The direct deposition of carbon nanotubes on CMOS microhotplates is demonstrated in this paper. Tungsten microhotplates, fabricated on thin SOI membranes aside CMOS control circuitry, are used to locally grow carbon nanotubes by chemical vapour deposition. Unlike bulk heating of the entire chip, which could cause degradation to CMOS devices and interconnects due to high growth temperatures in excess of 500 ◦C, this novel technique allows carbon nanotubes to be grown on-chip in localized regions. The microfabricated heaters are thermally isolated from the rest of the CMOS chip as they are on the membranes. This allows carbon nanotubes to be grown alongside CMOS circuitry on the same wafer without any external heating, thus enabling new applications (e.g. smart gas sensing) where the integration of CMOS and carbon nanotubes is required.

Nanostructured materials for gas sensing have been of great interest because of their high surface to volume ratio. Conventionally, bulk materials such as tin oxide (SnO2) are widely applied as the sensing material, but in comparison to nanostructured alternatives, bulk materials have a smaller reactive area and hence typically lower sensitivities. The combination of microelectronic circuits, such as silicon CMOS devices, with nanostructured gas sensing materials enables ‘smart’ sensors to be made which are both smaller and cheaper to manufacture in a wafer-scale production environment. The integration of nanostructured sensing material with thermally isolated, low thermal mass on-chip heaters allows cycling of the sensing material at multiple temperatures to perform detection. As different gases have characteristic responses at different temperatures, such a device may be used like an electronic nose which not only has high sensitivity, but selectivity as well.

Carbon nanotubes (CNTs) are one of the most studied nanostructured materials being investigated for gas sensors. The advantageous properties of CNTs include their small size, high strength, relative chemical inertness,high electrical and thermal conductivity, and high specifific area. There are various reports in the literature of CNTs being used for NO2, NH3, CO, and O2 detection . Such sensors have relatively fast response and high sensitivity compared with conventional bulk material sensors. It is thus advantageous to couple CNT sensors with CMOS circuitry to build smart sensors. Although chemical vapour deposition (CVD) and plasma enhanced CVD (PECVD) are waferscale production techniques for CNTs, these have not been applied for this purpose because of the high temperatures involved in CNT growth which destroy the CMOS circuits. Chemical vapour deposition (CVD) is a common technique for depositing CNTs , and in this process, the substrates, coated with metal catalyst (Fe, Ni, Co), are heated to form islands at around 500 ◦C on a heater or furnace. Growth is typically initiated at an elevated temperature (750–850 ◦C) under a constant flflow of hydrocarbon gas. It is exposure to this high temperature, in excess of 500 ◦C, that damages CMOS transistors and causes interlayer breakdown between different levels of the circuit.

Fig1

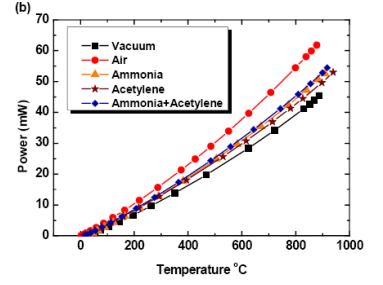

In this work, a novel local growth process was used to directly integrate carbon nanotubes with CMOS circuits on the same chip. A standard CMOS process was used to fabricate the transistors, which incorporated tungsten metallization for circuit interconnects and the microheaters. The microheaters were deliberately fabricated on membranes for thermal isolation. This also resulted in low-thermal-mass heaters which required very little power (milliwatts) to heat up, which could then be used to grow CNTs locally. CNTs were grown onto interdigitated electrodes and their electrical response determined using on-board CMOS circuits. This technique offers a route to integration of CNTs with CMOS technology, and is an ideal platform for smart gas sensing applications, where it is advantageous to combine CMOS circuitry with CNTs (or other nanostructured material) on a microheater platform.