This paper presents an experimental study of the aging of contaminated testwafers prepared for particle removal (cleaning) process evaluation insemiconductor wafer processing. Two wafer preparation techniques werecompared: a conventional wet technique in which bare silicon wafers weredipped in a particle-laden solution and then dried, and a dry technique inwhich particles were deposited from a dry particle-aerosol stream. The extentof wafer aging was quantified through cleaning tests. Wafers contaminatedwith silicon nitride and tungsten particles were cleaned on different daysfollowing particle deposition, and the variation in the cleaning efficiency withwafer storage time was monitored. The tests showed that the dry-depositedwafers aged very little compared to the wet-dipped wafers, particularly fortungsten particles. The low-aging characteristic of the dry-deposition processhas positive implications for the repeatability and consistency of testsinvolving new particle materials of interest such as copper and low-kdielectrics.

Particle removal (cleaning) is a critical aspect of semiconductor wafer surface preparation.Cleaning processes involving various mechanisms have been developed to date [1-4]. Theremoval of particles as small as 64 and 41 nm has recently been demonstrated [3-6]. Theefficiency of a cleaning process is determined through tests involving contaminated wafersprepared using a variety of techniques. The most common methods include immersion in asolution containing suspended particles [7] and exposure to a wet particle-laden aerosol [8]. Amore recent method involves exposure of wafers to a dry particle-aerosol stream [9]. Other noveltechniques have been developed, but are not yet well established. These include spin coating withparticle-laden solutions [10], exposure to saturated vapor of the contaminant [11], and exposureto reactive chemical solutions [12].

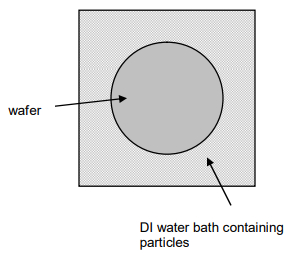

In the immersion technique (Figure 1a), the wafer is dipped in a deionized-water bath containinga dispersion of the test particles, and then spin-dried. In the wet-aerosol technique (Figure 1b), thewafer is exposed to a particle-laden deionized-water spray, then spin-dried. The two techniqueshave been found to yield fairly equivalent results in terms of particle-wafer adhesioncharacteristics, with the dipping method showing somewhat better wafer-to-wafer consistency inthe particle count and distribution than the aerosol technique [8]. In both cases, wafer aging isobserved, i.e., particle-wafer adhesion increases over time. Overall, the techniques are simple andsatisfactory for most cleaning tests aimed at process characterization.

Fig1

The overall low-aging characteristic of the dry-deposited wafers has positive implications forwafer cleaning process evaluation procedures. Wafers prepared using this technique can be storedfor reasonably long periods of time without requiring specially purged enclosures. A single batchof wafers can be split into separate lots and run at different times, with sufficient confidence thatthe tests are being conducted on equivalent wafer sets. The technique also reduces the repeatedefforts otherwise necessary to prepare fresh wafers, as with the wet-dipping technique, whenevercleaning tests are to be performed. The technique is also beneficial for tests involving the newmaterials such as Cu and low- dielectrics that are currently being introduced in semiconductordevice manufacturing. Particles made of these materials are likely to be softer than the Si3N4 or Wparticles tested in this study and conventional wet-dipping techniques can result in quite severeadhesion and wafer aging problems. It must also be noted that, overall, the dry-deposited wafersare easier to clean than the wet-dipped wafers and may not present as much of a challenge to thecleaning technique being tested. However, the challenge could be increased by depositing smallerparticles or particles of a softer material.