The influences of a megasonic wave on water and bubblemotions in a wet cleaning bath used for 300 mm-diameter siliconwafers were studied. The water motion in the entire bath wasobserved using a tracer of water-soluble blue-colored ink. Themegasonic wave accelerated the water motion in the entire bath.although the water motion under no megasonic wave tended to belocalized. The motion of small bubbles generated by the megasonicwave was also traced over the entire wafer surface. The bubbletransport rate was shown to be increased by the megasonic waveand water flow.

Introduction

The silicon wafer surface is cleaned following wet processes using ultrapure watervarious chemical reagents, and very often megasonic wave (1-10), Additionallymicrobubbles generated by the megasonic wave have been used for various cleaningtechniques (11,12). Thus, the method and conditions for its effective use have beenstudied by many researchers (6, 9, 10, 13, 14) based on the particle level evaluation ofcleaned silicon wafer surface. In order to further improve the wet cleaning conditions in awet cleaning bath, the motions of the water and bubbles under the megasonic waveshould be sufficiently clarified. Although the water flow under a megasonic wave hasbeen studied by numerical calculation in the notable previous papers (15-20)experimental study using the visualization technique should be further performed.

In this paper, the motions of the water and bubbles in an entire carrierless wetcleaning bath were studied under megasonic wave at various powers. Based on theobtained results, the role and influence of the megasonic wave are discussed.

Experimental

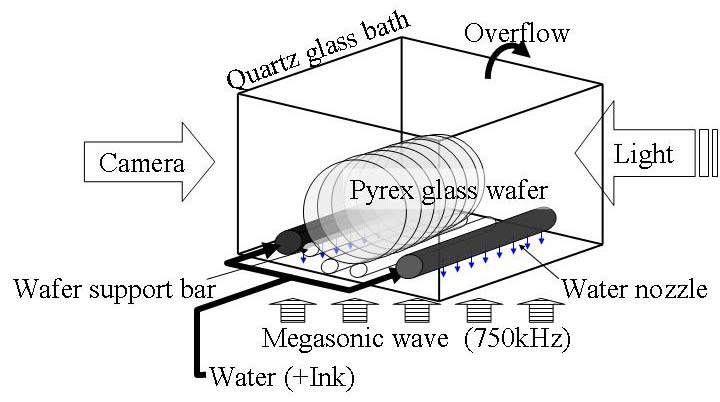

Figure 1 shows a schematic of the carrierless wet cleaning bath used in this studyThis system consists of a bath, 25 wafers (300 mm-diameter), three wafer support bars.and two water nozzles. The bath and the water nozzles are made of quartz glass. Thewafer support bars are made of a fluorocarbon resin. Most of the wafers used in this studywere made of transparent Pyrex glass, which was employed in order to easily observe the tracer motions between the wafers. The distance between the wafers was set at 10 mm when 25 wafers were placed in the bath.

Figure 1

Water exits the water nozzles, then the water overflows from the top of the bath Thewater flow rate was 15 L min'. The temperature of the water was room temperature, andwas sufficiently exposed to air. A 750 kHz megasonic wave was added from the bottomof the bath at a power of 0-1300W. At this frequency, many small bubbles are producedbut cavitation is very weak (21).

In this study, in order to visualize the water motion, a water-soluble blue-colored inkwas added to the water. The motion of blue-colored ink was captured every 60-90 s usinga VTR camera. The motion of the small bubbles in the bath was illuminated using a sheetof light produced using a LCD projector connected to a personal computer: it wascaptured using the Super Eye C2847 and DVS-3000 system (Hamamatsu Photonics Co.I td., Japan).

Results and Discussion

Water motion

Fig. 2 shows the water flow in the wet cleaning bath, which contained 7, 13 and 25wafers with a distance of 30, 15 and 10 mm, respectively, between the neighboringwafers. The water flow rate was 15 L/min. The arrow at the left bottom of eachphotograph shows the direction of the water stream going into the water nozzle. Eachphotograph was captured 2 s after the injection of the blue-colored ink into the bath fromthe small holes in the water nozzle.

上一篇: 氮化铝陶瓷的金属化