The removal of particles from commercial silicon wafers by Steam Laser Cleaning was examined. Polystyrene colloids were used as model contaminants due to their well defined size and shape. In contrast to previous studies, where the experimental conditions on the surface were only roughly determined, special care was taken to control the amount of liquid applied to the surface. We report measurements of the cleaning threshold for different particle sizes. The comparability of the results was ensured by the reproducible conditions on the surface. Moreover, we studied the in- fluence of different liquid film thicknesses on the cleaning process. Investigations of laser induced liquid evaporation showed that the cleaning threshold coincides with the fluence necessary for the onset of explosive vaporization. After particle removal, the surface was examined with an atomic force microscope. These investigations demonstrated that near fifield enhancement may cause defects on the nm-scale, but also showed that Steam Laser Cleaning possesses the capability of achieving damage-free removal for a large range of different particle sizes.

In order to conduct systematic measurements of the laser fluence threshold for particle removal, polystyrene colloids were used as model contaminants. The major advantages compared to other particles are their spherical shape and narrow size distribution, which allow a comparison to models and the investigation of diameter dependent effects. The colloids were deposited on the precleaned samples by a spin coating process. Details of the preparation are described in [5].

For the deposition of the ETM, filtered air was conducted through a saturated atmosphere of water or IPA. A mass flow controller was used to regulate the flow velocity. The vapor was directed onto the sample through a heated copper pipe to avoid premature recondensation. The nozzle shape was designed to ensure uniform droplet growth for water and smooth homogeneous film generation if IPA was used.

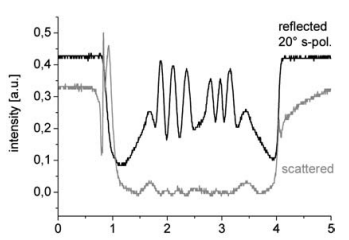

The condensation process was controlled by four different optical measurement systems. A scale drawing of the setup is displayed in Fig. 1. Two reflectometers, measuring at different angles, were used to determine the thickness of the liquid films. A photomultiplier, whose axis lay in a plane perpendicular to the cross section shown in Fig. 1, detected scattered light from the sample. This signal could be used to observe droplet growth and to determine the cleaning efficiency, since the scattered intensity is proportional to the number of particles on the surface. In addition, an optical microscope with a long working distance could be mounted above the sample to observe the condensation process visually.

Typical reflectometer and scattered light signals during a cleaning experiment with IPA are shown in Fig. 2. First, when the liquid began to attach at the interstices between the particles and the surface, the scattered intensity showed some characteristic structure, which depended on the particle size, and always involved a distinctive peak. Afterwards, the signal dropped steeply to an almost constant level. The bottom of this edge can be interpreted as the colloids being completely embedded in the liquid. In the experiments with constant film thickness, the cleaning laser was triggered at this point in time. The scattered intensity compared to the initial situation was reduced, because of the lower difference in the index of refraction between the particles and the surrounding medium. Note that the liquid layer covering the particles was not necessarily flat, since deformations of the film surface may have occurred at the colloids due to capillary forces.

Fig1

If water was chosen as the ETM, droplets were formed on the wafer. This caused an increase in the scattered intensity that had only a weak dependence on the size of the colloids on the surface. The oscillations in the reflectometer signal did not appear, but a characteristic drop to a constant level was observed. Therefore, measuring the amount of liquid on the surface with the method described above was impossible. However, equivalent conditions could be generated for all H2O-SLC experiments by triggering the laser pulse at the bottom of the drop in the reflectometer signal.

上一篇: 硅晶片的激光清洗:机制和效率