Abstract: The delivery of therapeutical molecules through the skin, particularly to its deeper layers, is impaired due to the stratum corneum layer, which acts as a barrier to foreign substances. Thus, for the past years, scientists have focused on the development of more efficient methods to deliver molecules to skin distinct layers. Microneedles, as a new class of biomedical devices, consist of an array of microscale needles. This particular biomedical device has been drawing attention due to its ability to breach the stratum corneum, forming micro-conduits to facilitate the passage of therapeutical molecules. The microneedle device has several advantages over conventional methods, such as better medication adherence, easiness, and painless self-administration. Moreover, it is possible to deliver the molecules swiftly or over time. Microneedles can vary in shape, size, and composition. The design process of a microneedle device must take into account several factors, like the location delivery, the material, and the manufacturing process. Microneedles have been used in a large number of fields from drug and vaccine application to cosmetics, therapy, diagnoses, tissue engineering, sample extraction, cancer research, and wound healing, among others.

Introduction

Skin is the largest organ in the human body. For several decades, it was only perceived as an “envelope” for the human body, aimed at separating the exterior from the interior. However, research has shown that the skin has multiple functions. Protection is one of them, but it is also involved in the immune system, thermal regulation, and even molecular synthesis. Skin can be used as a gateway for medical applications, for example, transdermal drug delivery, where the molecules released can be systemically absorbed into the bloodstream.

While the skin can act as a gateway for the absorption of therapeutic molecules, its effectiveness is hindered by the numerous layers it possesses. In a sense, this process goes against the very purpose of skin. Therefore, several strategies have been developed over the years to overcome this resistance.

A microneedle device is composed of an array of microneedles that can possess differ.ent properties depending on their application. For example, the length of microneedlesis related to their specific function and intended application. They can range from 100to 3000 um, with the most common size varying from 250 to 1500 um . Through theformation of micron-level pores on the skin's surface, microneedles enable the penetrationof macromolecular drugs into the stratum corneum in a minimally invasive manner, increasing penetration efficiency and facilitating the direct delivery of drug molecules to thedermis.

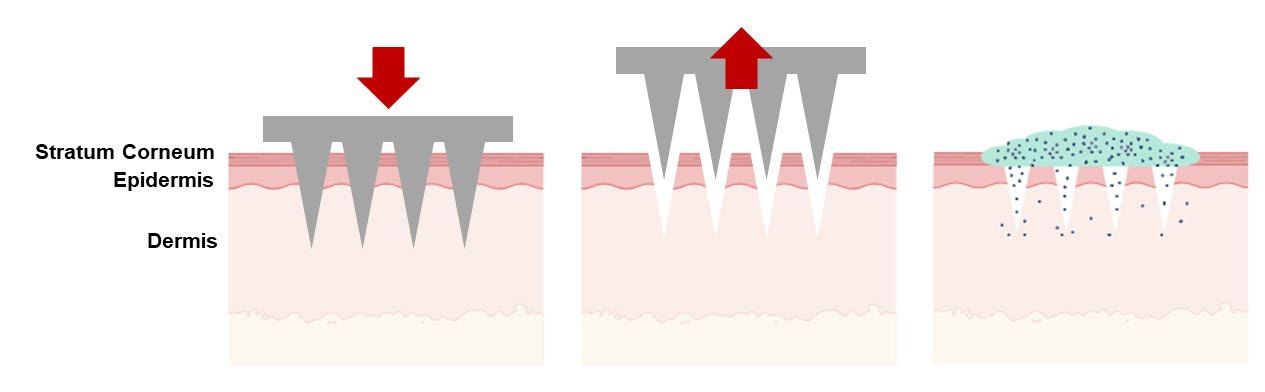

The solid microneedle system was the first one developed and is mainly composed by metals like nickel, palladium, stainless steel, gold, and titanium; silicon; and polymers. This type of microneedle is used for pre-treatment of skin. The needles are pressed into the skin, creating transitory micro-holes in the stratum corneum. Subsequently, drugs are applied into the microporated skin in the form of a topical pharmaceutical formulation (gel, spray, ointment, cream, lotion, foam, or patch), facilitating the drug diffusion across the formed channels, leading the molecules to the target tissue (Figure 2). To fulfil the demands of painless and minimally invasive application, the microneedle strength applied into the skin must be low, but enough to pierce the skin. They require good mechanical properties and formability to guarantee that it does not break or buckle in use . Given the ability to form fine incisions, solid microneedles can increase molecules’ permeability up to four times. Additionally, solid microneedles are easy to manufacture and can be utilized in the development of a coated microneedle system by applying drugs onto their surface. However, solid microneedles present some challenges. Firstly, they involve a two-step application process, which can be inconvenient for patients. Secondly, microporescreated by solid microneedles do not remain open for a long time due to the skin's naturahealing capacity, potentially limiting the window for drug delivery. On the otherhand, due to an occlusive condition, micropores may remain open for up to 3 days increasing the possibility of colonization by microorganisms under the patch, which canlead to a serious infection. Since solid microneedles consist of sharp pieces made ofnon-biodegradable material, there is a risk of them remaining inside the skin upon thedevice removal. Additionally, if highly viscous formulations need to be administratedthis system is not ideal, as the formulations may not flow smoothly into the formed poresresulting in a lack of precise control over the dosage. In summary, this system hasresiduals of sharp solid waste, poor biocompatibility, and an uncontmllable drug dosethus limiting its application in tissue regeneration .

Figure 2. Drug delivery prcess using solid microneedles. Red arrows indicate the movements direction.

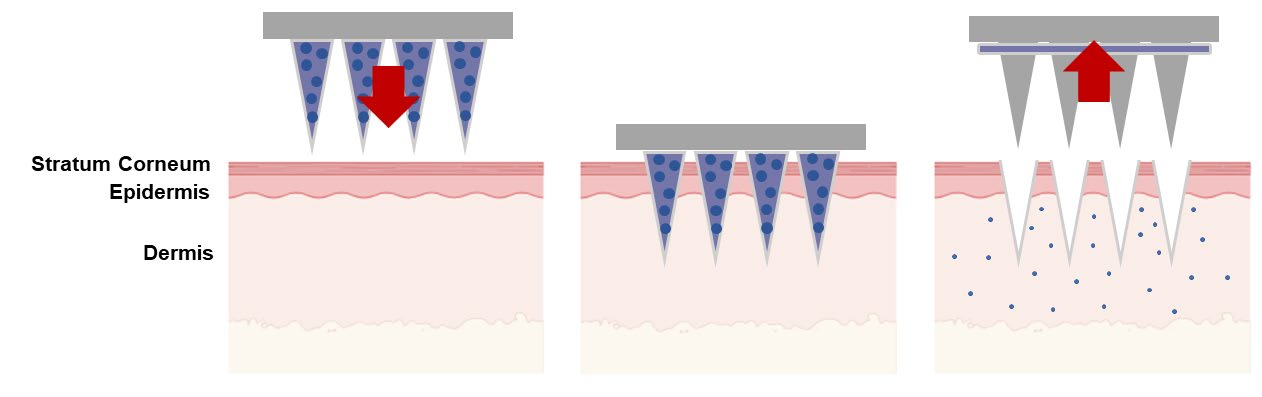

The manufacture of coated microneedles involves the preparation of either solid orhydrogel microneedles, followed by their coating with a drug solution or dispersion [83Upon the insertion of the coated microneedle system into the skin, the coated drug isreleased (Figure 3). Typically, the coating dissolves within a few minutes ofapplicationafter which the naked microneedles are removed from the skin,. The solid film usedas a coating generally comprises active compounds and water-soluble inactive excipientsThese excipients dissolve in the interstitial fluid, causing the coating to detach from themicroneedle surfaces. Various active compounds, such as small molecules, peptidesproteins, short nudeic acids, DNA, viruses, virus-like particles, polymer particles, andinsoluble inorganic particles, have already been coated onto microneedles. Coatedmicroneedles offer a single-stage application that does not require a drug reservoir. However, the drug loading capacity is limited to a maximum of 1 mg, with the amountof drug loaded depending on the coating method, microneedle size, and coating layerthickness.

Figure 3. Drug delivery process using coated microneedles. Red arrows indicate the movementsdirection.

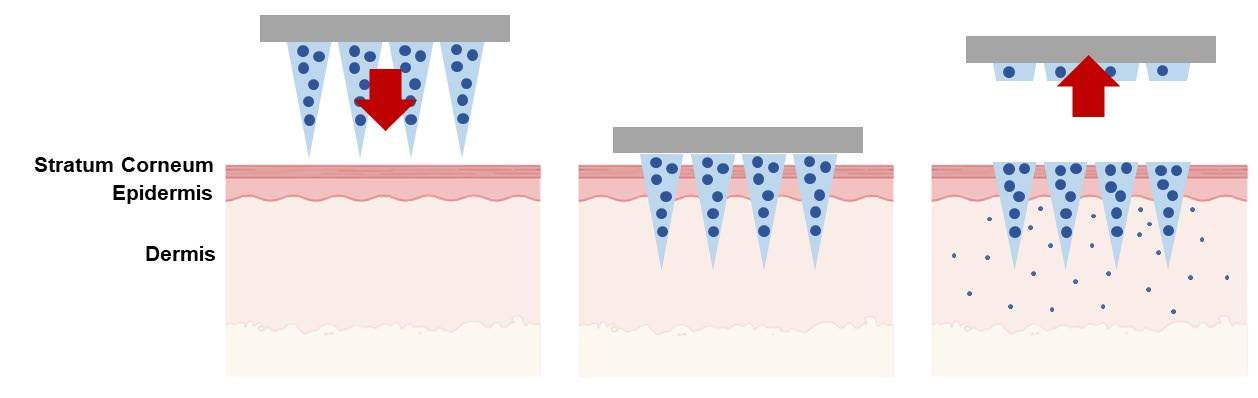

Dissolving microneedles are typically prepared from water-soluble sugars such as tre-halose or raffinose. They can also be prepared using biodegradable polymers like polyvinyl pyrrolidone (PVP) and polyvinyl alcohol (PVA). A common fabrication technique forthese microneedles is the solution-cast micromolding method, which utilizes a cavity prepared frm polydimethylsiloxane (PDMS) as a master mold. This type of microneedlecan disperse or encapsulate the drug within the needle body. During administrationthe dissolving microneedles are inserted into the skin and completely dissolve upon contactwith interstitial fluid, leading to the local release of the drug (Figure 4) .

Figure 4. Drug delivery process using dissolving microneedles. Red arrows indicate the movements direction.

Conclusions

The urgent need for a new and versatile technology that crosses the boundaries between invasive and non-invasive treatments has led to the emergence of microneedle systems, whose efficiency as a biomedical device has attracted enormous attention from the industry and academic research communities.

Over the past few years, there has been significant progress in the field of microneedles. This is not only in terms of microneedle compositions and morphologies, but also in the wide range of applications, including drug delivery, vaccinees, patients’ fluid collection (point-of-care diagnostics), and biosignal acquisition, among others.

Microneedles as innovative devices offer several advantages, such as effectiveness, portability, and precision. It is noteworthy that the material selection, microneedle design, and manufacturing process are key elements for the device success in any application.