Abstract

This article presents a cost-efective ultraviolet-ozone cleaner (UV/O3 Cleaner) for surface pre-treatment of substrates in the feld of semiconductor technology. The cleaner consists of two chambers, the upper one contains the electronics, including the time counter. The lower chamber contains the two UV sterilisation lamps and a UV refector of anodized aluminium, which confnes the area of high Ozone concentration in the area of interest. The device is successfully used for surface cleaning and modifcation of diferent materials. To this end, the two important wavelengths 253.7 nm (excitation of organic residues) and 184.9 nm (production of ozone from the atmospheric environment as a strong oxidant) were frst detected. The efectiveness of UV/O3 cleaning is demonstrated by improving the properties of indium tin oxide (ITO) for OLED fabrication. The contact angle of water to ITO could be reduced from 90° to 3° and for diiodomethane, it was reduced from 55° to 31° within the 10 min of irradiation. This greatly improved wettability for polar and non-polar liquids can increase the fexibility in further process control. In addition, an improvement in wettability is characterized by measuring the contact angles for titanium dioxide (TiO2) and polydimethylsiloxane (PDMS). The contact angle of water to TiO2 decreased from 70° to 10°, and that of diiodomethane to TiO2 from 54° to 31°. The wettability of PDMS was also greatly increased. Here, the contact angle of water was reduced from 109° to 24° and the contact angle to diiodomethane from 89° to 49°.

1 Introduction

The pre-treatment and cleaning of substrate surfaces have established themselves as an important step in device fabrication, particularly in the electronics, semiconductors industries, food processing, wastewater purification and many other fields. Cleaning and modification of surfaces for removing particles and organic, molecular, metallic or microbiological contaminations can be achieved by a variety of different methods, whereby one can distinguish in particular between wet-chemical and dry cleaning methods.

2、 Materials and methods

2.1 Preparation of the TiO2‑surfaces

TiO2 layers were deposited on Silicon Wafers by plasmaenhanced atomic layer deposition (PEALD) with the ALD150 system from the company FHR, Germany. Due to the plasma support in the layer deposition, the layer growth was realized at low temperatures and a high-density layer was produced simultaneously. The low temperature enabled the fabrication of amorphous TiO2 layers.

3 Results and discussion

3.1 UV/O3‑treatment

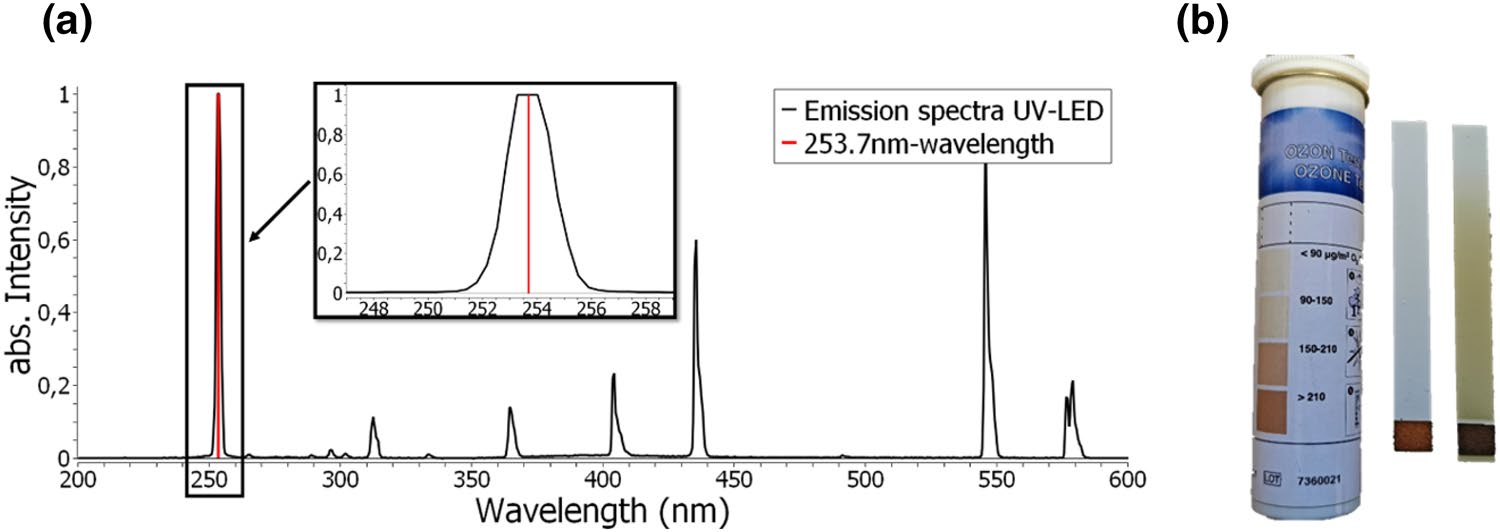

The UV/O3 treatment of the substrates was carried out in our cost-efective cleaner. The emission spectrum in the range from 200 to 600 nm of the two fuorescent lamps are shown in Fig. 1a. The spectral line distribution is similar to that of a mercury vapour lamp (compare to ). In particular, the peak at 253.7 nm was important for the possibility of removing biogradable contamination on the surfaces and was detected with the spectrometer. The ozone test strip consists of a plastic strip with a test paper, which reacts with a colour change from white to brown depending on the ozone level. After an exposure time of 10 min, without direct UV radiation, the test feld was compared with the manufacturer’s colour scale. The test strips were placed at diferent places. All test strips in the immediate vicinity and within the chamber turned dark brown. The discolouration went beyond the measuring range of the scale, which indicated an ozone concentration of well over 210 µg/m³. As an example, two test clearances are shown in Fig. 1b, where the lighter test strip was on top and the darker test strip was in the chamber. Thus, the emission of the wavelength of 184.9 nm could be detected. Due to the strong ozone development, the UV/O3-cleaner should only be operated with a fume cupboard.

Fig. 2 a Emission spectra of the used UV lamps. b Colour change of the ozone test swipe with the colour scale from white to brown

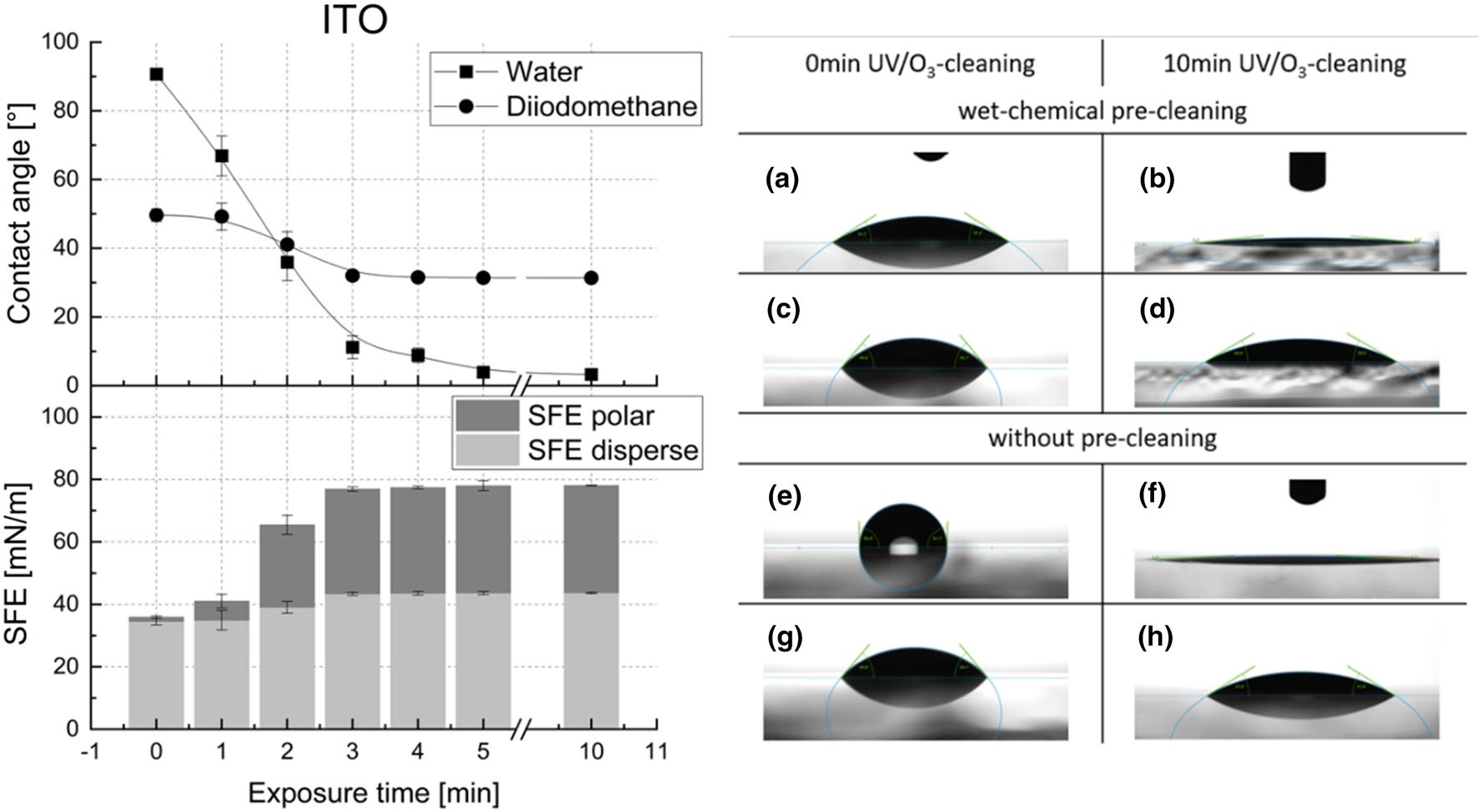

The time-dependent measurement of the contact angles between a 1 µl water droplet and an uncleaned ITO substrate and the SFE values, as well as the pictures are shown in Fig. 2. An increase in wettability is visible. The contact angle of water decreases almost continuously with the start of the UV/O3-treatment and drops from above 90° to a contact angle below 10°. After an exposure time of 10 min, the contact angle of 90° in untreated ITO has fallen to 3.3°. This corresponds to a superhydrophilic surface and the change in surface energy is also present. With a surface energy in the untreated stage of 36 mN/m, it doubles the maximum of 78 mN/m after about 5 min. In particular, the increase in the polar proportion from 1.44 to 34.38 mN/m is responsible for the increase in wettability. The disperse fraction increases from 34.48 to 43.63 mN/m, respectively. The measurement uncertainty for all values, outside the range of the strong drop, is below ±1°, about±3° between 1 and 2 min.

Fig. 3 Left side: time-dependent change of the surface wettability for water and diiodomethane and the corresponding surface free energies, whereby the total SFE is the sum of the polar and dispersive fractions, for ITO without pre-cleaning; right hand side: picture of the contact angles. a contact angle of water with wet-chemical pre-cleaning and without UV/O3-cleaning, b contact angle of water with wet-chemical pre-cleaning and 10 min UV/O3-cleaning, c contact angle of diiodomethane with wet-chemical pre-cleaning and without UV/O3-cleaning d contact angle of diiodomethane with wet-chemical pre-cleaning and 10 min UV/O3-cleaning, e contact angle of water without wet-chemical pre-cleaning and without UV/O3-cleaning, f contact angle of water without wet-chemical pre-cleaning and 10 min UV/O3-cleaning, g contact angle of diiodomethane without wet-chemical pre-cleaning and without UV/ O3-cleaning h contact angle of diiodomethane without wet-chemical pre-cleaning and 10 min UV/O3-cleaning.

4 Conclusion

As part of the study, the functionality of a simple, self-built and cost-efective UV/O3 cleaner was investigated. To be used as an alternative to commercially available devices, the system must have the following infuences on substrate surfaces. This includes the removal of organic residues and the excitation of the surface, whereby, for example, the wettability of the substrate is changed. To achieve this efect, the emission of two wavelengths for cleaning and ozone fabrication is necessary. Photons with a wavelength of 253.7 nm are absorbed by hydrocarbons (the main component of organic materials). These excited molecules can then react with ozone or atmospheric oxygen and thus be dissolved from the surface. The second important wavelength is 184.9 nm, which is responsible for the production of ozone. This reacts with the organic residues on the substrate or with molecules close to the surface, whereby the chemical structure of the surface and thus, for example, the wettability can be infuenced.

下一篇: 微流控芯片制造材料