Temperature is a critical parameter to be monitored and controlled in semiconductor processing. We use an ultrasonic technique where the temperature dependence of lowest order anti-symmetric Lamb wave velocity in the silicon wafer is utilized for in-situ temperature measurement in the 20 - 1OOO"C range. In almost all wafer processing steps, one or more layers of thin films are present on the wafers. The effects of these films on temperature sensitivity is investigated theoretically and experimentally. A theoretical model for Lamb wave propagation in general multilayered plates is developed using the surface impedance approach. This model is utilized to calculate the effects of anisotropy and thin films on temperature coefficients in semiconductor wafers. Calculations predict 2.38E-5 (1/"C) sensitivity for 10 cm (100) silicon wafer with 23% anisotropy. The same figures for gallium arsenide are 2.2E-5 (1/"C) and 8.7%. Thin film effects are considered for various materials commonly used in semiconductor processing. The density and shear elastic constants of film materials are found to be effective parameters in determining sensitivity figures. The frequency dependent sensitivity calculations show that it is possible to minimize effects of aluminum and silicon dioxide on silicon wafers by choosing the frequency-thickness products around 1.6 MHz-mni and 3.3 MHz-mm in temperature measurements, respectively. Using a simple propagation model, the time of flight sensitivity is also calculated and very good agreement is observed with experimental data obtained from a Rapid Thermal Processor.

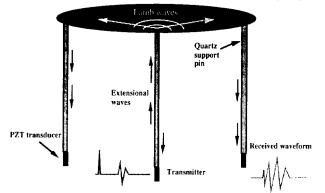

The ultrasonic wafer thermometry has introduced earlier as a new method having some advantage? over existing techniques. The schematic diagram for ultrasonic thermometry is shown in Fig. 1. The lowest order antisymmetric Lamb waves (A0 mode) are generated and detected by PZT-5H transducers bonded to the quartz support pins. The quartz support pins are used to guide extensional waves which couple to the A0 mode in the wafer at the Hertzian contact formed at the quartz pin - wafer interface. The tips of the quartz pins are rounded and polished to have a repeatable contact. The average wafer temperature along the path joining the transmitter and receiver is inferred from the time of flight measurement. Using a precision time interval counter, the time delay between a zero crossing in the echo signal coming from the tip of the transmitter and a particular zero crossing in the received signal is measured. Since the velocity of A0 mode is temperature dependent through the elastic constants of the wafer material, the time delay can be used to measure the temperature in-situ during many different semiconductor processing steps.

One of the main advantages of ultrasonic thermometry over optical techniques such as pyrometry or ellipsometry is that the ultrasonic waves are not very sensitive to thin films on wafers. This is an important property since different kinds of thin films exist or are grown on the wafer during most of the semiconductor processes. The techniques using pyrometry depend heavily on the emissivity which is a strong function of the films on the wafer. Ellipsometers can only be used with transparent films on wafers, making them unsuitable for measurements with metal films. The purpose of this paper is to investigate the effects of thin films and anisotropy of semiconductor wafers on iltrasonic thermometry in general. A theoretical methodology using the surface impedance approach for Lamb wave propagation calculation in anisotropic layered plates is presented. The calculations using this model is used to predict the temperature sensitivity of the ultrasonic thermometry in presence of various thin films on the wafer. Frequency dependence of the sensitivity figures are also discussed and used to minimize the influence of thin films. The results are then compared with experimental data obtained in a rapid thermal processor.

Fig1

When one or more thin layers are deposited at the surface of a relatively thick plate. the phase velocity of Lamb waves is affected depending on the material properties of the layers and plate. It is possible to exploit this sensitivity to measure thickness and properties of thin films. The algorithm described in the previuos section is used to calculate phase velocity of A0 mode for common thin film structures used in semiconductor processes. Fig. 6 shows the phase velocity variation of the A0 mode in a 0.5 mm (100) silicon wafer at 200 kHz with film thickness for different kinds of films. The variation is linear in this film thickness range, since the film is a small perturbation on the silicon plate. For aluminum and silicon dioxide, which have densities close to silicon and lower shear constant c,, the phase velocity has a positive slope with the film thickness. For silicon nitride, which is harder than silicon, the slope is 2.Xm/sec/pm indicating the stiffening effect. In the case of copper, the variation has a slope of -0.6m/sec/pm due to the loading caused by high density. The results indicate that the relative density and shear elastic constant cq4 of the films dominate the variation of phase velocity in this range. This can be attributed to the shear nature of A0 mode, which is predominantly a flexular wave.

A theoretical modcl tused on ttic surface irnpedilnce concept i\ developed to iiivehtigatc Lanib wave propagation in general anisotropic layered plates. This model is used to calculate the effects of temperature. thin films and their colnhined influence on phase velocity. The results indicate that for sonle film materials wch as silicon dioxide and alunlinurll. the phase velocity sensitivity can be minimized by particular choice of frequency lor temperature measurement. Also, for processes involving very thin filins in the order of 100-200 A thickness, the overall effect of the I'iInis can be neglected for temperattire iicctiracy in the range of +I"C. U\ing a simple model for the ultrasonic thermoinetry system. the experimental results are predicted with high accuracy. It is possible to extend these results to apply to iiiore conipliciited ultrasonic teniperature measurement problems such ;is temperature tomography.