The energy produced by solar photovoltaic (SPV) modules is directly connected with the solar accessible irradiance, spectral content, different variables like environmental and climatic components. Dust and bird droppings are considered as the real challenges for SPV performance. This article covers dust-related challenges and advanced improvements made on the automated cleaning system, by providing a brief framework on strategies such as mechanical, electrical, chemical and electrostatic. The environmental impact of cleaning processes has also been evaluated, which is directly related to the ultimate performance of overall conversion.

Utilization and conversion of solar energy is a complex photochemical process, requiring optimization of several parameters for an acceptable level of efficiency, where the process is directly controlled by surface characteristics and its cleaning. Solar photovoltaic (SPV) cleaning and prevention from dust are two main aspects of maintenance required for enhanced and longer yield. Other parameters such as increase in temperature, overheating and physical hindrance of sunlight may cause its scattering from the SPV surface resulting in low absorption.

Although cleaning of solar panel has been a defining challenge for researchers mainly for balancing the cost with performance and durability, continuous efforts in this direction seem to be a positive step towards enhancing the efficiency of the devices. Dust is a fine, dry powder comprising miniature units of earth or waste material6 . Dust settlement for the most part depends on numerous components like compound properties, size, weight, shape, site, tilt point surface completion, stickiness, wind speed, etc.7–11. Dust exposure affects many parameters of SPV; so several attempts have been made to address this issue (Tables 1 and 2). However, there are a variety of approaches for cleaning depending on weather or on power generation capacity (Tables 3 and 4).

There are several challenges and benefits related to the cleaning techniques. All the techniques are mainly focused on reducing the adhesion bond between dust particles and the panel by controlling electrostatic repulsion (ER)12–18. This strategy is aimed at incorporating materials or system designs that use non-contact, continuous techniques which require little or no labour for cleaning.

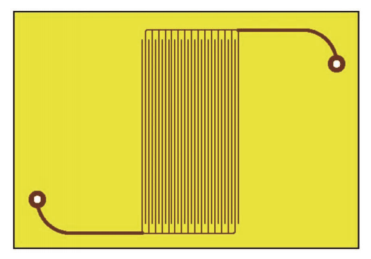

This is mainly directed at SPV cleaning in space application. Apart from the traditional/conventional cleaning techniques, special ones are required for space related conditions. The process should be non-contact type, which reduces manpower. As the space environment (explored so far) is dry or non-humid, and since the dust particles are ionized due to lack of atmosphere around them, suitable techniques were applied earlier. An electrostatic biasing film consists of rows of transparent, conducting, parallel electrodes sandwiched between two transparent dielectric layers. This film is integrated with SPV module on its optical surface to maintain high transmission efficiency without the need for water. To remove dust particles deposited on an electrostatic biasing film surface, the electrodes are activated by applying low-frequency, high-voltage pulses. The dust particles are then electrostatically charged and removed by Coulomb force. Electric field distribution and dust particles charge acquired during removal play an important role during the cleaning process and evaluation of electrostatic performance.

Fig1

Multiphase electric curtain: Similar to the standing wave, to generate travelling nature of the wave at a direction normal to the electrode axes, three-phase supply including phase shifts of 2π/3 and 4π/3 has been provided to electrodes (non-uniform electric field distribution). Two types of force components act over the charged particles, which include an outward component along Oz (normal to the plain of the curtain) and a component along Ox (parallel to the plain of the curtain and normal to the axis of the electrodes). The resulting force (called dielectrophoretic (DEP) force) is relative to the particle charge, field, field gradient and frequency and help for lift to the charged particle to sweep of the field (Figure 2). Above mentioned technique of multiphase electric curtain is been used by Masuda et al.24 developed a layer of electric curtain which prevents the charged particles from reaching the SPV surface, and further lifting and transporting the charged particles.

Solar panel cleaning robot is a two-body structure for SPV module cleaning. It comprises a mobile robot which carries the cleaning payload and cleaning head, which actually does the cleaning work. The cleaning head undergoes horizontal motion with the help of motorized trolleys at the edges of panels, while the belt-driven system attached directly with the cleaning head undergoes vertical motion. Cleaning head comprises rotating antiscratch cylindrical brushes to scrub the SPV surface and a scraper to remove the dirt solution (Figure 3).

Washing of SPV panels is traditionally known for effective cleaning using centralized cleaning facilities. For optimizing the performance, it is better to clean the panels early in the morning and using pressure-induced demineralized water. As the SPV surface is wet due to dew, it can be rinsed easily. Meanwhile, when SPV panel temperature becomes high (mid-noon), it requires more water and human effort to get the desired result.

上一篇: 集成 TOSA 和高速EML 芯片