Abstract

In this work, titanium dioxide (TiOz) thinfilms have been deposited on glass and monocrystallinesilicon by Atmospheric Pressure Chemical Vapor(APCVD) techniquetitaniumDepositionusingtetrachloride TiCl4 as precursor. The structural, electricaland optical properties of the prepared TiO2 thin filmswere evaluated by Atomic Force Microscopy (AFM)Four Point Probe (FPP) and Spectroscopic Ellipsometry(SE), respectively. These properties were exploited forapplication of the TiO layers as antireflection coatingson monocrystalline silicon solar cells. Our experimentalresults show that the deposited TiO, thin films werepolycrystalline, homogenous, compact and relativelysmooth. The measured average optical transmittance ofthe TiO, films was about 85-90%. From the ellipsometryanalysis, the refractive index of our TiO, thin films wasfound to be n-225 at the wavelength 入= 550 nm, with athickness of 56,2 nm. These experimental resultsobtained by APCVD are in excellent agreement with thecomputed results of the TiO, refractive index and thickness required for a high quality antireflectioncoating in industrial conditions. The obtained resultsdemonstrate the real opportunity of the APCVDtechnique to prepare high quality antireflection coatingsfor crystalline solar cells. This indicates that the APCVDantireflection coatings mayhave a high potentialindustrial application.

1. Introduction

Titanium dioxide (TiO) in thin films form hasseveral properties that make it a material of interestfor lots of applications. Indeed, TiO, films can beused as coating in anticorrosive protection, ascatalysts in chemical industry and environmentalpurificationphenomena.TiO, thin filmshaveexcellent electrical and optical properties, such as ahigh refractive index [l], [2] andexcellenttransmittance in the visible and near IR region ofthe solar spectrum [3], [4]. Since TiO, is highlytransparent, it acts like a window for thetransmission of solar radiations. Due to itsinteresting optical properties, these films have beenwidely used as antireflection coatings (ARC).

High quality antireflection coatings are required forthe realization of high performance solar cells. Oneof the optical requirements for antireflectioncoating is high refractive index. This characteristiccan be achieved by optimization of the filmpreparation technique. Several techniques havebeen developed for elaborating the TiO, thin films[5],[6], [7], [8]. Among them, atmospheric pressurechemical vapor deposition or APCVD is one of themost attractive, as it is known to be a low costgiving high density stoichiometric andprocessuniform films [9]. Moreover, it is especially applicable to large area, continuous deposition, asrequired for growth on glass or crystalline silicon[9]. Due to its several advantages, CVD has becomeone of the main processing methods for thedeposition of amorphous, monocrystalline andpolycrystalline thin films and coatings for a widerange of applications.

In this work, TiO, thin films were fabricated onglass and monocrystalline silicon substrates byAPCVD from the reaction of titanium tetrachlorideTiCl4 with oxygen. The structural, electrical andoptical properties of the prepared TiO2 thin filmswere evaluated by Atomic Force Microscopy(AFM), Four-point probe (FPP) and Spectroscopicellipsometry (SE), respectively. In the light of theseresults, thesepropertiesexploited forwereapplication of the TiO, layers as single-layerantire flection coatings (SLARC) monocrystalline silicon solar cells.

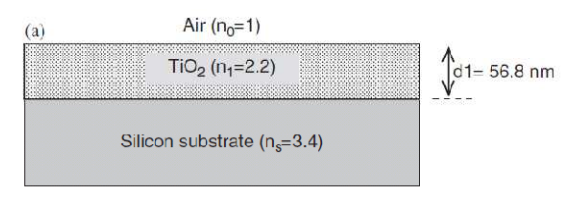

According to [10], achieving low reflectance formonocrystalline silicon solar cells having TiO2 asantireflection coating, is possible when therefractive index of the TiO, layer is equal to n-22at 入 550 nm with an estimated thickness of 56.8nm as illustrated in figure 1. These values can beachieved experimentally by optimization of the filmpreparation conditions.

Figure1. Design diagram of a TiO2 single-layer antireflection coating [10].

2. Experimental details

A. Preparation ofTiO, thin films

In this work, we have deposited the titaniumdioxide thin films on glass and monocrystallinesilicon using the APCVD technique. The titaniumtetrachloride TiCl4 (liquid) was used as the mainprecursor to form the titanium dioxide films.