A life-cycle assessment (LCA)is based on the attention given to the environmental pro-tection and concerning the possible impact while producing, making, and consuming pro-ducts. It includes all environmental concerns and the potential impact of a product's life cy.cle from raw material procurement, manufacturing, usage, and disposal (that is, from cradleto grave). This study assesses the environmental impact of the ultra pure water process olsemiconductor manufacturing by a life-cyele assessment in order to point out the heavy envi.ronmental impact process for industry when attempting a balanced point between productionand environmental protection. The main purpose of this research is studying the developmentand application of this technology by setting the ultra pure water of semiconductor manu-facturing as a target. We evaluate the environmental impact of the Precoat filter process andthe Cation/Anion (C/A) filter process of an ultra pure water manufacturing process, The dif-.ference is filter material used produces different water quality and waste material, and has asignificant, different environmental influence. Finally,we calculate the cost by engineeringeconomics so as to analyze deeply the minimized environmental impact and suitable processthat can be accepted by industry. The structure of this study is mainly combined with alife-cycle assessment by implementing analysis software, using SimaPro as a tool. We clearlyunderstand the environmental impact of ultra pure water of semiconductor used and providea promotion alternative to the heavy environmental impact items by calculating the environ-mental impact during a life cycle. At the same time, we specify the cost of reducing theenvironmental impact by a life-cycle cost analysis.

In recent years global environmental protection problems have been brought to everyone'sattention, such as climate changes, acid rain, and ozone layer depletion, The Organization forInternational Standards (ISO) has listed a life-cycle assessment through the ISO 14000 seriesof standards-ISO 14040-ever since 1993.It has also announced relevant successive standards since 1998, which can be used as an effective tool and method for assessing the envi.ronmental impact of a business evaluation or to improve a product's design, manufacturing.usage, or disposal, This offers a global enterprise a clear common rule to adjust to thegrowing environmental awareness. The semiconductor manufacturing industry is a hi-tech in-dustry consisting of electrical machinery, physics, optics, material, and machinery and man-agement science. The competitiveness of electronic industrial products is alfected by thetechnical development of semiconductors. The semiconductor component process uses manykinds of sour and lkali solutions, organic solvents, and special gases, These original. supplies not only maybe dangerous to staffmembers, but may create a heavy pollution ofwastewater, waste gis, and toxic materials. The pollution characteristics even become morcand more complicated with the level of products, If a firm does not conduct pollution pre.vention work early on, then it will consume more money for disposal treatment and maycause a serious problem of environmental pollution in the future.

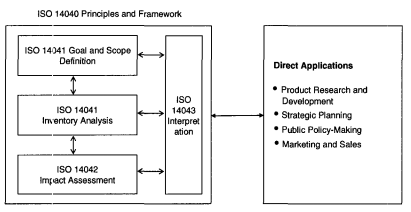

Ever since August 1990,the U.S. Society of Environmental Toxicology and Chemistry (SETAC) has offered a series of seminars and training courses on life-cycle assessment technology, which has contributed to the completion of its well-recognized framework of relatedtechnical tools. SETAC has thus become the worldwide authority of LCA application techni-cal tools and methods. The ISO 14040 environmental management - life-cycle assessment-principles and framework (ISO/TC-207/SC5,1997)was officially published in 1997, propos-ing an integrated andconceptualframeworkand direction of life-cyele assessmenttechnology. The ISO 14041 environmental management- life-cycle assessment - goal andscope definition and inventory analysis(ISO/TC-207/SC5,1998)was published in 1998.clearly stating that the goal and scope definition are the first essential job of life-cycleassessment. This means that we must first clarify the goals and reasons for a life-cycle as sessment as well as the end user or target audience of the life-cycle assessment results.Such a way prevents aimless life-cycle assessments, and thus the type and the depth of da-ta needed by an assessment can be determined correctly (Ding, 1997). Appraisers must ac-knowledge that life-cycle assessment research is an iterative process, meaning that as thedata and information collected increase, the pre-determined research scope may change inorder to satisfy the initial research objectives.One thing worth cautioning is that thelife-cycle assessment is a highly data-intensive assessment approach. The various data col-lected during the course of research must be evaluated by a logical, formal, and repetitivcmethod to ensure the reliability of researcresults(Xu,1996a/1996b). Lu(1996a/1996b)pointed out that life-cycle inventory analysis can be divided into six stages: raw material pro.curement, manufacturing and assembly, distribution and transportation, use/reuse/maintenance.recycling,and disposal handling.

Based on the above, the cause-effect relations, logic processes, and functional applicationsof life-cycle assessment technology are summarized in Figure 1. To date, many research or-ganizations and experts and scholars have given somewhat different definitions to life-cycleassessment. The U.S, SETAC (Society of Environmental Toxicology, 1991/1993) believes thatlife-cycle assessment is a tool that can be used to measure the environmental burdens result-ing from manufacturing or human activities. Vigon et al. (1993) defined life-cycle assessmentas an evaluation of the environmental impact incurred during the entire course from cradleto grave, meaning from the starting point of raw material procurement to the ending pointof disposal to the earth for products, Lai(1997), the domestic life-cycle assessment expert, stated that a life-cycle assessment in essence uses scientific methods to investigate activities.products, and services systematically, assess and quantify the energies and resources used andthe various emissions and pollutions produced during their life cycle (that is, from cradle tograve)so as to derive an environmental impact and arive at conclusions that can be usedas reference points for future improvement opportunities and items. According to Yang(1997), the concept of a product life cycle integrates the environmental impact at differentstages of raw material exploration, manufacturing, product use and disposal, ete. from upstream to downstrearn and assesses the degree of impact that a product life cycle has on theenvironment.

Fig1

The life-cycle cost analysis (LCCA)is an economic technology to determine the total operating (or using)facility expense during a period (Tim et al., 1999). The National Instituteof Standards and Technology define LCCA as a total discount cost of operating (or using),maintaining, construction(or facility)handling, and construction(or facility) owning. LCCAis avery important design method to control the initial and future cost of constructionowning. There are three variables in the LCC equation: holding related cost, happening costduring a period,and using a discount rate discounting the future cost to current cost (Timet al..1999).

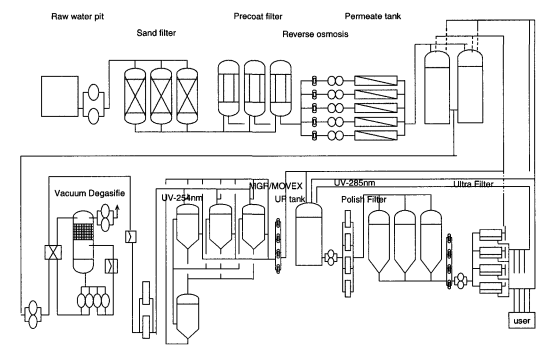

The Precoat filter process is a traditional process of the ultra pure water manufacturingprocess,The production flow chart is shown as Figure 2. The functional unit is raw watervolume which can be calculated by producing 10,000 wafers, One needs 3.3m' of raw waterto produce a wafer, We can calculate the total raw water needed as 44,840.7lm'when pro-ducing a functional unit by calculating the reverse process.

Fig2

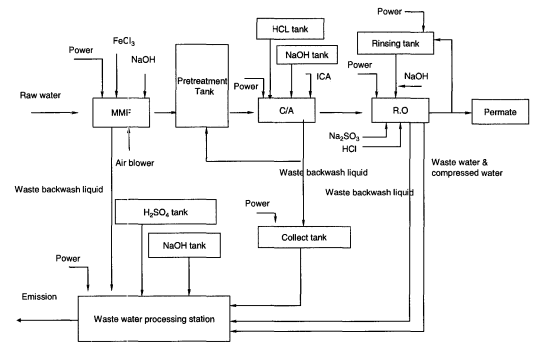

The manufacturing flow chart of the C/A filter process is shown as Figure 3. This is thepopular application in the current semiconductor industry. The water by this process can promote the effectiveness and the life cycle - for example, WCF of the R.O. process can goto 90% and above. It is better than the Precoat filter process which is 75%. The changefrequency of the R.O. membrane can be for three years, longer than the two years generallyprovided by the Precoat filter process (see Table 6).

Fig3

The output ofthe backwashis 21,060Kg,combined by3,987.36Kg for NaOH and17,072.64Kg for FeCl;. The consumptive materials’description and change frequency of theC/A filter process are shown in Table 6 for the material life cycle. We assume that the ma-terial consumption is 50% in the MM filter, and then the functional unit consumption of an-thracite is 0.0475m’(3.56m'x50%x[234hrs/(365daysx24hrs)]},sand is 0.036m’{2.7m'x50% x[234hrs/(365daysx24hrs)]},and gravel is 0.015m’{1.12m'x50%x[234hrs/(365daysx24 hrs)]}To sum up all of it above, we show the MM filter manufacturing subsystem in Table 8, theC/A filter manufacturing subsystem in Table 9, and the R.Ã. filter manufacturing subsystemin Table 10.

This study adopted SimaPro which is LCA software to provide several impact evaluationmodels such as:Ecopoints 1990(CH),Ecopoints 1997(CH), SimaPro 1.1 (CML), SimaPro2.0(CML),SimaPro 3,Eco-Indicator 95,SimaPro 4 Eco-Indicator 99(C), SimaPro 4 Eco.Indicator 99 (H), SimaPro 4 Eco-Indicator 99 (l). The software analyzes the LCA of the ultrapure water manufacturing process bySimaPro 3and Eco-Indicator 95 and can analyzeAssembly perspective, Life-Cycle perspective, Disposal Scenario perspective, Disassembly perspective, and Reuse perspective. After establishing the inventory database, SimaPro analyzesthe environmental impact by characterization, normalization, evaluation, and indicator to find outwhich is the worst cne.The “Compare Function" then compares the environmental impactbetween the Precoat filter process and the C/A filter process. We first compare the environmentalimpact of the individual subsystem process for them before integrating a process comparison.

The environmental impact of the sand filter process (0.927 Pt)is worse than the MM fil.ter process (0.635 Pt). For only on the “Carcinogen" item, the environmental impact of theMM filter process is worse than the sand fiter process. All evaluation items of the environ-mental impact of the C/A filter process(18.9 Pt)is worse than the Precoat filter process(0.0235 Pt); and the difference between them is very big. The environmental impact of theR.0. filter process in the Precoat filter process (0.0922 Pt)is worse than in the C/A filtcrprocess (0.0777 Pt). In view of all ultra pure water manufacturing processes, the environ-mental impact of the C/A filter process is worse than the Precoat filter process, but only in the“Ozone”" item, There is a very big difference in environmental impact between the Pre.coat filter process(1.02 Pt)and the C/A filter process(19.6 Pt).

上一篇: 工业系统中超纯水细菌污染分析