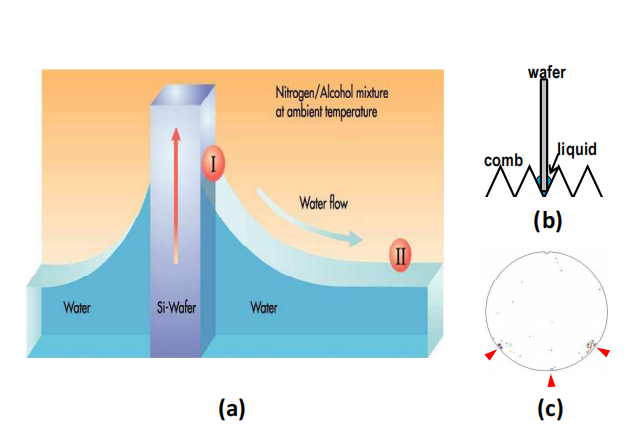

Contact mark contamination of Si wafers in Marangoni drying is related to water retention at the contact area between wafers and a process holder. The formation of water retention at wafer/holder contact is addressed with a conceptual model. A technical approach of capillary drainage is proposed to tackle the contact mark issue, along with experimental verification.

·Diffusion of IPA vapor into water through the gas/liquid interface

·IPA concentration at the meniscus geometry (Spot I) is greater than at the bulk surface(Spot II)

· Since IPA decreases surface tension, liquid surface tension at Spot I is lower than atSpot II

·Marangoni force from the surface tension gradient pulls liquid from Spot I to Spot II

·Slow withdrawal of the wafer out of water results in a dry and clean wafer surface

While the Marangoni process is effective in drying wafer surface well and clean, it has encountered a challenge at the contact area between the wafer and wafer-holder. To prevent the wafers from touching each other in wet processing and to facilitate the automation of wafer transfer in a wet bench, a wafer holder normally has saw-tooth like design to keep individual wafers in relatively fixed position. If the surface tension gradient generated by Marangoni effect does not fully overcome the capillary force existing at the tight geometry of the wafer/holder contact area, liquid can remain at this area and dries by evaporation, resulting in contact mark contamination issues, as shown by figure 1b and 1c. Since the inception of Marangoni drying, there is little discussion of wafer contact mark issues in the literature. NAURA Akrion has developed a Marangoni type of wafer dryers, LuCID™, to integrate with its GAMA™ wet station product line. In this paper, a new approach is proposed to tackle the contact mark problem and discussed along with experimental results.

上一篇: 光刻胶的选择标准