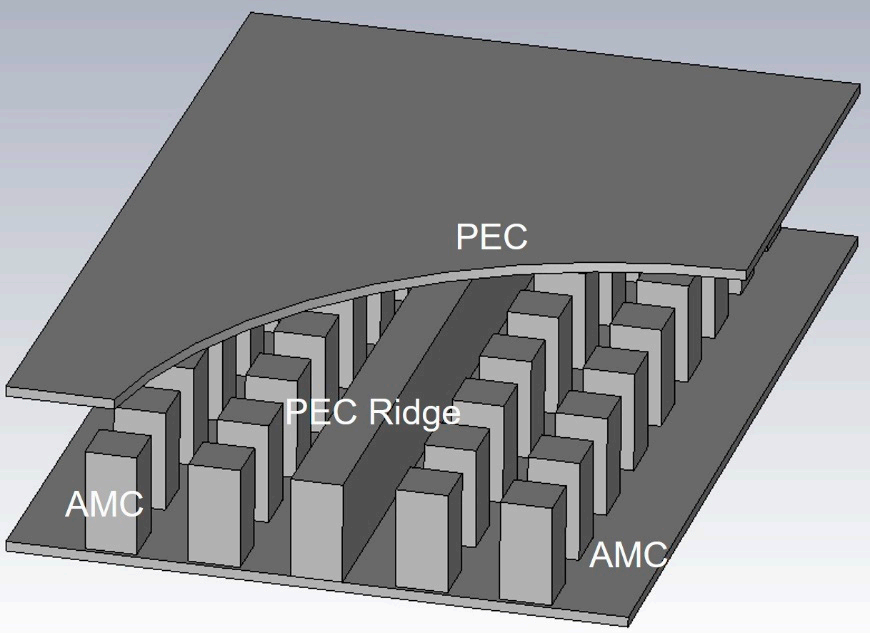

This paper presents a novel fabrication method based on dry fifilm photoresists to realize waveguides and waveguide-based passive components operating at the millimeter-wave frequency (30–300 GHz). We demonstrate that the proposed fabrication method has a high potential as an alternative to other microfabrication technologies, such as silicon-based and SU8-based micromachining for realizing millimeter-wave waveguide components. Along with the nearly identical transfer of geometrical structures, the dry fifilm photoresist offers other advantages such as fewer processing steps, lower production cost, and shorter prototyping time over the conventional micromachining technologies. To demonstrate the feasibility of the fabrication process, we use SUEX dry fifilm to fabricate a ridge gap waveguide resonator. The resonator is designed to exhibit two resonances at 234.6 and 284 GHz. The measured attenuation at 234 GHz is 0.032 dB/mm and at 283 GHz is 0.033 dB/mm for the fabricated prototype. A comparative study among different existing technologies indicates that the reported method can give a better unloaded Q-value than other conventional processes. The measured unloaded Q-values are in good agreement with the simulated unloaded Q-values. The signal attenuation indicates that SUEX dry fifilm photoresists can be used to fabricate passive devices operating at millimeter-wave frequencies. Moreover, this new fabrication method can offer fast and low-cost prototyping.

The millimeter-wave (mm-wave) frequency band has gained a lot of attention over the past few years due to growing commercial applications such as automotive radars, security, imaging, and point-to-point communication links . At the mm-wave frequency range, computer numerical control (CNC) milling is still the most common method to manufacture passive components such as waveguides, antennas, and fifilters. As the operating frequency approaches higher frequencies, the dimension of the waveguide and waveguide-based components continue to decrease. The decreasing feature size of these waveguide components makes the traditional fabrication method more and more challenging in terms of time and cost. A new fast and low-cost manufacturing process to cope with the strict manufacturing tolerances is needed. Micromachining due to the high dimensional accuracy and the possibility of achieving high-aspect-ratio structures has the potential for the manufacturing of mm-wave components. Among different micromachining techniques, silicon-based micromachining , SU8 photoresist-based process, and LIGA-based thick layer electroplating are suitable for manufacturing mm-wave components.

Dry fifilm photoresists are widely used in printed circuit board (PCB) technology and offer many advantages such as no edge bead, thickness uniformity over the whole wafer, fast processing, straight sidewalls, requiring fewer sophisticated tools, and overall lower fabrication cost. Dry fifilm photoresists have already been used to defifine microflfluidic channels, electroplate molds for LIGA processes , and for sealing of flfluidic channels . Among different dry fifilm photoresists, the epoxy-based dry fifilm photoresist SUEX also appears to be a promising material for a wide range of MEMS applications. However, dry fifilm photoresists have never been used for the fabrication of the waveguide components for radio frequency (RF) applications.

Fig1

A commercial laminator (PRO SERIESTM 3600) was used to laminate SUEX dry film sheets. SUEX dry film sheets were sandwiched between two polyester (PET) films. Figure 4 is the schematic of a dry film sheet covered with a PET sheet on each side. The PET sheet of one side was removed before laminating the photoresist against the substrate. The lamination of the resist was carried out at controlled temperature and pressure. The lamination temperature of the roller depended on the thickness of the dry fifilm sheet. The PET sheet that was kept during lamination needed to be removed before exposing the laminated layer or laminating another dry film sheet.

上一篇: 在负性光刻胶上制造悬浮微结构的方法

下一篇: 有机薄膜晶体管电路