A method for cleaning etch residues that may include treatingan etched surface with an aqueous lanthanoid solution,wherein the aqueous lanthanoid solution removes an etchresidue that includes a majority of hydrocarbons and at leastone element selected from the group consisting of carbon,oxygen, fluorine, nitrogen and silicon. In one example, theaqueous solution may be cerium ammonium nitrate (Ce(NH)(NO)),(CAN).

With the continuing trend towards miniaturizationof integrated circuits (ICs), there is a need for transistors tohave higher drive currents with increasingly smaller dimensions. Part of processing advancements to provide Smallerdimensions in microelectronic devices includes advancements in etch processing. The spacer module can be considered most challenging, as all materials exposed to plasma etchremain on device. The spacer module refers to the formationof the gate sidewall spacer adjacent to the gate structure of asemiconductors devices, such as field effect transistors(FETs). Processing at the spacer module becomes even morechallenging for novel device geometries, such as Fin FETs,trigate semiconductor devices, and nanowire semiconductordevices.

In one embodiment, a method for cleaning etchresidues is provided that includes treating an etched Surfacewith an aqueous lanthanoid solution, wherein the aqueouslanthanoid solution removes an etch residue comprising amajority of hydrocarbons at and least one element selectedfrom the group consisting of carbon, oxygen, fluorine, nitrogen and silicon.

In another aspect, a method of forming a semiconductor device is provided that includes forming a gate structure on a channel region of a semiconductor Substrate. Thegate structure is formed using an etch process the forms anetch residue on at least a sidewall of a gate spacer to the gatestructure and an upper Surface of the semiconductor Substrateadjacent to the gate structure. A majority of the etch residuecomposition is comprised of hydrocarbons. The etch residuemay be removed with an aqueous lanthanoid solution comprising a majority of hydrocarbons and least one elementselected from the group consisting of carbon, oxygen, fluorine, nitrogen and silicon.

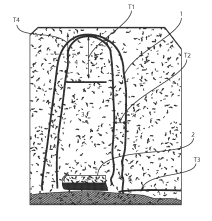

Fig1

Detailed embodiments of the claimed structures andmethods are disclosed herein; however, it is to be understoodthat the disclosed embodiments are merely illustrative of theclaimed structures and methods that may be embodied invarious forms. In addition, each of the examples given inconnection with the various embodiments are intended to beillustrative, and not restrictive. Further, the figures are notnecessarily to scale. Some features may be exaggerated toshow details of particular components. Therefore, specificstructural and functional details disclosed herein are not to beinterpreted as limiting, but merely as a representative basis forteaching one skilled in the art to variously employ the methods and structures of the present disclosure. For purposes ofthe description hereinafter, the terms “upper”, “lower,“right”, “left”, “vertical”, “horizontal”, “top”, “bottom', andderivatives thereof shall relate to the embodiments of thedisclosure, as it is oriented in the drawing figures. The term"positioned on’ means that a first element, Such as a firststructure, is present on a second element, such as a secondstructure, wherein intervening elements, such as an interfacestructure, e.g. interface layer, may be present between the firstelement and the second element. The term "direct contact’means that a first element, such as a first structure, and asecond element, Such as a second structure, are connectedwithout any intermediary conducting, insulating or semiconductor layers at the interface of the two elements.