This paper reports on a set of experiments to determine what efficiency gain can be achieved by using AR coated glass and to evaluate the weatherability of the coatings. AR coated glass from three different vendors was evaluated by building and testing full size modules. Only one of the three vendors’ glass produced consistent increases in STC efficiency on the order of 2.4 to 3%. All of the three types of coated glass successfully passed the accelerated stress tests from IEC 61215. Modules made with the glass that consistently produced STC efficiency gains were then deployed outdoors for extended time periods in order to measure the energy production. Preliminary results indicate that the energy production difference between the AR coated glass and the standard low iron glass is in excess of the gain measured at STC.

It is well known that use of an anti-reflective coating on the outer glass surface can increase the coupling of light into a PV module and therefore increase its conversion efficiency. While AR coated glass has been available for years, in the past these coatings were unable to survive long term exposure outdoors. Recent advances in glass coating technology have improved the ability of the coatings to survive the outdoor environment. AR coated glass was obtained from three different vendors.Each material was evaluated for encapsulation gain and subjected to accelerated environmental tests. One of the three materials produced consistent efficiency gains. This material was then subjected to more rigorous testing to define the expected performance under standard test conditions (1000 W/m2 , AM1.5 spectrum, 25° C) and to determine the expected energy gain from outdoor use of this material.

Flash test results taken under Standard Test Conditions (1000 W/m2 , AM1.5G spectrum, 25° C) for the modules made using the Vendor #1 AR coated glass are shown in Table 1. The screen print multicrystalline silicon data is from ten test modules and ten controls from the BP3160 family. The Laser Grooved Buried Contact (LGBC) mono-Si data is taken from six test modules and six controls from the BP7180 family. The screen print mono-Si data is taken from three test modules and is compared to production data on a large number of modules from the BP4175 family. This glass produced a significant increase in power (2.5 to 3%) driven by higher short circuit current (2 to 2.6%) as expected for AR coated glass.

Glass from the other two vendors did not result in measurable gains above our standard glass. In both cases their un-AR coated glass produced less power than our standard glass. So while their AR coated glass resulted in increased output over their non-AR coated glass, it did not provide an advantage over our standard glass.

Fig1

Since the AR coating improves the optical coupling of light into the module, it is the current that should be higher for the modules made with AR coated glass. Figure 3 is a plot of the normalized current, IDN as a function of time for 2 modules with AR coated glass and a control module under outdoor test in Homebush, Australia for more than a year. In all cases the AR coated modules produce 4 to 6% more current than the control module. These results indicate that the coatings were stable over the time frame of the test.

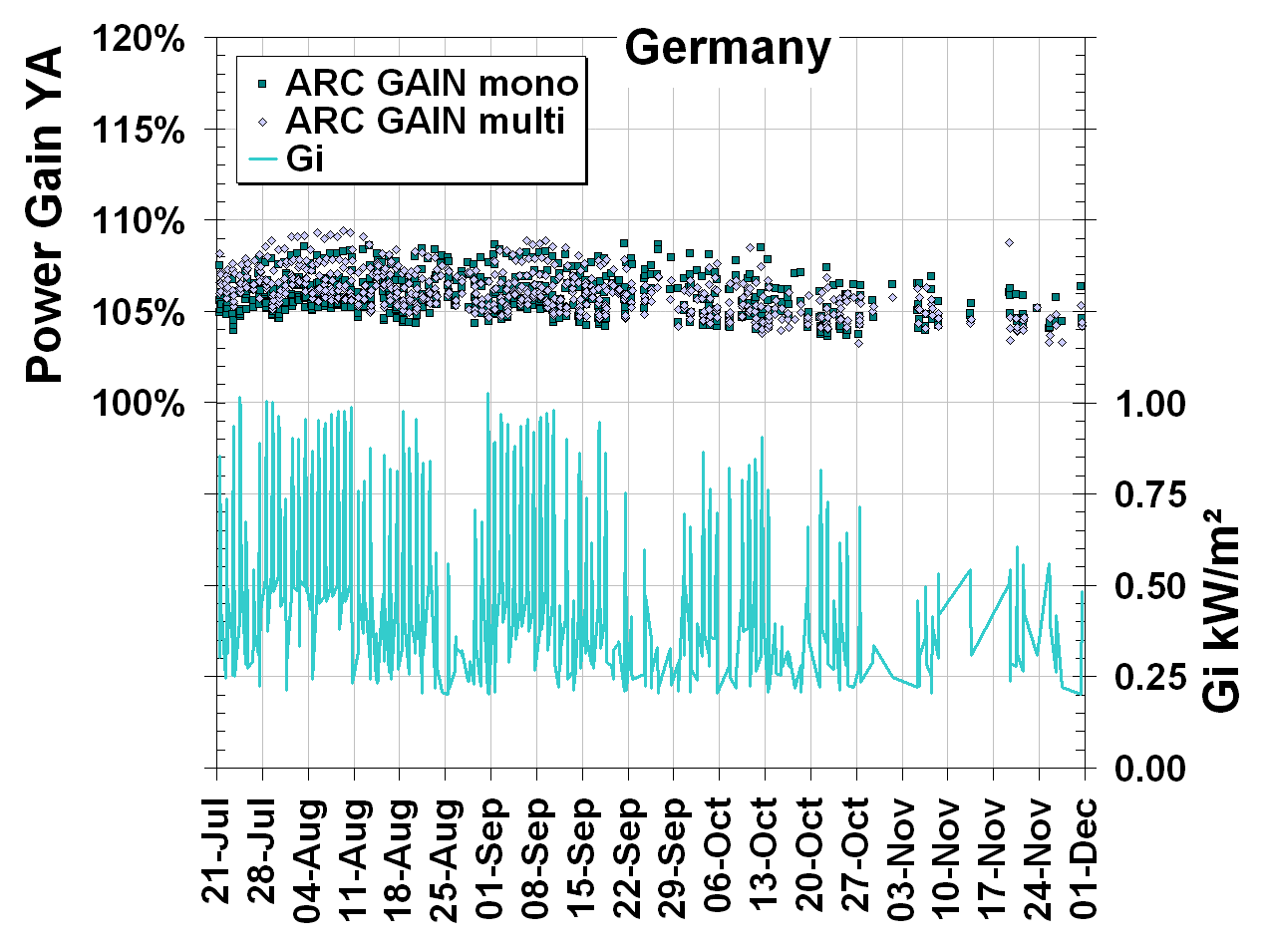

Analysis of the data from Australia and Germany indicates that in all cases the energy gain due to the AR coated glass is greater than the increase in STC power as measured in a simulator. The increase in energy is typically 4 to 6% (depending upon the time frame and location) versus the measured STC power gain of 2.5 to 3.0% that was shown in Table 1. However, because of the small sample size it is impossible from this data to predict with any accuracy how much additional energy will be produced when these modules are used under varying weather conditions around the world.

The pilot run included 231 AR coated glass modules and 231 control modules made with standard low iron glass. The modules were processed alternately (one AR and then one standard) in order to eliminate variability in the results.

下一篇: 基于MEMS的不同类型的谐振器