Abstract

The authors have developed a new process as an alternative to sulfuric peroxide mixture (SPM) cleaning of Si wafers.This process, vapor ozone strip (VOS), uses ozone and vaporizecwater, significantly reducing any effect on environment, health andsafety The process is more effective than ozone water immersion.because high concentration ozone gas and high temperature watercan be used simultaneously. Also, the process uses the highly reactive OH* radical species. The VOS process is able to strip pho.toresist at a higher rate than other techniques using ozone. lon implanted photoresist and etched photoresist can be stripped. VOShas demonstrated equivalent performance to SPM in electrical re.liability testing.

I.INTRODUCTION

HE RCA cleaning method introduced by W Kern in 1970ill remains most popular. In recent years, improvementshave been made in chemical purity and ratios have been refinedTable I shows the chemistries most commonly used.As a more environmentally benign alternative to the RCAclean, functional water has recently been investigated. In particular, use of ozone and water for removal of organic contamina-tion has been ofinterest (3]-5]. However, atypical ozone watergenerator can make only about 10-30 ppm of ozone in water atroom temperature and atmospheric pressure. Under such condi.tions the photoresist removal rate is limited to only 100 nm/min.which is insufficient as an alternative to sulfuric peroxide mix-ture (SPM). Our goal was to achieve a higher photoresist removal rate using ozone and water. In this paper, we report ouldevelopment approach, the technique developed, and its com-parison with SPM.

II.VAPOR OZONE STRIP

A. Development Approach

The case of conventional ozone ashing is instructive. Theozone asher decomposes ozone into oxygen and oxygen radicals (O*) at an elevated temperature by reactions (a) and (b).

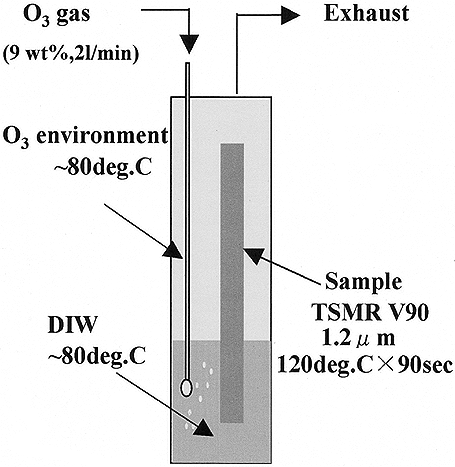

Reaction (a) is promoted by introduction ofheat or UV light [6]By reaction (b) ofO* with carbon, photoresist can subsequentlybe removed. High temperature increases the rate of photoresistashing, and 325 °C has been shown to have an excellent resulf[7]. Reaction (b) particularly requires heat, and we concludedthat high temperature is important for achieving high efficiencyof organic removal by ozone and water as well. Accordinglywe conducted the experiment shown in Fig. 1(a). A photoresist (1.2-um thickness) coated piece of silicon wafer was soaked indeionized water (DIW), heated to 80 °C in a beaker. To make ahigh concentration of ozone in the hot water, 9 wt% ozone gaswas injected in the hot water.

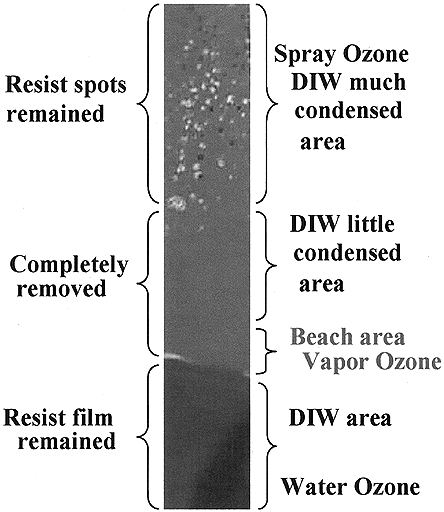

Figure1 a、b

Photoresist removal ability was observed to separate intothree distinct regions after the 5-min process as shown inFig. 1(b). Whereas the top and bottom of the sample showedlittle photoresist removal, the middle portion showed a highremoval rate. In the middle portion a mixture ofhigh concentration ozone gas and hot water vapor contacts the wafer surfaceBased on this experiment, the idea of VOS was developed, andwe focused on creating a stable mixture of water vapor andhigh concentration ozone that would cover the entire wafer andprovide the most efficient organic removal. Fig. 2 shows theresulting VOS concept. Some key points are as follows.

上一篇: 砷化镓功率异质结双极晶体管

下一篇: 光伏应用的砷化镓径向结构