Solution growth continues to be one of the most powerful techniques for the production of single crystals for basicandappliedresearch. It is a versatile technique that allows for the growth of congruently andincongruently meltingmaterials with equal ease. The primary requirement for growth is that there be an exposedprimary solidification surfacein the appropriate equilibrium alloy phase diagram. In this paper, we will review some of the systems that we haveappliedthis technique to over the past several years. These range from binary andternary intermetallic compounds suchas RFe2 (R=Rare earth) andRT2Ge2 (T=Ni andCu) to the refractory RNi2B2C family of magnetic superconductorsto several families of quasicrystals. In each case, specific nuances of the relatively simple growth technique will bediscussed. # 2001 Elsevier Science B.V. All rights reserved.

Single crystal samples allow for the measurement of the intrinsic properties of materials. Inspecific, they generally provide samples with lessstrain, higher purity, fewer grain boundaries, andnatural growth habit. For basic studies of theelectronic, magnetic, thermodynamic and structural properties of new or exotic materials the size ofsingle crystals requiredrarely exceeds a cubiccentimeter andoften (with the exception ofinelastic neutron scattering) crystals with dimensions of several mm on a side are more thanadequate. Given that the majority of materials areincongruently melting, a technique that can grow awide variety of congruently and incongruentlymelting materials with equal ease, with relativelysimple equipment, in rather short time scales, is ofgreat desirability. Growth from high-temperaturemetallic solutions is just such a technique. Inaddition it uses relatively small amounts ofmaterials, making it much more economic thantechniques such as Bridgman or Czochralski (CZ)growth, both of which require more substantialquantities raw material.

In this paper, we will review several recentexamples of single crystals (or quasicrystals) thathave been grown from metallic solutions. The emphasis will be on showing the versatility of thistechnique as well as highlighting advances thathave been made in temperature range, flux, orcrucible design over the past decade. This papershouldbe consideredas an extension of two earlierpapers publishedon this technique by Fisk andRemieka [1], andCanfieldandFisk [2].

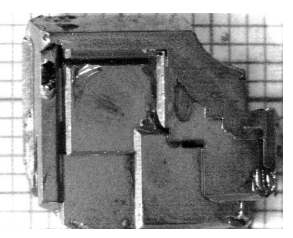

Given the reactivity of certain elements withAl2O3 (excessive Ce andMg for example), a Tacrucible is sometimes needed. So as to allow forthe decanting of the excess melt from the growncrystals a sealedTa crucible with a built-in straineris used. A simple, but effective version of such acrucible is referredto as a ‘‘3-cap crucible’’ becauseit can be made from a length of Ta tubing andthree Ta caps, made of Ta sheet that have beenmachinedto just fit inside of the Ta tube. One ofthe caps is arc-welded into the tube, closing it andcreating a crucible, then the material is placedintothe bottom of the crucible andthe secondcap,with holes drilled through it, is crimped into placejust above the level of the solidmaterial. Finally,the thirdcap is arc weldedinto place, sealing thecrucible. Once the growth is completedthe cruciblecan be invertedfor decanting.

Fig1

Solution growth provided the first single grains(andto a large extent the first single phase)samples of these materials [5]. With single grainsof the I-RMgZn materials a thorough investigation of magnetic andelectronic properties waspossible. The I-RMgZn series provides an excellent example of the spin glass groundstate [7] andalso exhibits many of the transport propertiesassociatedwith metallic glasses. Whereas, it waspreviously thought that disorder was a necessarycondition for the observation of spin glass ormetallic glass like behavior, it is now experimentally clear that a highly ordered, aperiodicarrangement of atoms is sufficient. To this extent,the quasicrytalline samples offer a more reproducible way of examining these low-temperaturestates.

下一篇: 旋涂法沉积氧化铝薄膜c硅片表面钝化