The machining process of transparent materials using the laser inducedbackside wet etching (LIBWE) procedure was studied. In the course of this,experimental investigations and numerical calculations were carried out.Fused silica plates were irradiated by an ArF excimer laser, using anaphthalene–methyl methacrylate solution as an absorbing liquid(concentration 0.85 mol dm−3, absorption coefficient at 193 nm52 200 cm−1). The etch rate dependence on the applied laser fluence (variedfrom 110 to 860 mJ cm−2) was derived from the etch depths, measured usingan atomic force microscope (AFM). The etch rate was found to be4.7–49.5 nm/pulse, depending on the laser fluence. The surface morphologyof the etched edges was also investigated by AFM. A fast photographicarrangement was used for time resolved observation of bubble developmentin the liquid absorbent, which is an important phenomenon of LIBWE. Theinternal pressure of the expanding bubbles was calculated using recordedsnapshots. It was found to be 22–120 MPa 17.2 ns after the excimer pulsepeak. The one-dimensional heat flow equation, including the melting of thetreated fused silica layer and the vaporization of the absorbing solution, wassolved using the finite difference method. The surface temperature of thefused silica was found to be a maximal 17.2 ns after the excimer pulse peak.Based on our results, we present a possible interpretation of the LIBWEprocedure of fused silica.

Micromachining of transparent materials is very extensivein modern micro-optics. One of the most advantageoustechniques for micromachining of transparent dielectricmaterials is laser induced backside wet etching (LIBWE).The benefits of this technique, compared with other methods,include the very low threshold fluence, well defined debris andcrack free micropatterns, and good controllability (very preciseetch depth control). Fresnel lenses [1] and diffractive gratingsin fused silica [2] can be fabricated using this procedure.

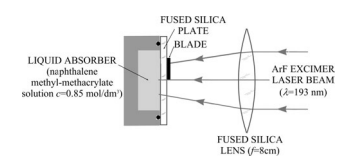

The following is a brief description of the procedure: oneside of a transparent dielectric material is in contact with a liquid absorber having a high absorption coefficient at thewavelength of the irradiating laser. This liquid is illuminatedthrough the transparent target by a laser beam. The contactingliquid layer, with a thickness corresponding approximately tothe light penetration depth, absorbs the pulse energy, resultingin an extreme high temperature in it and in the contactingsurface layer of the solid sample. High pressure vapour bubblesform and expand in the liquid, inducing etching of the targetsurface. The LIBWE procedure has been extensively studied inthe last decade. Ding and co-workers [3] have investigated theformation and temporal evolution of the bubbles and calculatedtheir internal pressure without considering some importantphysical properties of the absorbing liquid (compressibility,viscosity and surface tension). They have emphasized the importance of the high pressure bubbles in the etching process.The maximal temperature of the boiling absorber layer hasbeen estimated roughly by Wang et al [4]; however, they couldnot calculate the temperature of the solid target.

In spite of the several studies, the mechanism ofLIBWE has not been described precisely since some physicalparameters (the temperature of the solid target and theliquid absorbent, the pressure above the surface layer of thetransparent material) are difficult to measure directly duringthe etching process. These values would be very important fordetailed interpretation of the wet etching process. The thermaleffects (heat diffusion, drastic warming up and melting) andtheir consequences (high pressure bubble expansion, strongmechanical effects) play a significant role in LIBWE. In ourstudy we planned to determine the most significant etchingparameters (etch rate and morphology) and calculate thetemperature of the surface layer of the fused silica for thecorrect interpretation of the LIBWE procedure. The mainquestion was whether the transparent target melted or notduring wet etching. The mechanical effects caused by thebubble expansion also play a key role in the micromachiningtechnique investigated. These effects can be characterized bythe pressure inside the bubbles. This is determined by therelevant physical parameters of the absorbing liquid, and thedimension and shape of the originating bubbles, which wereobserved using a fast photographic arrangement.

The inner surface of the fused silica plate contactingthe absorbent liquid was illuminated by a N2 laser pumpeddye laser (Coumarin153, λ = 543 nm, FWHM = 1 ns).The bubbles were observed and recorded using a microscope–video camera system. The applied excimer laser fluence wasvaried between 70 and 900 mJ cm−2, and the delay betweenthe excimer and the exposing dye laser pulses was changed inthe range 1–300µs.

Fig1

The threshold fluence for LIBWE of fused silica was assumedto be between 110 and 210 mJ cm−2 since in our earlierexperiments [5] etching was not observable at 110 mJ cm−2,while it occurred at 210 mJ cm−2. Figure 3 shows the fluence–etch rate (the thickness of the layer removed by a singlelaser pulse) function. Two lines with different slopes werefitted to the measured data. The etch rate increased slowlybelow a fluence value of 330 mJ cm−2 and rapidly above it.This breakpoint was also observed in other studies, usingan aqueous solution of Np(SO3Na)3 [3] or a pyrene–acetonesolution.