Abstract. The ultra-high heat flflux cooling characteristics and impingement behavior of cryogenic micro-solid nitrogen (SN2) particles in relation to a heated wafer substrate were investigated for application to next generation semiconductor wafer cleaning technology. The fundamental characteristics of cooling heat transfer and photoresist removal-cleaning performance using micro-solid nitrogen particulate spray impinging on a heated substrate were numerically investigated and experimentally measured by a new type of integrated computational-experimental technique. This study contributes not only advanced cryogenic cooling technology for high thermal emission devices, but also to the fifield of nano device engineering including the semiconductor wafer cleaning technology.

In recent years, thermal-flfluid mechanical high functionality of cryogenic fifine solid particles of micron size has been noted in the fifield of ultra-high heat flflux cooling technology in application to high thermal emission devices [1]. In order to make effective use of the high performance of such cryogenic solid particles in the fifield of advanced nano technology, our laboratory has developed a new physical semiconductor cleaning method which employs cryogenic spray .

Especially, with progress in the use of a high aspect ratio and a fifine cantilever in semiconductor nano structures, development of a cleaning method in which no water is used is strongly desired [4]. Because of the capillary force due to the surface tension of water that remains in the structure in the process of drying, the fifine structure is deformed by capillary force, fifinally causing collapse or adhesion. Accordingly, in ultra-fifine processing, it is quite diffificult to use pure water because of its large surface tension. Thus, the application of a fifine solid nitrogen spray for physical semiconductor cleaning methods without the use of water would be very useful. Therefore, the application of cryogenic high-speed spray of micro-solid nitrogen (SN2) [5] to resist-removal and a semiconductor wafer ultra-cleaning system is the focus of great interest.

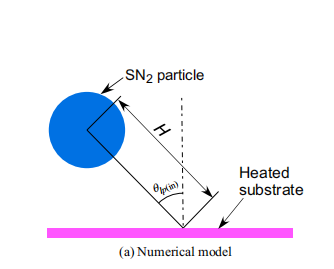

Fig1

When the SN2 particle impinges on the substrate, qw increases and the substrate is suddenly cooled down. It was numerically found that the ultimate high-heat flflux cooling was attained by micro-SN2 spray impingement. The satisfactory effect of decreasing temperature was obtained in the substrate surface region where the contact area of impinging SN2 particle on the substrate became large. This effective cooling performance is mainly caused by the wall contact heat transfer of SN2 particle impingement and cryogenic forced convection due to the SN2 inertia force. The most advantageous factor of the SN2 spray cooling system is the utilization of the direct contact heat transfer SN2 particles and latent heat transport with phase change which avoids the fifilm boiling state. Also, ultra-short time scale heat transfer in a thin boundary layer is more possible than in LN2 spray . When micro-SN2 particulate flflow was used, as an ultra-high cooling heat flflux level was achieved during operation, a better cooling performance was obtained than that with liquid nitrogen (LN2) spray cooling .

For the wafer samples employed in the present experiment, stripping performance in the case of positive KrF photoresist-coated poly-crystalline silicon/gate silicon oxide/silicon substrate was examined. These wafers were manufactured as follows. Firstly, an 8-inch p-type silicon substrate was thermally oxidized and a 6-nm-thick gate silicon oxide layer was deposited on the substrate. LPCVD (low pressure chemical vapor deposition) was employed to deposit a 150-nm- thick layer of poly-crystalline silicon on the gate oxide. An HMDS (Hexamethldisilazane) layer was applied to the surface of the poly-Si to assist in adhesion of photoresist to the poly-Si, and then a photoresist layer 500 nm in thickness was formed over the HMDS layer with the use of a spin coater. The photoresist was patterned using KrF eximer light at 193 nm. The gate length was 0.34 μm and the gate width was 10 μm.