The QLED that we are making now, in addition to the evaporation of the a layer, the other layers are generally obtained by solution spin-coating. In our experiments, the selection strategies for quantum dots and adjacent layers of solvents were summarized. Based on these strategies, we selected the appropriate solvent to obtain high quality films, and in order to avoid the quantum dot film laye being corroded, and the surface having streaky defects, thereby hindering the high performance of the device. This solvent selection strategy provides a common method for preparing high quality films for most solution processed multilayer optoelectronic device.

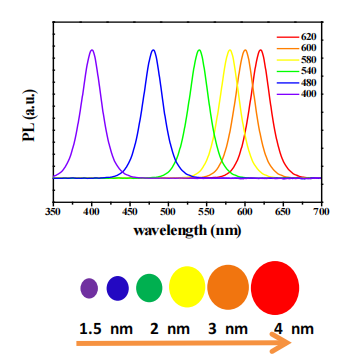

QDs are microparticles of several tens of nanometers synthesized by chemical solution growth. Quantum dots have many characteristics, such as it can change its size to get different emission spectra. As shown in Figure 1 below. It has not only a very narrow emission spectrum and a wide excitation spectrum, but also has good light stability and a large Stokes shift. Apart from these, it’s fluorescence lifetime is long, so it is now the ideal luminescent material for QLED. Quantum dot LEDs are comparable to the best oleds available today, because they have a wider color gamut than traditional LEDs , the emission peak is narrower and the color is more saturated.

A quantum dot light-emitting diode emits light by excitons radiating a composite photon in a quantum dot. There are two main ways to form excitons: first, carriers are directly injected into the quantum dots from the transport layer to form excitons; second, excitons are formed in the hole transport layer, and then excitons in the hole transport layer pass, energy is transferred to the quantum dots to form excitons and radiate complex luminescence. The injection rate of carriers in a quantum dot directly affects the rate of formation of excitons in a quantum dot. If the film quality of each functional layer is good, it helps the injection of carriers and the formation of excitons in quantum dots, which can increase the recombination of excitons and improve the efficiency of the device.

Now the functional layer of QLED is generally formed by solution spin coating. Its structure is shown in Figure 2. It is more efficient and less expensive than inkjet printing technology. The full solution of QLED faces a huge challenge. If the solvent is not properly selected, the underlying function will be corroded by the solvent when the next layer is spin coated. Therefore, we need to obtain a smooth, pinhole-free quantum dot film to avoid serious short-circuit and non-radiative recombination of QLED. Therefore, the morphology of quantum dot films is one of the keys to determining the performance of quantum dot light-emitting diodes. We need to obtain a smooth underlying charge transport layer to improve the efficiency of QLED devices.

In QLEDs treated with full solution, the use of orthogonal solvent dissolution between adjacent layers is the most common strategy. The quantum dot light-emitting layer has a thickness of only several tens of nanometers and is easily destroyed by the solvent of the adjacent layer. This phenomenon is avoided if the solvents are orthogonal. Quantum dots are generally dissolved in toluene, but once spin-coated on the Tpd (solvent is chlorobenzene) hole transport layer, the hole transport layer will be destroyed by the destruction of toluene. We tested the 380nm thick Tpd layer after annealing and its optical density Od decreased from 0. 35 to 0. 05 after cleaning with toluene.

Fig1

A quantum dot light-emitting diode emits light by excitons radiating a composite photon in a quantum dot. There are two main ways to form excitons: first, carriers are directly injected into the quantum dots from the transport layer to form excitons; second, excitons are formed in the hole transport layer, and then excitons in the hole transport layer pass, energy is transferred to the quantum dots to form excitons and radiate complex luminescence. The injection rate of carriers in a quantum dot directly affects the rate of formation of excitons in a quantum dot. If the film quality of each functional layer is good, it helps the injection of carriers and the formation of excitons in quantum dots, which can increase the recombination of excitons and improve the efficiency of the device.

Now the functional layer of QLED is generally formed by solution spin coating. Its structure is shown in Figure 2. It is more efficient and less expensive than inkjet printing technology. The full solution of QLED faces a huge challenge. If the solvent is not properly selected, the underlying function will be corroded by the solvent when the next layer is spin coated. Therefore, we need to obtain a smooth, pinhole-free quantum dot film to avoid serious short-circuit and non-radiative recombination of QLED. Therefore, the morphology of quantum dot films is one of the keys to determining the performance of quantum dot light-emitting diodes. We need to obtain a smooth underlying charge transport layer to improve the efficiency of QLED devices.

In QLEDs treated with full solution, the use of orthogonal solvent dissolution between adjacent layers is the most common strategy. The quantum dot light-emitting layer has a thickness of only several tens of nanometers and is easily destroyed by the solvent of the adjacent layer. This phenomenon is avoided if the solvents are orthogonal. Quantum dots are generally dissolved in toluene, but once spin-coated on the Tpd (solvent is chlorobenzene) hole transport layer, the hole transport layer will be destroyed by the destruction of toluene. We tested the 380nm thick Tpd layer after annealing and its optical density Od decreased from 0. 35 to 0. 05 after cleaning with toluene.

上一篇: 量子点显示技术及与OLED显示技术的比较