This The SiC is a polar semiconductor that is easy to adsorb particles due to the surface charges, which results inthat the RCA process commonly used for silicon cleaning is not good for SiC cleaning, and the technique should be optimized.To check the surface charge of SiC wafers during the cleaning process, this work investigated the adsorption of polystyrenespheres (PS) on SiC epitaxial wafers at different pH values and measured the Zeta potential of the SiC wafers. We analyzed themechanisms by which the Zeta potential in alkaline (SC1) and acidic (SC2) cleaning solutions affects the adsorption of particleson SiC epitaxial wafers surface. The results showed that both the SiC epitaxial wafers and the particles had a negative Zetapotential in the SC1 cleaning solution and there was an electrostatic repulsion between them. In contrast, in the SC2 cleaningsolution, the SiC epitaxial wafers and particles had opposite Zeta potentials, which caused attraction between the wafers andparticles. Therefore, based on the analysis of Zeta potential, we proposed an optimized the SiC cleaning process that use SC2cleaning before SC1 cleaning. We successfully reduced the number of particles attached to the surface of SiC epitaxial wafersby 80.4% than RCA cleaning process by the optimized cleaning process. The optimized cleaning process would have a practicalvalue due to the reduction on the consumption of time and chemical reagents.

Silicon Carbide (SiC) is an exemplary wide bandgapsemiconductor material that possesses excellentcharacteristics such as high breakdown voltage, highsaturation electron drift velocity, high thermal conductivity,and high thermal stability[1]. It is an ideal material formanufacturing high-power electronic devices. As a polarsemiconductor, SiC is prone to adsorption of contaminatingparticles due to its charged surface[2]. These particles maycause problems such as circuit interruption or short-circuitingin subsequent device manufacturing[3], which can furtheraffect the manufacturing yield and stability of the devices[4].Therefore, developing effective cleaning processes is crucialin SiC semiconductor manufacturing[5].

Domestic and foreign scholars have conducted extensiveresearch on the cleaning process of SiC materials for a longtime. Based on the cleaning environment, it can be dividedinto dry cleaning and wet cleaning. Among these, the researchon dry cleaning processes mainly includes the following:Guan et al[6]. proposed a two-step method that involvedH2:He (1:1) plasma treatment and heating at a temperaturebelow 1000℃ to obtain a clean C-terminated SiC surface.Huang et al[7]. proposed an electron cyclotron resonancehydrogen plasma cleaning method, which can achieve anatomically flat and clean unreconstructed surface after 5minutes of treatment at a low temperature (200-700℃).Losurdo et al[8]. found that a clean SiC surface can beobtained by treating SiC material with atomic hydrogen at200℃.

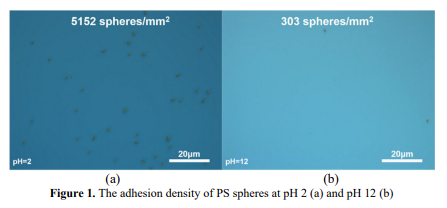

Fig1

SiC is a polar semiconductor that is primarily used in theindustry for epitaxial growth and device manufacturing on Sisurfaces[12]. As a result, this paper focuses on the charge stateof the Si surface of SiC wafers. Figure 1 illustrates theadsorption of PS spheres on the Si surface of SiC epitaxialwafers in solutions with pH values of 2 and 12, respectively.In Figure 1(a), where the solution pH is 2, the Si surface ofthe epitaxial wafer adsorbs a large number of PS spheres, witha statistically calculated surface adsorption density of 5152spheres/mm2. However, in Figure 1(b), where the solution pHis 12, the Si surface only adsorbs a small amount of PSspheres, with a statistically calculated surface adsorptiondensity of only 303 spheres/mm2. The significant differencein the PS sphere adsorption density on the SiC surface inFigure 1 demonstrates that the solution pH value is thedetermining factor that affects the amount of PS sphereadsorption.

上一篇: 使用 TMAH 溶液垂直蚀刻氮化铝铝薄膜