Quantum dot light-emitting diodes (QLEDs) are usually a flflat multilayer structure. The luminous effiffifficiency of QLEDs is limited because the light extraction is constrained owing to the substrate mode at the air/substrate interface, the waveguide mode at the conductive glass/organic interface, and the surface plasmon polaritons (SPPs) along the metal/organic interface. To improve the light extraction for the luminous effiffifficiency of QLEDs, light transmission through the QLEDs coupled with three difffferent surface micro-nanostructures is simulated by using a ray-tracing method. Furthermore, QLEDs (red, green, and blue emission) coupled with micro-nanostructures are also fabricated to investigate the inflfluence of the micro-nanostructures on the luminous effiffifficiency. Our simulation results show that more light escapes from the QLEDs coupled with surface micro-nanostructures than the control devices without micro-nanostructures. Our experimental results are consistent with the simulation results. By coupling with surface micro-nanostructures, the luminous effiffifficiencies of the devices exhibited great improvement, and the EQE of R/G/B trichromatic reached 17.3%, 2.81%, and 10%, respectively, which are about 1~2 times higher than those of the control devices without any surface structure. Our results should make a contribution to building a strategy for improving the luminous effiffifficiency of QLEDs.

Herein, we introduced three micro-nanostructures upon the light exit surface of QLEDs with a multilayer structure and carried out both simulation and experimental investigations on their inflfluences on the luminous effiffifficiency of the devices. For simulation investigation, the ray-tracing method was used to analyse the light transmission through the QLEDs with/without micro-nanostructures. The simulation results indicated that the microlens array is benefificial for the light extraction of QLEDs. Furthermore, for experimental studies, QLEDs with a typical structure (ITO/PEDOT:PS-S/poly-TPD (TFB)/QDs/ZnO/Al) based on CdSe/CdS/ZnS (red), CdSe/ZnS/ZnS (green), and CdZnS/ZnS (blue) QDs were fabricated. By integrating micro-nanostructures with the light exit surface, all the fabricated devices exhibited higher EQE than the control devices without micronanostructures. By coupling with a flflat convex, the luminous effiffifficiencies of the devices exhibited great improvement, and the EQE of R/G/B trichromatic reached 17.3%, 2.81%, and 10%, respectively. These values were about 1~2 times higher than those of the control devices. Besides, when the light exit surface was coupled with a flflat convex lens whose bottom is fifilled with a compound eye structure, the output lights show a more uniform angle distribution, despite the fact that the improvement of EQE was not as high as that obtained by using a simple flflat convex lens. Our simulation and experimental results confifirm that further EQE improvement should be possible through integrating the light exit surface with a surface micro-nanostructure.

The ray-tracing method was used to demonstrate the effffect of micro-nanostructures on the luminescence of QLEDs. The models for simulation are illustrated in Figure 1. The schematics for QLEDs coupled with a microprism array (Model I), a flflat convex lens (Model II), and a flflat convex lens whose bottom is fifilled with a compound eye structure (Model III) are given in Figures 1(a)–1(c), respectively. For comparison, a control model without any micro-nanostructure (Model IV) shown in Figure 1(d) is also investigated.

Fig1

The simulation results are shown in Figures 2(a)–2(d), corresponding to the models in Figures 1(a)–1(d), respectively. It can be seen from Figure 2 that surface micronanostructures can reduce the internal total reflflection and enhance the luminous effiffifficiency obviously. It is calculated that the number of rays emitted outside from the QLED without an external coupling surface structure is only 1509, and the total luminous flflux is 0.044141W. For Model I using the microprism array as the light exit surface, its simulation results are a little higher than those of the control model and with better light distribution. While for Models II and III, the number of rays emitted outside from QLEDs is 3304 and 2709, respectively, and the output luminous flflux is 0.10593 and 0.094645, respectively. These results exhibit distinguishable improvement compared to those of Models IV and I. The simulation results for all four models are summarized in Table 2.

For the fabrication of QLEDs, PEDOT:PSS, poly-TPD, QDs, and ZnO were spin coated on the ITO glass substrate in turn in the glove box fifilled with inertia gas. The thickness of these fifilms was controlled by adjusting the solution concentration and the rotating speed. Finally, aluminium is deposited on the surface of the ZnO layer by using a vacuum evaporation method. Finally, the slide glass is packaged on the chip by UV-curing adhesive, and the fabrication of QLED is completed.

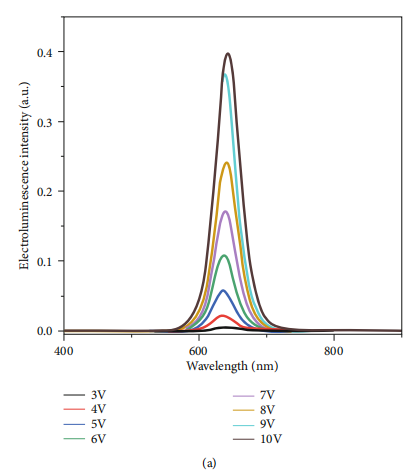

To obtain high-effiffifficiency QLEDs, the rotating speed, the rotating time, and the solution concentration were optimized. Moreover, poly-TPD was used as the hole transport layer for the red-emission device and poly-TFB for the green and the blue ones. The electroluminescent (EL) spectra of the fabricated QLEDs of difffferent emission colours without surface modifification are shown in Figure 3. It can be seen from Figure 3 that the emission peaks of the devices are 645 nm, 525 nm, and 460 nm, respectively. However, with the increase of applied voltage, the EL spectra shift to the longer wavelength slightly, which may be caused by the Stark effffect. This phenomenon of spectral shift is similar to that of QLEDs based on CdSe/CdS/ZnS, CdSe/ZnS/ZnS, and CdZnS/ZnS QDs reported previously.