In the current study, monocrystalline silicon nanowire arrays (SiNWs) were prepared through a metal-assisted chemical etching method of silicon wafers in an etching solution composed of HF and H2O2. Photoelectric properties of the monocrystalline SiNWs are improved greatly with the formation of the nanostructure on the silicon wafers. By controlling the hydrogen peroxide concentration in the etching solution, SiNWs with different morphologies and surface characteristics are obtained. A reasonable mechanism of the etching process was proposed. Photocatalytic experiment shows that SiNWs prepared by 20% H2O2 etching solution exhibit the best activity in the decomposition of the target organic pollutant, Rhodamine B (RhB), under Xe arc lamp irradiation for its appropriate Si nanowire density with the effect of Si content and contact area of photocatalyst and RhB optimized.

Silicon materials, which exhibit a wide optical adsorption range, high optical absorption efficiency, and high electron mobility, become a great potential photoelectric conversion material for its important applications in the field of photovoltaics and photocatalysis . The realization of the silicon structure, especially the preparation of nanowire arrays, is very significant for the development and production of efficient quantum devices, photoelectric devices, and electronic and optical sensors . Various methods have been developed to prepare one-dimensional silicon nanostructures, such as chemical vapor deposition , supercritical fluidliquid–solid synthesis , laser ablation, thermal evaporation decomposition , and other processes.

In recent years, a simple catalytic etching technique with metal particles as catalyst to prepare large-area aligned monocrystalline silicon nanowire arrays on silicon wafers has been reported . The technique is actually a wet chemical corrosion, the process of which is relatively simple, low cost, and controllable. Recent works on the etching method with depositions of two-dimensional (2-D) micro/nanoparticle arrays or 2-D nanopattern fabrications with highly ordered configurations, which are applicable for enabling highly dense nanowire formation, have also been reported. The controlled depositions of micro/nanoparticles result in close-packed highly ordered 2-D arrays with monolayer configuration, and these methods had been implemented in photonic devices. In addition, the use of diblock copolymer lithography methods had enabled the fabrication of highly ordered and ultrahigh-density 2-D nanopattern arrays. However, literatures about the influence of etching solution composition on the morphologies and properties of Si nanowire arrays are rarely reported.

In this paper, we use monocrystalline silicon wafers as the matrix, Ag as the catalyst, and hydrofluoric acid (HF) and hydrogen peroxide (H2O2) as the etching solution to prepare silicon nanowire arrays utilizing the wet chemical etching method. The photoelectric properties of the monocrystalline silicon nanowire arrays and the silicon wafers were also investigated. Additionally, in our study, we found that the increase of H2O2 concentration can influence the morphology and surface characteristics of the nanowires, which may affect their light absorption and photocatalytic properties.

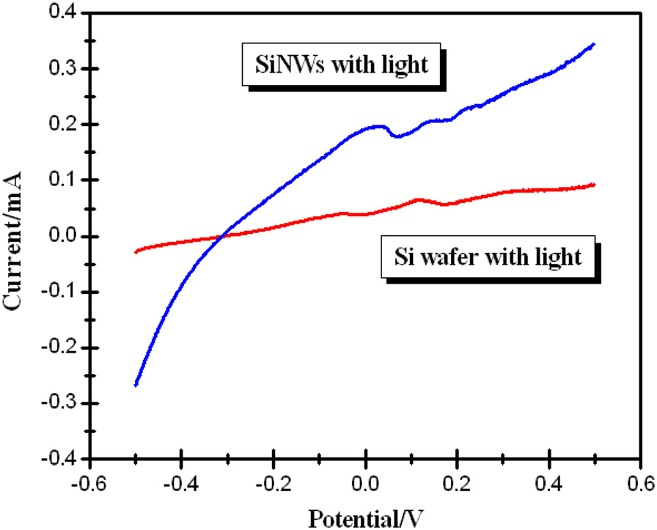

Fig4

Figure 4 shows the photoelectrochemical results of the silicon wafer and 10% SiNWs. From the photoelectrochemical results of the silicon wafer and 10% SiNWs, we can obviously draw the conclusion that in the illumination condition, the light current of the 10% SiNWs is higher than that of the silicon wafer (10% SiNWs, 0.35 mA; Si, 0.09 mA; with an applied voltage of 0.5 V). The improved light current may be ascribed to the enhanced adsorption ability and photogenerated carrier separation efficiency of the 10% SiNWs, taking advantage of the formation of the Si nanowire structure. Therefore, it can be clearly inferred that the construction of the nanostructure is an effective way to improve the photoelectric performance of silicon materials.

上一篇: Si多层膜的选择性化学湿法蚀刻