Quantum dot light-emitting diode (QLED) attracted much attention for the next generation of display due to its advantages in high color saturation, tunable color emission, and high stability. Compared with traditional LED display, QLED display has advantages in flexible and robust application, which makes wearable and stretchable display possible in the future. In addition, QLED display is a self-emissive display, in which light is generated by individual subpixel, each subpixel can be individually controlled. Each subpixel in LED display is constituted by liquid crystal and color filter, which make LED display have lower power efficiency and less enhanced functionality. This chapter introduces the QLED based on the QLED structure and light-emitting mechanism of QLED. Then, a novel method for fabricating QLEDs, which is based on the ZnO nanoparticles (NPs) incorporated into QD nanoparticles, will be introduced. The QLED device was fabricated by all-solution processes, which make the QLED fabrication process more flexible and more suitable for industrialization. What is more, as QLED devices were planned to integrate into a display, all-solution fabrication processes also make printing QLED display device possible in the near future.

The organic materials had an advantage of high luminescence, while inorganic materials had an advantage of high reliability. Then the researcher combined the advantage of both organic materials and inorganic materials by using both organic materials and inorganic materials as the electron transport layers. MoS2, NiO, TiO2, and ZnO have been reported as the inorganic charge transport layers (CTLs).

Among these four types of QLED structure, inorganic materials are one of the most important choices for electron transport layers owing to their high electrical conductivity and good stability against environmental factors such as oxygen and moisture. ZnO nanoparticles (NPs) applied in electron transport layer are a significant breakthrough in QLED development history, due to their excellent electron mobility and no significant damage to the underlying QD layer during fabrication process. What’s more, ZnO NPs are compatible with both polar solvent and nonpolar solvent, which makes the QLED fabrication process more flexible. More details about ZnO NPs will be introduced in Section 3.

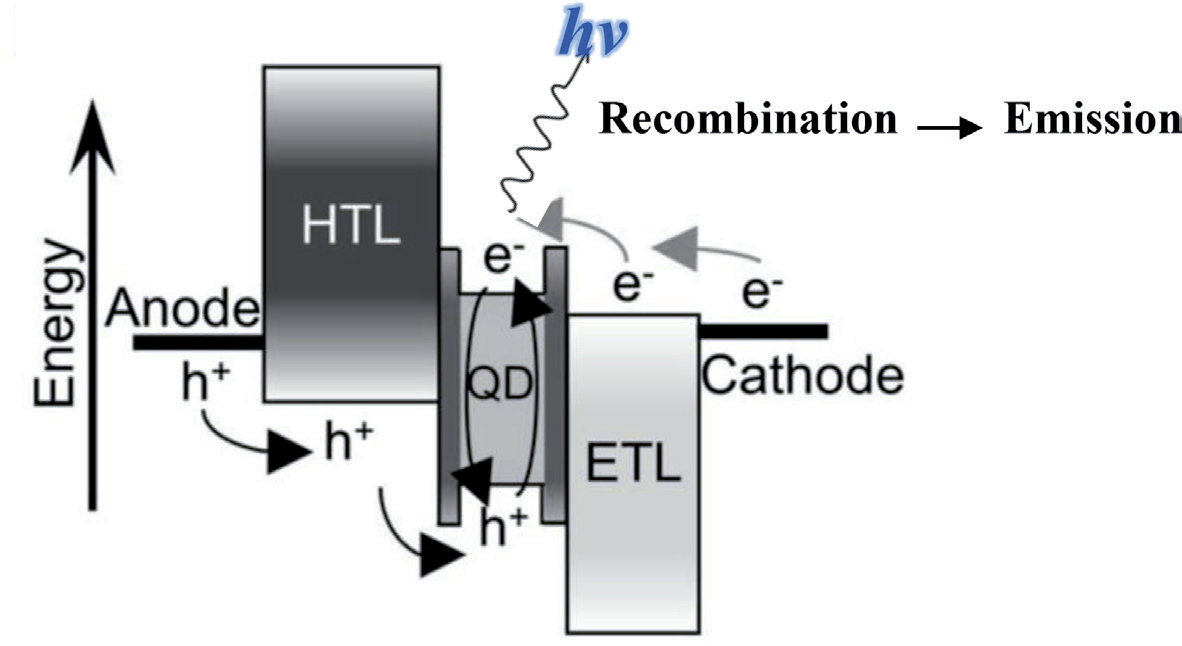

The emission mechanism of QLED is discussed in this subsection. A QLED has a similar structure and behavior as an OLED. In the QLED, the emitter is a semiconductor nanoparticle, while in the OLED, the emitter is an organic material.

Once a molecular orbital achieved the maximum electron energy, it is called the highest occupied molecular orbital (HOMO). Otherwise, if a molecular orbital has unfilled electrons, the molecular orbital is called the lowest unoccupied molecular orbital (LUMO). The energies of HOMO and LUMO affect the ionization potential and electron affinity of materials (Figure 3).

Before considering the light emission mechanism, it is important to understand the electron configuration in both the ground state and the excited state. Before excitation, when in ground state, the electrons are placed with both upward spin and downward spin (Figure 3). When excited, the electrons in the upper state are allocated with the same spin state, or the spin is reversed. The light emission is resulting from the energy transfer from the excitation state to the ground state.

Fig1

Generally, solution-processed oxide CTLs can be deposited by two approaches, the precursor approach and the nanocrystal approach. The molar ratio of zinc precursor to potassium hydroxide (KOH) played an important role in determining the shape of ZnO NPs and hence affected the conductivity and mobility of ZnO NP film prepared from ZnO NPs. ZnO NPs were synthesized by hydrolysis/ condensation reactions under basic conditions. The synthesis procedure will be introduced in Section 3.

Detergent TFD4 was purchased from BioLab, PEDOT:PSS 4083 from Heraeus, poly-TPD (LT-N149) from Luminescence Technology Corp Ltd., patterned ITO glass from Xinyan Technology Ltd., green (CdZnSeS/ZnS) quantum dots from Suzhou Mesolight Inc., and zinc acetate dihydrate powder, potassium hydroxide flakes, acetone, isopropyl alcohol, methyl alcohol, chloroform, and chlorobenzene all from Aldrich.

下一篇: 量子点显示技术及与OLED显示技术的比较