This paper reports that the low-frequency noise inp-channel MOSFETs fabricated on (110) and (100) crystallographic oriented silicon is related to the microroughness of the silicon surface. Since the conventional RCA cleaning process makesthe surface rough, especially in the case of (110) orientation, theauthors developed the so-called 5-step room temperature cleaningprocess that does not use alkaline solution. The combination ofthis new cleaning process with the microwave-excited high-densityplasma oxidation process for the formation of the gate oxide,instead of the standard 900 ◦C thermal oxidation process, leadsto a reduction of the microroughness and a drop in the 1/f noiselevel of more than one decade. Furthermore, this reduction is notonly observed for the (110) orientation but also seen, albeit to amuch lesser extent, for (100) if it is treated in the same way.

The origin of the 1/f noise has not yet been understoodand is still being discussed within the scientific community[7]–[10]. However, even if the schools of thought are in agreement that 1/f noise can be explained by the fluctuation of conductivity, one school attributes this noise to a bulk phenomenoninduced by the mobility fluctuation in the lattice [7], whilethe other school explains it by the fluctuation in the number of carriers caused by interface traps [8]. During the 1990s, athird theory was developed that is a combination of both of theabove models that included mobility and number fluctuations.

In the quest for the realization of future high-speed analogand digital circuits, the improvement of the working frequencyand the reduction of the signal/noise ratio are two of the parameters of prime importance. Although the current drivabilityof pMOSFETs fabricated on (110)-oriented silicon is 2.5 timeslarger than that on (100) [11]–[14], the 1/f noise level is stilltoo high to establish it as a viable competitor or even a futurereplacement for the current CMOS technology on (100) silicon.

The alkaline solution used during the conventional RCAcleaning process before the fabrication of the gate oxide makesthe silicon surface rough [15], [16]. This is especially true for(110) surfaces. Therefore, we have developed an alkali-free5-step room temperature cleaning process [17] that producesa better quality surface that can be further processed to producedevices with suppressed low frequency noise levels.

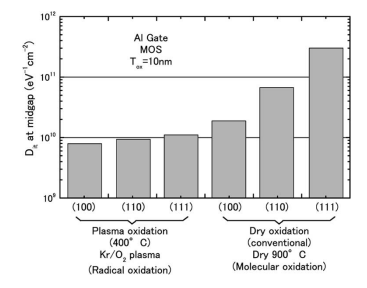

The purpose of this paper is to show that the suppressionof the 1/f noise in pMOSFETs can be achieved for (110)and (100) orientations due to the improvement in the microroughness resulting from the alkali-free cleaning process. Consequently, it is demonstrated that the 1/f noise is closely relatedto the quality of the Si/SiO2 interface [18]. Furthermore, aneven stronger reduction of the noise can be obtained when usingthe 5-step cleaning in combination with the microwave-excitedhigh-density plasma oxidation process [19] for the fabricationof the gate oxide instead of the standard 900 ◦C thermaloxidation process. Also, it is worth noting that the suppressionin the 1/f noise level is much more pronounced for the (110)orientation, meaning that the divide between the noise levels of(110) and (100) pMOSFETs has also been greatly reduced.

As a replacement for RCA cleaning, we developed the alkalifree 5-step room temperature cleaning process. As explained inFig. 4, this new technique has a very simple procedure, withonly one rinse at the end of the cleaning. Further, it can becarried out without any temperature elevation in less than 5 min.

Fig1

The significant change in noise level has its origin in thecleaning process and the resulting surface quality, and in particular the change in the microroughness. In turn, this can beattributed to the increased degradation of the (110) surface,caused by the alkaline solution used during the RCA cleaningcompared to the lower degradation of the (100) surface underthe same conditions. Thus, the choice of the cleaning methodcan have a significant effect, which may be amplified, in termsof the interface quality and the resulting 1/f noise level duringthe gate formation step. This will be especially true in the caseof thermal oxidation.

上一篇: 用于外延应用的原位低温硅表面清洁的氯蚀刻

下一篇: 熔融石英的湿法蚀刻:一项多重研究