Abstract: Enhancing the levelness of the wafer surface can be achieved by increasing the homogeneity of the radial motion speed of the wafer surface in relation to the polishing pad. In order to analyze the effects of the inner and outer pin ring rotational speeds, the equipment structure size, and the upper and lower polishing pad rotational speeds on the uniformity of the radial velocity distribution of the wafer surface with respect to the polishing pads, kinematics equations of the wafer surface relative to the polishing pads were constructed based on the kinematics of the planetary wheel system. The wafer's motion state with respect to the polishing pad is composed of two processes: rotation and revolution. Rotation is the reason for the uneven radial distribution of the wafer's surface speed; The surface velocity of the wafer is optimally dispersed with respect to the polishing pad when the polishing pad's rotational speed equals that of the planetary wheel; Increasing the polishing pad speed can result in a more equal speed distribution in the direction of the wafer radius with respect to the pad when the ratio of the outer pin ring speed N4 to the inner pin ring speed N3 is less than 1; The velocity homogeneity of the wafer in the radius direction can be enhanced by increasing the eccentricity of the wafer with regard to the planetary wheel and the distance between the 1 center of the planetary wheel and the inner pin ring.

1 Introduction

Chemical Mechanical Polishing (CMP) process is an essential step in the production of silicon wafers, which uses mechanical grinding and chemical reaction to remove impurities . One of the key methods for smoothing the surface of large-diameter silicon wafers is the Double Side Chemical Mechanical Polishing (DSP) process, in which the silicon wafers are polished synchronously on both their upper and bottom surfaces by the combined action of their upper and lower polishing pads.

2. Mathematical modeling of the kinematics of DSP

2.1 Mathematical Modeling of Wafer Motion Paths for DSP Processes

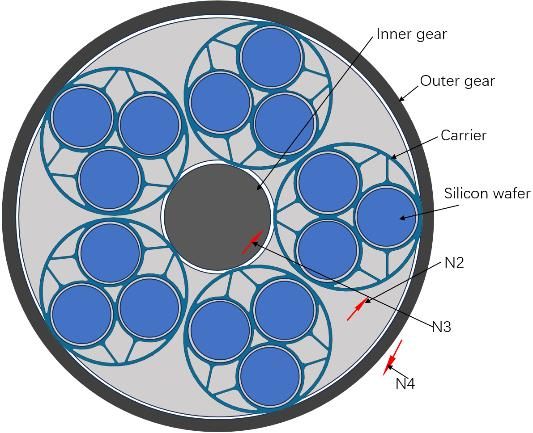

The planetary wheel drives the wafer in the DSP process by exhibiting a composite motion of rotation and revolution while the top and lower polishing pads rotate at opposite angular velocities. As seen in Fig.1, the inner pin ring rotation speed N3, the outer pin ring rotation speed N4, the lower polishing pad rotation speed N2, and the upper polishing pad rotation speed N1 all work together to define the trajectory of a point on the wafer on the polishing pad.

Fig.1 Schematic diagram of DSP geometric structure

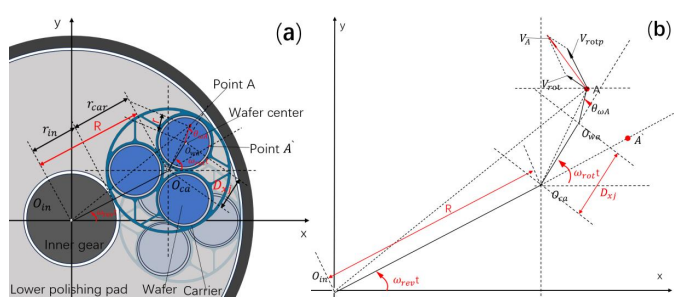

Various spots on the wafer have various motion trajectories in relation to the polishing pad. The difference between the velocity at the center of the wafer and the velocity at its edge can be computed by building a mathematical model of the DSP process' kinematics, as illustrated in Fig.2. Fig.2(a) shows the schematic diagram of the motion process of point A, and Fig.2(b) shows the schematic diagram of the velocity synthesis of point A. In order to streamline the model, the wafer's rotation is disregarded.

Fig.2 Schematic diagram of DSP motion process (a) and speed synthesis (b)

2.2 Mathematical model validation

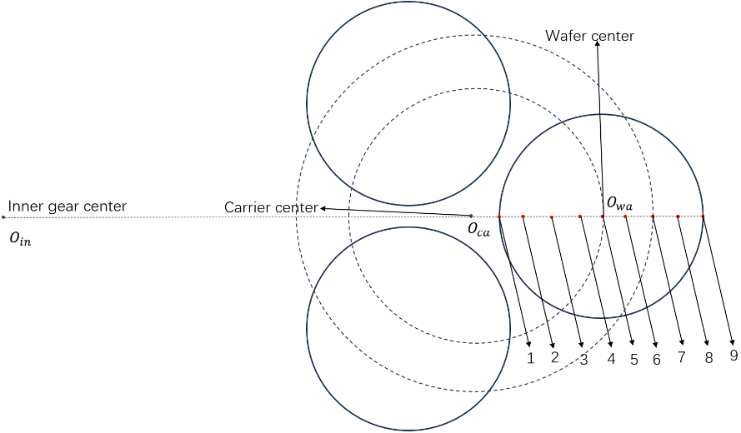

The mathematical model developed in this study is compared with the data gathered using kinematic analysis software to confirm the accuracy of the wafer motion mathematical model. Nine locations on the wafer's diameter are selected as benchmarks for comparison. (The locations are shown in Fig.3 and Tab.2) As a comparison indicator, the average speed of these nine reference locations over a single cycle in relation to the polishing pad is utilized. Tab.3 displays the speed parameters and mechanical structure dimensions that were used in the calculations. The values in Tab.3 are the base operating conditions, and they are defined as being positive in a counterclockwise orientation.

Fig.3 Schematic diagram of the position of the wafer surface velocity reference point

3. Results and discussions

The wafer's state of motion with respect to the polishing pads, and consequently the wafer surface velocity uniformity, are determined by the combination of the previously mentioned upper polishing pad rotation speed (N1), lower polishing pad rotation speed (N2), inner pin ring rotation speed (N3), outer pin ring rotation speed (N4), as well as the mechanical structure dimensions R and Dxj . As can be seen from Section 3, the upper and lower polishing pad rotational speeds should be opposite, and the rotational angular velocity of the lower polishing pad should be equal to the rotational angular velocity of the planetary wheel rotation. This research aims to examine the effects on the wafer surface velocity uniformity of the inner - outer pin ring rotational speed ratio N3/N4, the upper polishing pad rotational speed N1, and the structural dimensions R and Dxj, respectively.

4. Conclusions

As the length of the wafer's trajectory with respect to the polishing pad is positively connected with the total amount of material removed from the wafer surface and its flatness. This study proposes an index factor to characterize the uniformity of wafer surface speed distribution. It also builds a mathematical model to analyze the effects of three parameters—the inner-outer pin ring speed ratio, the polishing pad speed, and the size of the equipment structure—on the radial distribution of wafer surface speed. The findings are as follows:

(1) The planetary wheel's contribution to the polishing pad's rotation speed causes a speed differential between the wafer's center and edge. By enhancing the planetary wheel's impact on the pad's revolution, the rotational effect is weakened, which improves the wafer surface's speed uniformity.

(2) The lower polishing pad speed N2 should be equal to the planetary wheel rotational angular velocity, in the inner pin ring speed N3 and outer pin ring speed N4 ratio of 1, there is a critical condition, N3/N4 is greater than 1, reduce the upper polishing pad N1, N3/N4 is less than 1, increase the upper polishing pad N1, which is conducive to the improvement of the wafer surface speed uniformity.

(3) Increase the distance from the center of the planetary wheel to the origin and the eccentricity of the wafer with respect to the planetary wheel, which is conducive to improving the velocity uniformity of the wafer surface.

A number of variables, including the polishing fluid's inlet flow rate and the depth of the polishing pad grooves, can alter the wafer surface morphology during processing and result in variations in the quantity of material removed from both sides of the wafer. In order to provide a theoretical framework for bettering DSP processing settings, this research focuses on the factors influencing the radial distribution of wafer velocity with respect to the polishing pad.

上一篇: 蚀刻对薄膜单晶铌谐振器的影响

下一篇: 先进的氮化镓衬底化学机械抛光技术