Sputter deposition of metals in a capture medium with extremely low vapor pressure is a simple and convenient method to generate the metal nanoparticles (NPs) without chemical reactions. By careful selection of the capture medium and/or temperature of the medium for the deposition, the size of the synthesized NPs can be controlled. Sputtering conditions also play an important role in determining the size of NPs. We synthesized Au NPs in a standard ionic liquid, 1-butyl-3-methylimidazolium tetrafluoroborate ([C4mim]BF4) by systematically varying the sputtering conditions, which influence the formation processes and/or the size and size distributions of Au NPs. The Au NPs were characterized by small-angle X-ray scattering immediately after the synthesis of NPs in the capture medium. It is concluded that the temperature of the target and applied voltages have a strong influence on the size of Au NPs generated in the capture media, while the working distance between the target and the surface of the capture media, sputtering time, and discharge current have little or no influence. Lower temperature of the target and higher applied voltage are desired for generating size-controlled smaller NPs.

Contrary to the usual wet processes in which metal nanoparticles (NPs) are synthesized by chemical reactions in liquids, other physical vapor deposition processes have attracted much attention as unique methods to generate metal NPs. In these methods, atoms, clusters, or fragments of metals are ejected by sputtering,1 thermal evaporation,2,3 or laser ablation4,5 and are captured in a medium to form NPs. Except the laser ablation, the capture medium used for this purpose must have an extremely low vapor pressure to endure vacuum operation. Moreover, if the medium has the stabilizing ability to prevent NPs from aggregating, we can generate clean NPs in it with neither chemical reaction nor additional stabilizing agents. The combination of sputtering to generate atoms or small clusters and deposition in ionic liquids (ILs) as the capture medium is an elegant method from the viewpoint of operation simplicity and possibility to generate NPs with relatively uniform sizes. Vapor pressures of most ILs, if any,6,7 are negligibly small. When ILs are used as the capture media, complicated devices8-10 are not necessary and metal NPs are obtained through a very simple operation. The constituent ions of ILs stabilize the generated NPs; therefore, no additional stabilizing agents are needed. Since the first report on the sputter deposition technique using ILs as capture media for NP synthesis,11 many investigations1,12-18 have been performed to develop the preparative techniques and elucidate the formation mechanisms and factors determining the size and shape of NPs.

Other media apart from ILs have been used as the capture media in sputter deposition techniques. For environmental friendly and easier treatments after the generation of NPs, Dupont et al. succeeded in the preparation of Au NPs in castor oil,19 and we also successfully generated Au NPs in liquid polyethylene glycol with lower molecular weight.20 In both capture media, it is considered that oxygen atoms are coordinated to the surface of Au NPs and –CH2–CH2– chains worked as stabilizers by surrounding the NPs.

Fig1

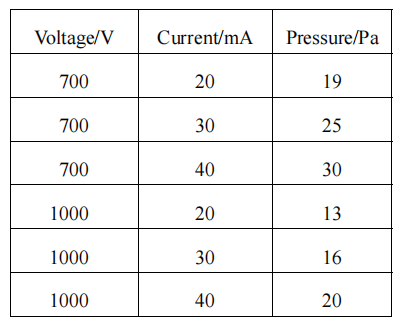

On the other hand, the influence of applied voltage significantly affects the size of the generated Au NPs. Smaller Au NPs with a wider size distribution are generated from the Au particles sputtered at high applied voltages. We cannot explain this applied-voltage effect, as discussed below. First, we focus on the effects from the viewpoint of the kinetic energies of ejected Au particles. The kinetic energies of sputtered neutral Au particles are of the order of 100 eV even at applied voltages of 43 kV.32 Moreover, no strong voltage dependence of the energy distribution was observed when the applied voltage varied from 80 to 1200 V for Cu particles sputtered by Kr+ . 33 Although no data on the energy distribution of sputtered Au particles by Ar+ at around 1000 V is found in the literature, from the above-mentioned experimental results, we may infer that the kinetic energy distributions of sputtered neutral Au particles do not vary with applied voltages of 700 or 1000 V. Therefore, we cannot obtain decisive explanation on the size dependence from the kinetic energies.

Second, let us discuss the applied-voltage effect from the viewpoint of clusters which are generated from the beginning by the Ar+ sputtering. Gerhard et al. reported that the ratios of Au2 and Au3 clusters to Au atoms in Ar+ sputtering at the applied voltage of 1000 V are 0.12 and 0.0016, respectively, and that the ratios of clusters increase with higher applied voltage.34 If larger NPs are generated from larger sputtered clusters, Au NPs generated at the voltage of 1000 V should be larger than those at 700 V. This, however, is contrary to our experimental observations.

From the kinetic energy and clustering of sputtered Au particles, we cannot explain the present experimental results regarding the dependence of size of NPs in the capture medium on applied voltage. However, larger Au NPs are certainly generated by a lower applied voltage. This is consistent with the recent report by Wender et al.,18 who generated Au NPs of size 3.6 ± 0.4 nm with applied voltage 335 V, discharge current 40 mA, and capture medium [C4mim]BF4.

上一篇: 红外研究二氧化硅和二氧化锗的多晶型

下一篇: 溅射法中的生长薄膜及其应用