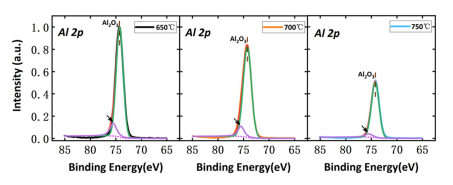

In the present work, alumina gel was developed for passivating silicon wafers. The alumina gel was prepared by sol–gelmethod with aluminum sec-butoxide as precursor. After coating, rapid thermal process (RTP) was conducted to activate thepassivation efect. X-ray photoelectron spectroscopy and C–V curve were executed to evaluate flm properties. The peak at74.35 eV confrmed the formation of Al2O3. Meanwhile, a small peak at low binding energy decreased with the growth ofannealing temperature, which was ascribed to the escape of hydrogen, leading to the decline of efective lifetime after 700 °C.The highest fxed charge (Qf) of −1.16e12 cm−2 and superior interface defect density at mid gap (Dit) of 1.98e12 cm−2eV−1were obtained at the annealing temperature of 700 °C, contributing to the highest efective minority carrier lifetime of 292µs. The present work will be helpful to provide a more cost-efective technique for Al2O3 passivation.

In order to suppress the recombination in wafer surface,many passivation flms, including TiO2, SiO2, SiNx, andAl2O3, have been presented [1–4]. Among them, Al2O3has been widely applied for the back-surface passivation inindustrial passivated emitter and rear cell (PERC) benefting from the superior surface chemical passivation as wellas the feld efect passivation induced by the fxed negativedensity [5–7].

The sol–gel synthetic technique has been applied forfabricating Al2O3 flm by some researchers. Two routesfor fabricating sol–gel are generally described in the document, which are polymeric sol–gel route and colloidal sol–gel route. [12] The former is utilizing the chemistry ofmetal–organic precursors in organic solvents, while the latteris applied colloidal chemistry in aqueous media. Notice thatpolymeric sol–gel route is much better suited for the multiple components membrane [13]. Sol–gel method was alsoapplied to fabricate alumina gel in this paper, but insteadof environmentally hazardous organic solvents water wasimported as the solvent. Considering the alumina precursor,aluminum isopropoxide is a common option [14]; however,the relative low water solubility of aluminum isopropoxidecan lead to unmanageable transparency and particle size ofthe alumina gel. Aluminum sec-butoxide becomes an interesting alternative due to the superior water solubility.

Here aluminum sec-butoxide was applied as the precursor to fabricate alumina gel. The XPS measurement wasintroduced to study the typical element state in the annealedAl2O3 flm. Furthermore, the impact of thermal treatmenton the passivation property was investigated systematically, which was further demonstrated by the fxed negativecharges Qf [15] and interface defect density at mid gap Dit[16, 17] extracted in C–V curves. The result is helpful todeepen the understanding of the passivation mechanism ofalumina gel.

Fig1

The Al 2p peak with the increasing temperature increasedon full width at half maxima (FWHM). It was thought thatthis related to the presence of OH radicals in the flms.According to the observation by Alexander [19], whoshowed that after removing the OH in AlOOH by heattreatment, the FWHM of both the Al 2p and O 1s peaksincreased, with a slight movement of the O 1s peak to lowerbinding energy. The Al–OH wAS converted into Al2O3structure, so the chemical passivation efect declines.

上一篇: 金属间化合物单晶和准晶的高温溶液生长