Modern society has become increasingly reliant upon electrical appliances for comfort, transportation, and healthcare. This has motivated great advances in power generation, power distribution and power management technologies based on enhancements in the performance of power devices that regulate the flow of electricity. After the displacement of vacuum tubes by solid state devices in the 1950s, the industry relied upon silicon bipolar devices, such as bipolar power transistors and thyristors. Although the ratings of these devices grew rapidly to serve an ever broader system need, their fundamental limitations in terms of the cumbersome control and protection circuitry led to bulky and costly solutions. The advent of MOS technology for digital electronics enabled the creation of a new class of devices in the 1970s for power switching applications as well. These silicon power MOSFETs have found extensive use in high frequency applications with relatively low operating voltages (under 100 volts). The merger of MOS and bipolar physics enabled creation of yet another class of devices in the 1980s. The most successful innovation in this class of devices has been the Insulated Gate Bipolar Transistor (IGBT)1 . The high power density, simple interface, and ruggedness of the IGBT have made it the technology of choice for all medium and high power applications.

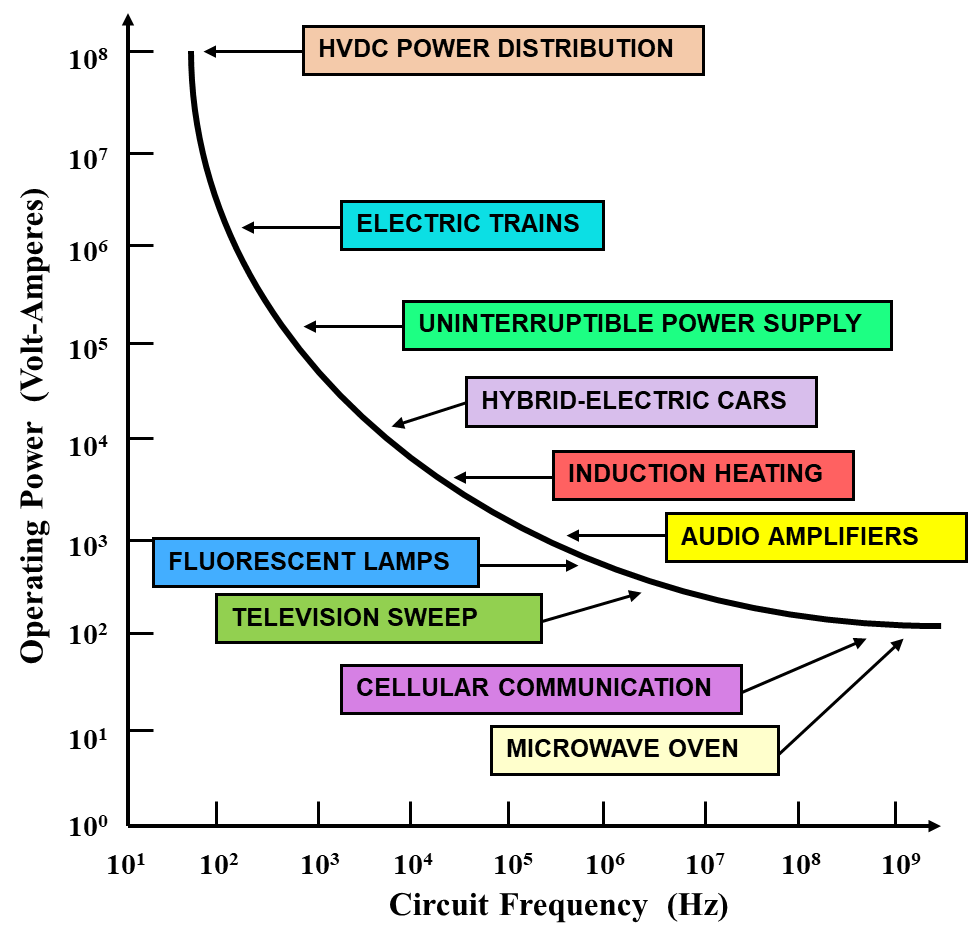

Power devices are required for systems that operate over a broad spectrum of power levels and frequencies. The applications for power devices are shown as a function of circuit operating frequency in Fig. 1.1. High power systems, such as HVDC power distribution and locomotive drives that require the control of megawatts of power, operate at relatively low frequencies. As the operating frequency increases, the power ratings decrease for the devices with typical microwave devices handling about 100 watts. Although all of these applications are served by mainly by silicon devices today, devices based on gallium nitride and silicon carbide are now being adopted. Until recently, thyristors were the only devices available with sufficient voltage and current ratings favored for the HVDC power distribution applications. The ratings of IGBTs have now grown to levels where they are now preferred to thyristors for voltage source converters and FACTs designs.

Fig. 1.1 Application spectrum for power devices.

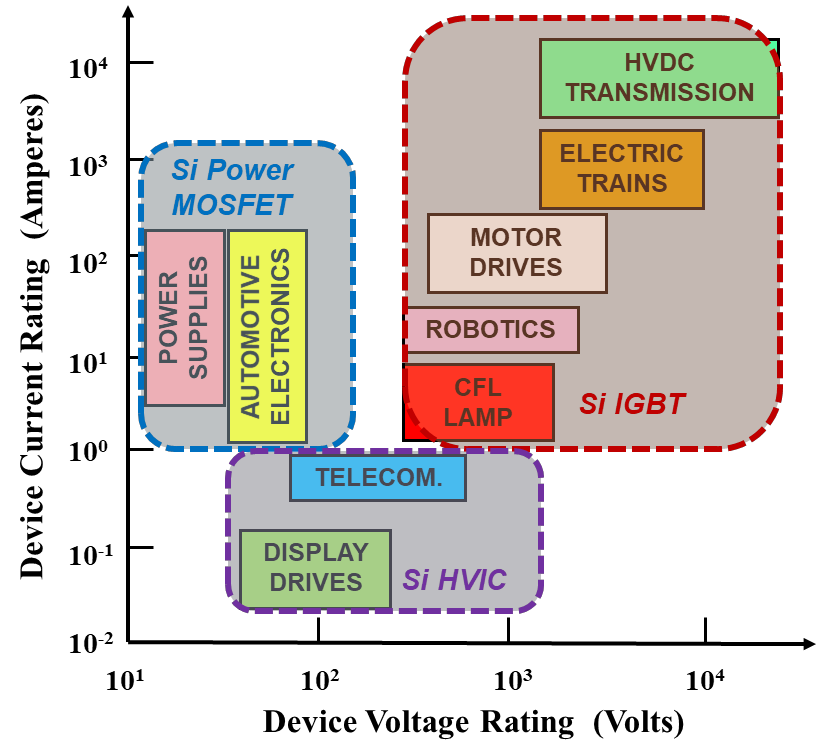

Another approach for classification of applications for power devices is based on their current and voltage handling requirements as shown in Fig. 1.2. On the high power end of the chart, silicon thyristors are available that can individually handle over 6000 volts and 2000 amperes enabling the control of over 10 megawatts of power by a single monolithic device. These devices are suitable for the HVDC power transmission and locomotive drive (traction) applications. During last 10 years, silicon IGBT modules have been developed with blocking voltages of up to 6500 volts and current handling capability above 1000 amperes. This has allowed the IGBT to increasingly replace thyristors in HVDC and traction applications.

Fig. 1.2 Ratings required for power devices for selected applications. The silicon technology appropriate for various applications is shown.

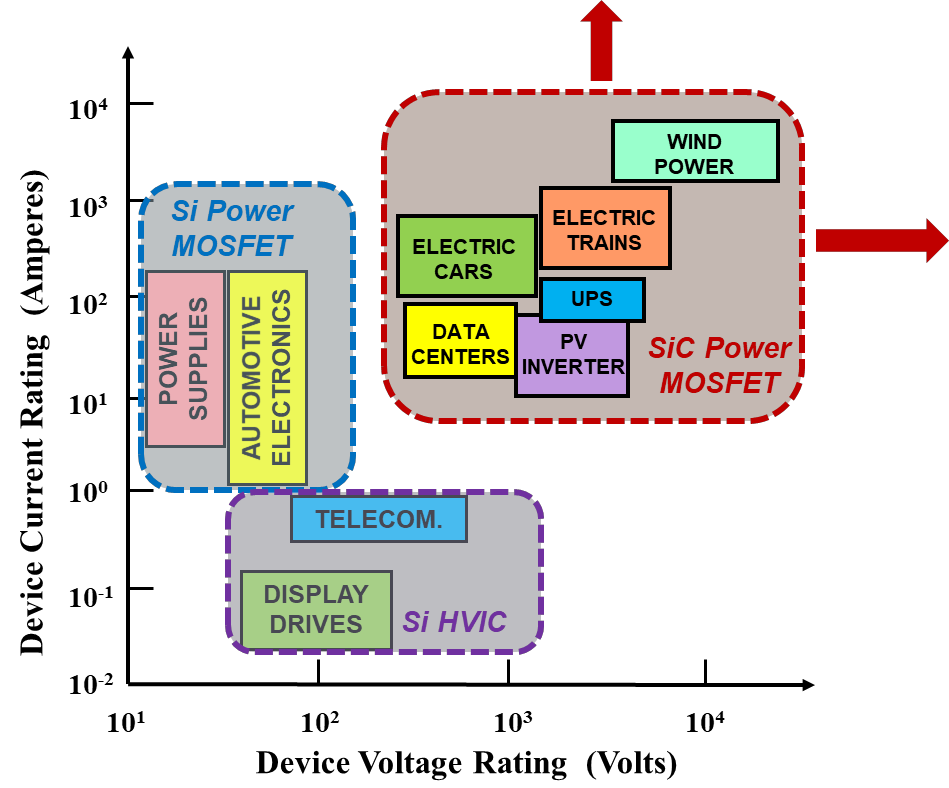

Silicon carbide power devices are being targeted towards the applications shown in Fig. 1.3. They have already been used in commercialized photovoltaic (PV) residential energy generators. Their major emerging market is for electric cars and trains.

Fig. 1.3 Ratings required for power devices for selected applications. The silicon carbide technology appropriate for various applications is shown.

Unipolar Power Rectifiers

Bipolar power devices operate with the injection of minority carriers during on-state current flow. These carriers must be removed when the switching the device from the on-state to the off-state. This is accomplished by either charge removal via the gate drive current or via the electron-hole recombination process. These processes introduce significant power losses that degrade the power management efficiency. It is therefore preferable to utilize unipolar current conduction in a power device.

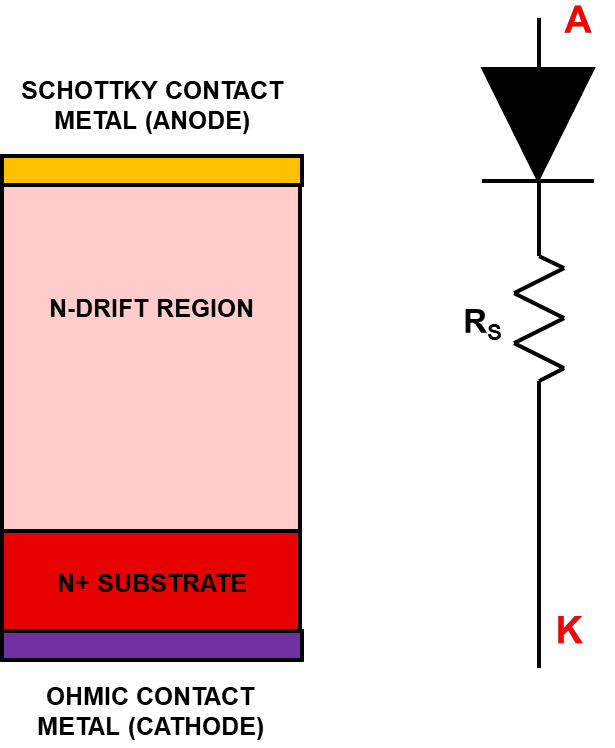

The commonly used unipolar power diode structure is the Schottky rectifier that utilizes a metal-semiconductor barrier to produce current rectification. The high voltage Schottky rectifier structure also contains a drift region, as show in Fig. 1.8, which is designed to support the reverse blocking voltage. The resistance of the drift region increases rapidly with increasing blocking voltage capability as discussed later in this book. Silicon Schottky rectifiers are commercially available with blocking voltages of up to 150 volts. Beyond this value, the on-state voltage drop of silicon Schottky rectifiers becomes too large for practical applications. Silicon P-i-N rectifiers are favored for designs with larger breakdown voltages due to their lower on-state voltage drop despite their slower switching properties. As shown later in the book, silicon carbide Schottky rectifiers have much lower drift region resistance enabling design of very high voltage devices with low on-state voltage drop. These devices are excellent replacements for silicon P-i-N rectifiers used as fly-back or free-wheeling diodes with IGBTs in inverters.

Fig. 1.8 Power Schottky rectifier structure and its equivalent circuit.

A major problem observed in Schottky rectifiers is the large increase in the reverse leakage current with increasing reverse bias voltage. An increase in reverse leakage current by more than one-order of magnitude occurs due to Schottky barrier lowering and pre-breakdown impact ionization in silicon devices2 . A much worse increase in leakage current by six orders of magnitude due to Schottky barrier lowering and tunneling is observed for silicon carbide and gallium nitride Schottky rectifiers. This is a serious problem for high temperature operation and stability for these rectifiers.

上一篇: 有机电化学晶体管的加工

下一篇: 4H- SiC的各向异性蚀刻机制