Scandium aluminum nitride (ScAlN) has recently emerged as an attractive material for integrated photonics due to its favorable nonlinear optical properties and compatibility with CMOS fabrication. Despite the promising and versatile material properties, it is still an outstanding challenge to realize low-loss photonic circuits on thin-film ScAlN-oninsulator wafers. Here, we present a systematic study on the material quality of sputtered thin-film ScAlN produced in a CMOS-compatible 200 mm line, and an optimized fabrication process to yield 400 nm thick, fully etched waveguides. With surface polishing and annealing, we achieve micro-ring resonators with an intrinsic quality factor as high as 1.47×105 , corresponding to a propagation loss of 2.4 dB/cm. These results serve as a critical step towards developing future large-scale, low-loss photonic integrated circuits based on ScAlN.

I. INTRODUCTION

Photonic integrated circuits (PICs) hold great promise in realizing compact and scalable systems for a wide range of applications, from communications and computing to sensing and metrology . However, some of them demand functionalities beyond what traditional silicon photonics can offer, such as low-loss electro-optic or acoustic-optic modulation, broadband operation down to visible or ultraviolet (UV) wavelengths, and second-order parametric wavelength conversion. This has motivated the search for integrated photonics materials with more versatile properties.

Aluminum nitride (AlN) has emerged as an attractive candidate . As a material widely used in the Micro-ElectroMechanical Systems (MEMS) , AlN also shows the potential in areas such as optomechanicsand nonlinear optics. It has a wide bandgap of 6.2 eV, allowing operation from deep UV to mid-infrared (MIR). Already used as an insulator for microelectronic packaging, AlN is compatible with complementary metal-oxide semiconductor (CMOS) fabrication processes, making it a promising material for future foundry-level PIC manufacturing.

In this work, we present a systematic study on the fabrication of low-loss ScAlN PIC. We perform a detailed material study on sputter-deposited ScAlN films on 200 mm wafers and develop an optimized fabrication process to produce fully etched waveguides and ring resonators. We illustrate the effect of etching and annealing on the resonator quality factor (Q). By thermally healing the ScAlN thin film, we are able to reduce the absorption loss, achieving an average intrinsic Q over 1.00×105 (highest at 1.47×105 , corresponding to 2.4 dB/cm propagation loss). Our result paves a viable path towards the development of future low-loss, large-scale, and multifunctional ScAlN PICs.

II. METHODS AND RESULTS

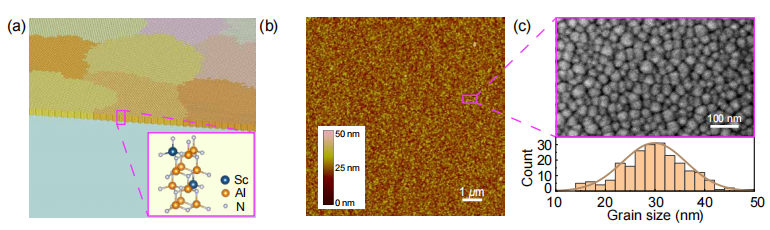

The ScAlN thin film is prepared by physical vapour deposition (PVD) on 200-mm Si wafers at the Institute of Microelectronics (IME). A sputtering target of nominal 10% Sc-doped aluminum is used to deposit 500 nm thick ScAlN films on 4 µm thermal oxide-on-silicon substrate. The ScAlN alloy inherits the lattice structure from either AlN or scandium nitride (ScN), depending on the Sc doping concentration. AlN exhibits a stable wurtzite structure (space group P63mc) with a six-fold in-plane rotation symmetry (point group C6v), and is polar along the c-axis. ScN has a nonpolar stable ground-state rock-salt phase (space group Fm¯3m, point group Oh). Theoretical density functional theory (DFT) of ScAlN predicts a stable wurtzite phase with Sc contents up to 56%, above which the rock salt phase is more favorable. The thin-film sample grown from a nominal 10% scandium doped target is hence expected to be in wurtzite phase. Fig. 1(a) shows an illustration of ScAlN thin film on thermal oxide. The honeycomb shape represents the hexagonal shape of the wurtzite structure, when being viewed along the c-axis. The film is polycrystalline with individual domains shown by different colors and orientations. The inset shows a wurtzite structure with the Al atoms being replaced by the Sc dopants. While doping flattens the wurtzite structure towards the layered hexagonal structure, the current ScAlN film is still expected to exhibit a wurtzite structure due to the relatively low doping concentration.

Fig. 1(b) presents an atomic force microscope (AFM) image of an as-grown film, showing a root-mean-square (RMS) surface roughness of 5.2 nm. Congregation of materials forms nanocolumns ranging from <100 nm to 300 nm, evidenced by the bright spots in the AFM image. This length scale is comparable to the photon wavelengths of 1550 nm, implying an additional source of scattering loss. A magnified image from a scanning electron microscope (SEM) in Fig. 1(c) reveals a granular surface with a mean grain size of 30 nm. This provides an avenue for charge trapping, defect creation and dangling bonds, which are all detrimental to film quality. The grain size distribution is shown in the lower part of Fig. 1(c). An energy-dispersive X-ray spectroscopy (EDX) is performed to identify the elemental composition (see Fig. 1(d)). The atomic percentage of the Sc dopants is calculated to be 11%, matching well with the nominal value of the sputtering target.

FIG. 1. Material characterization of ScAlN thin films. (a) Illustration of thin-film ScAlN with the c-axis perpendicular to the surface. The inset shows the lattice structure of ScAlN. (b) AFM image shows the rough surface after sputtering. The RMS surface roughness is 5.2 nm. (c) SEM image of the thin-film surface shows grain-like structure with a mean grain size of 30 nm. The bottom figure is the grain size distribution.

To assess the crystallinity and lattice structure information of the ScAlN sample, we compare it with a similarly sputtered undoped AlN thin film using X-ray diffraction (XRD) measurement (see Fig. 1(e)). Assignment of planes to peaks is based on the standard diffraction patterns of AlN from crystallographic data base. The X-ray wavelength from the synchrotron source is calibrated to be 0.154 nm with the substrate silicon (004) peak at 2θ = 69.09◦ . The AlN data shows that it is single-phase with the c-axis perpendicular to the film surface. The AlN(0002) and AlN(0004) peaks at 35.96◦ and 76.24◦ correspond to higher order diffractions (n = 2, 4), and the lattice parameter is calculated to be 0.4989 nm, agree ing well with the literature value of 0.4980 nm. The slight down-shift of the ScAlN(0002) and ScAlN(0004) peaks at 35.84◦ and 75.96◦ correspond to a slightly larger lattice parameter of 0.5005 nm, indicating a small expansion of lattice due to the larger ionic radius of Sc3+ than that of Al3+. An additional peak at 32.96◦ is assigned to the first-order diffraction from the m plane (10-10). The corresponding lattice parameter is 0.2715 nm and the lattice constant is 0.3135 nm, slightly larger than the literature value of 0.3110 nm. This is again attributed to the larger ionic radius of Sc3+. The presence of the m plane peak together with the dominant c plane peaks indicates that some parts of the film has the c-axis pointing in-plane, likely due to non-uniformity in the ScAlN film. The rocking curve measurements of the (0002) peaks (Fig. 1(e) inset) show a full-width at half-maximum (FWHM) of 1.8◦ for both doped and non-doped films. This value is consistent with other sputter-deposited AlN films in the literature, but larger than those grown using epitaxial growth methods, whose rocking curve FWHM is as small as 0.004.

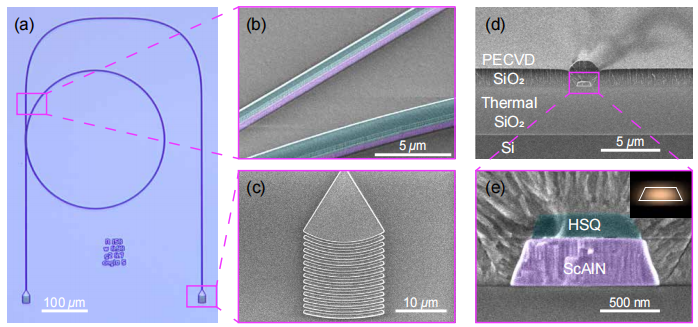

Fig. 2(a) shows an optical microscope image of a typical ring resonator. Fig. 2(b) is an SEM image of the waveguide, showing a smooth side wall without re-deposition. Fig. 2(c) shows the grating coupler, designed to match 8◦ single-mode fiber array for TE mode coupling at 1550 nm. The waveguide cross-section is shown in Fig. 2(d). Fig. 2(e) is a magnified SEM of the waveguide cross-section (ScAlN marked purple, and unremoved HSQ marked cyan), showing a sidewall angle of 70◦ . We noticed some vertical strata in the ScAlN waveguide, which may suggest the existence of nanocolumns in the film. The inset shows a simulated fundamental TE mode, which is well confined inside the waveguide.

FIG. 2. ScAlN waveguides and ring resonators. (a) Optical microscope image of a typical ring resonator. The ring resonator is pulley-coupled to the bus waveguide. Light in the waveguide is coupled to single-mode fibers using grating couplers. (b) SEM image of ring-bus coupling region. The ScAlN waveguides are false-colored in purple and the HSQ resist is in cyan. (c) SEM image of the grating coupler. (d) SEM image of the waveguide cross-section. A 1.7 µm-thick PECVD oxide layer is deposited as a cladding. (e) Magnified view of the waveguide cross-section. Inset shows the simulated fundamental TE mode.

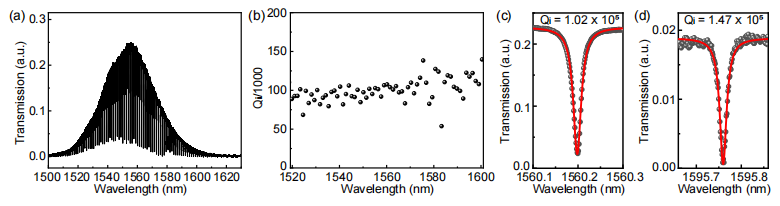

Fig. 3(a) shows a measured transmission spectrum of the ring resonator from 1500 nm to 1630 nm. The extinction ratio is close to 20 dB for most of the resonances, indicating that the resonator is close to critical coupling. Several groups of modes are observed. By extracting the group indices from the free spectral ranges (FSR), we identify three families of TE modes. Via fitting, we obtain an average intrinsic Q of the fundamental TE mode (TE0) of 1.00 × 105 . Fig. 3(b) is the intrinsic Q distribution of the TE0 mode over the whole grating coupler pass band. The intrinsic Q for the higher-order TE modes (TE1, TE2) are around 0.60×105 . This is because the higher order modes tend to experience larger interface scattering. Fig. 3(c) is a typical resonance near 1550 nm with an intrinsic Q of 1.02×105 . A maximum intrinsic Q of 1.47×105 is found in a similar device at longer wavelength (Fig. 3(d)). This corresponds to a propagation loss of 2.4 dB/cm.

FIG. 3. Transmission measurement and Q factor extraction. (a) Transmission spectrum of a ring resonator with grating couplers. Multiple TE modes are observed. The fundamental TE mode is nearly critically coupled. (b) The average intrinsic Q factors of the fundamental TE mode is around Q = 1.00 × 105 . (c) A typical resonance with Q = 1.02 × 105 . (d) A resonance with an intrinsic Q = 1.47 × 105 is obtained in a similar device.

IV. CONCLUSION

In summary, we have demonstrated the fabrication of lowloss waveguides and ring resonators on PVD-grown thin-film ScAlN. The highest measured intrinsic Q is 1.47 × 105 , corresponding to a propagation loss of 2.4 dB/cm. A dry etching recipe based on chlorine chemistry is developed to achieve a fully etched structure with a smooth, redeposition-free sidewall. We identified an optimal annealing temperature of 400 ◦C for reducing the waveguide loss. Our results serve as an important step towards future large-scale photonic integrated circuits on thin-film ScAlN. Currently, the dominant loss is still from material imperfections, which may be improved through further optimizations in deposition processes to achieve better crystallinity and homogeneity. Future developments of functional devices beyond linear components, such as electro-optic modulators, acousto-optic modulators, and various nonlinear optical devices, are the immediate next steps to unlock the full potential of this material platform.

上一篇: 异质蓝宝石支撑的低损耗光子平台

下一篇: 碳纳米管集成电路技术路线图及技术挑战