimen was then loaded in a three-point bend jig to promote crack growth from the scribed line to the bond interface, thereby detaching the delaminated segments from the still bonded portion of the specimen. Since minimal force was required for this procedure, any observable deformation reflected those sustained during the four-point bend delamination test. The fracture surfaces were examined using a scanning electron microscope (SEM), optical microscope, and atomic force microscope (AFM).

上一篇: 接触纳米精密供体器件的全光刻工艺