During the last decade the dc and rf sputtering techniques have been used extensively in their two configurations — balanced and unbalanced magnetron. The main applications have been in the fields of industry and research. Examples of industrial applications are: decorative thin films (Raymond & Baham, 1999), hard wear-resistant thin films (Rodil & Olaya, 2006), low-friction thin films (Heimberg et al., 2001) corrosion-resistant thin films (Flores et al., 2006), and thin films used as a protective optical system (Stefan et al., 2008), as well as maybe the most interesting applications, thin films used in the electronic industry (Monroy et al., 2011). In the research field, the investigation has been oriented toward understanding the main physical mechanisms, such as: interaction between charged particles and the surface of the target material, adherence between the substrate and the deposited material, and chemical reactions near the substrate, as well as the influence of the deposit parameters (substrate temperature, working pressure, density power applied to the target). This research has produced thin films with a high degree of crystallinity and with the possibility of various industrial applications.

Moreover, researchers have made an effort to improve the system of operation. These efforts have been initiated through the so-called conventional or balanced magnetron sputtering in the early 1970s (Waits R, 1978), followed by the development of unbalanced systems in the late 1980s (Window, 1986) and its incorporation into multi-source “closed-field” systems in the early 1990s (Teer, 1989). Finally, the sputtering technique can increase the rate of deposition and ion energy by applying a unipolar high power pulse of low frequency and low duty cycle to the cathode target, referred to as high-power impulse magnetron sputtering (HiPIMS) or high-power pulsed magnetron sputtering (HPPMS). Common to all highly ionized techniques is very high density plasma. Implementing these discharges in sputter deposition technology modifies the surface of components, bringing improvements in mechanical, chemical, optical, electronic, and many other properties of the material. Highcurrent glows are transient discharges operating at simultaneously high voltage (> 300 V) and high current density (> 100mAcm−2). They have recently proven successful for the deposition of thin-film materials. These developments have made it possible to have an exceptionally versatile technique, suitable for the deposition of high-quality, well-adhered films of a wide range of materials with high rates of deposition. Table 1 show the main applications obtained in the last decade with the magnetron sputtering (balanced and unbalanced) rf and dc versions.

In dc (diode) discharge, the cathode electrode is the sputtering target and the substrate is placed on the anode, which is often at ground potential (Vossen &Cuomo, 1978). The applied potential appears across a region very near the cathode, and the plasma generation region is near the cathode surface. The cathode in dc discharge must be an electrical conductor, since an insulating surface will develop a surface charge that will prevent ion bombardment of the surface. This condition implies that dc sputtering must be used to sputter simple electrically conductive materials such as metals, although the process is rather slow and expensive compared to vacuum deposition. An advantage of dc sputtering is that the plasma can be established uniformly over a large area, so that a solid large-area vaporization source can be established.

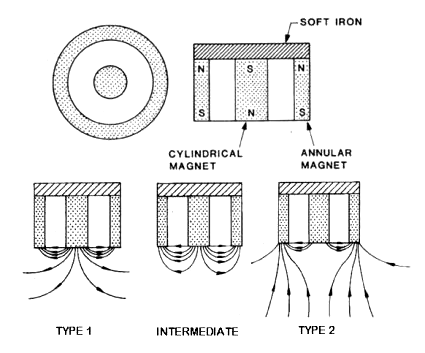

On the other hand, in dc sputtering the electrons that are ejected from the cathode are accelerated away from the cathode and are not efficiently used for sustaining the discharge. To avoid this effect, a magnetic field is added to the dc sputtering system that can deflect the electrons to near the target surface, and with appropriate arrangement of the magnets, the electrons can be made to circulate on a closed path on the target surface. This high current of electrons creates high-density plasma, from which ions can be extracted to sputter the target material, producing a magnetron sputter configuration (Penfold, 1995). A disadvantage of the magnetron sputtering configuration is that the plasma is confined near the cathode and is not available to active reactive gases in the plasma near the substrate for reactive sputter deposition. This difficulty can be overcome using an unbalanced magnetron configuration (see Fig. 1), where the magnetic field is such that some electrons can escape from the cathode region (Windows & Savvides, 1986). A disadvantage of the unbalanced magnetron is that the current of escaping electrons is not uniform, and the plasma generated is not uniform.

Fig1

It is important to state that in all the cases discussed above, the target and the substrate were facing (on- axis sputtering). In this configuration, the highly energetic electrons irradiate the substrates and/or the growing surface of the thin films during deposition. Off-axis sputtering reduces the effects of the irradiation of the high-energy particles. In off-axis sputtering, the substrates are settled at the outside of the discharge plasma. The thickness distribution of thin films deposited by off-axis sputtering will be larger than that for on-axis sputtering. A rotating substrate holder with a metal shadow mask is used for the reduction of the thickness distribution of the off-axis sputtering. Under a suitable design, the thickness distribution is less than 2% for substrates of 100 × 100 mm in an rf sputtering system using a 5-inch target.

In this chapter we will present the physical parameters involved in the growth of thin films; also discussed will be the influence that the growth parameters have on the degree crystallinity of the films, the chemical characterization, and the optical characterization of the films; and finally, we will discuss the residual stress, hardness, and corrosion and wear resistance of thin films.

The main physical phenomenon involved in the sputtering technique is the momentum transfer between energetic atomic-sized particles (usually ions of noble gases) and the atoms of the surface of the material (target). During the interchange of momentum, many effects can be produced on the elastic and inelastic collisions; in the first kind of collision, mainly reflected particles can be found (neutrals, ions of the target and the gas). In the second kind, the collisions can present secondary electrons, UV/visible photons, X-ray and implanted particles; schematically, Fig. 3 shows different processes that may occur during the interaction between charged particles and the surface of the material.

下一篇: 硅、锗和硅锗光电池在热光伏中的应用