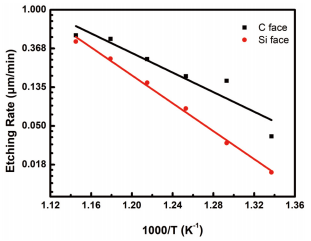

Abstract: Molten-alkali etching has been widely used to reveal dislocations in 4H silicon carbide (4H-SiC), which has promoted the identification and statistics of dislocation density in 4H-SiC single crystals. However, the etching mechanism of 4H-SiC is limited misunderstood. In this letter, we reveal the anisotropic etching mechanism of the Si face and C face of 4H-SiC by combining molten-KOH etching, X-ray photoelectron spectroscopy (XPS) and first-principles investigations. The activation energies for the molten-KOH etching of the C face and Si face of 4H-SiC are calculated to be 25.09 and 35.75 kcal/mol, respectively. The molten-KOH etching rate of the C face is higher than the Si face. Combining XPS analysis and first-principles calculations, we find that the molten-KOH etching of 4H-SiC is proceeded by the cycling of the oxidation of 4H-SiC by the dissolved oxygen and the removal of oxides by molten KOH. The faster etching rate of the C face is caused by the fact that the oxides on the C face are unstable, and easier to be removed with molten alkali, rather than the C face being easier to be oxidized.

1. Introduction

4H silicon carbide (4H-SiC) has shown great success in high-power and high-frequency electronics, owing to its excellent properties such as a wide bandgap, high thermal conductivity, high-electron saturation velocity, and high chemical stability. Despite the great success of 4H-SiC in electrical vehicles and photovoltaic converters, the potential of 4H-SiC in ultra-high-power electronics has not been fully addressed due to the high density of dislocations that deteriorate the device performance and exert reliability issues[. For example, dislocations have been found to increase the leakage current of 4H-SiC-based high-power devices. Although most of basal plane dislocations (BPDs) in 4H-SiC substrates are converted to threading edge dislocations (TEDs) during homoepitaxy, the residual BPDs in homoepitaxial 4H-SiC still trigger bipolar degradation of 4H-SiC-based bipolar devices. Therefore, discriminating the type of dislocations and providing accurate dislocation density is critical to the application of 4H-SiC substrates and epitaxial layers.

Molten-alkali etching has been widely used to reveal dislocations via the preferential etching of dislocations in 4H-SiC. By removing strained atoms surrounding the dislocations lines, molten-alkali etching is capable of forming characteristic etch pits of different types of dislocations in 4H-SiC. It was proposed to distinguish threading screw dislocations (TSDs),TEDs, and BPDs by the two-dimensional shape and size of etch pits. This usually needs additives to enlarge the degree of distinction among the etch pits of TSDs, TEDs, and BPDs. Taking a further step, we have found that the TSDs, threading mixed dislocations (TMDs), TEDs and BPDs can be discriminated by the incline angles to the molten-alkali-etchinginduced pits. This facilitates the accurate statics of dislocation density in 4H-SiC. However, this approach is only effective to the (0001) Si face of 4H-SiC. The revelation of dislocations on the C face usually needs higher energy approaches, such as alkali vapor etching and microwave plasma etching . Researchers attribute the anisotropic etching of 4H-SiC to the different activation energy between the Si face and the C face of 4H-SiC. However, the underlying mechanism for the anisotropic etching of 4H-SiC is still ambiguous. This hinders the optimization of the etching and dislocation revealing of 4H-SiC.

2. Experimental section

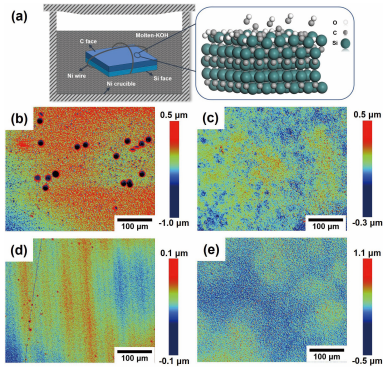

High-purity semi-insulating (HPSI) 4H-SiC single crystals were grown by physical vapor transport (PVT) technology. The growth temperature and growth pressure were set in the range of 2200−2300 °C and 1−10 mbar, respectively. 4H-SiC wafers were sliced and mechanically polished on both sides. The wafers were cut into 20 × 20 mm2 samples prior to molten-alkali etching. Molten-alkali etching experiments were performed at temperatures from 475 to 600 °C with the duration of 60 min in a nickel crucible. In order to measure the etching rate of the C face and Si face separately, we stacked two 4H-SiC samples together, and wrapped them tightly with a nickel wire. This exposed the Si face and C face of the top and bottom 4H-SiC sample to molten KOH, respectively [Fig. 1(a)]. After molten-KOH etching, the 4H-SiC samples were ultrasonically cleaned with deionized water and 15% hydrochloric acid solution to remove residual KOH contamination on the surface of 4H-SiC samples. The samples were then cleaned by acetone, ethanol, and finally dry with nitrogen gas. The etching rates of the Si face and C face of 4H-SiC were calculated by dividing the change of sample thickness with the etching duration.

Fig. 1. (Color online) (a) Schematic diagram showing the experimental setup of molten-KOH etching, and the oxide-removal mechanism of 4H-SiC. The surface morphologies of the molten-KOH-etched 4H-SiC samples: (b) Exposed Si face, (c) protected C face, (d) protected Si face, and (e) exposed C face.

After molten-KOH etching, the surface morphologies of the Si face and C face were observed by scanning white light interferometry (SWLI, ContourX-200, Bruker). XPS measurements were conducted with an ESCALAB Xi+ system, using an Al K monochromatic radiation of 1486.6 eV. The vacuum condition for the test was 2 10−10 mbar, and all the binding energies of the XPS date were calibrated with the C 1s peak at 284.8 eV.

3. Results and discussion

Figs. 1(b)–1(e) show the surface morphologies of the stacked 4H-SiC samples after molten-KOH etching at 475 °C. As shown in Fig. 1(b), the exposed Si face of the top 4H-SiC samples show the high density of the dislocation-related etch pits. For the protected C face of the top 4H-SiC sample and the protected Si face of the bottom 4H-SiC sample, there are almost no etch pits, indicating that the inner sides of the 4HSiC samples are protected from being etched [Figs. 1(c) and 1(d)]. The situation for the molten-KOH etching of the C face of the exposed bottom 4H-SiC sample has a relatively smooth surface [Fig. 1(e)]. This is caused by the isotropic etching of the C face prevailing over the preferential etching along dislocations .

Fig. 2. (Color online) Temperature dependence of the etch rates of the Si face and C face of HPSI 4H-SiC.

Since the removal of oxides by molten KOH is the same process, the anisotropic molten-KOH etching of 4H-SiC is attributed to the anisotropic oxidation of the Si face and C face of 4H-SiC. First-principle calculations are then carried out to understand the anisotropic oxidation of the Si face and C face of 4H-SiC, as implemented in the Vienna ab initio simulation package (VASP). The projector-augmented wave (PAW) method is used to describe the electron-ion interactions , with the cut-off energy for the wave function expansion being 400 eV. The structural relaxations are carried out using the Perdew–Burke–Ernzerhof (PBE) exchange-correlation functional , until the total energy per cell and the force on each atom are converged to less than 1 × 10−8 eV and 0.01 eV/Å, respectively. Electronic structures and total energies are calculated by the screened hybrid density functional of Heyd, Scuseria, and Ernzerhof (HSE06) , with a 26% nonlocal Hartree−Fock exchange, to make the calculated bandgap energy of 4H-SiC consistent with the experimental bandgap energy of 4H-SiC.

At last, we discuss the molten-alkali etching mechanism of 4H-SiC, as well as the anisotropic etching of the Si face and C face. The molten-alkali etching of 4H-SiC is proceeded by cycling of the oxidation of 4H-SiC by the dissolved oxygen and the removal of oxides by molten alkali. The faster etching rate of the C face is caused by the fact that the oxides on the C face are unstable, and is easier to be removed with molten alkali, compared with what happens in the Si face of 4H-SiC. This gives rise to the fast and isotropous molten-alkali etching of the C face of 4H-SiC. For the Si face of 4H-SiC, the isotropous molten-alkali etching is slower than the preferential etching of strained atoms along the dislocation lines of dislocations, which results in the revelation of dislocations on the Si face of 4H-SiC.

4. Conclusion

In conclusion, we have revealed the anisotropic etching mechanism of the Si face and C face of 4H-SiC by experimental and first-principles investigations. It has been found that the molten-alkali etching rate of the C face is faster than that of Si face. And the activation energies for the molten-KOH etching of the C face is lower than that of the Si face of 4H-SiC. Combining XPS analysis and first-principles calculations, we conclude that the molten-alkali etching of 4H-SiC is proceeded by cycling of the oxidation of 4H-SiC by the dissolved oxygen and the removal of oxides by the molten alkali. The faster etching rate of the C face is caused by the fact that the oxides on the C face are unstable and are easier to remove with molten-alkali etching, rather than the C face being easier to oxidize.

上一篇: 现代碳化硅功率器件