Abstract

In Micro Electro-Mechanical Systems (MEMS) manufacturing, high aspect ratio (HAR) features are essential. Liquid treatments, such as cleaning or wet etch of these features presents a challenge in device fabrication where the removal of residue and/or oxide inside the structures is critical. Conventional methods have proven inadequate for getting chemical to reach the bottom of such structures. This paper examines the use of a vacuum priming wet immersion method to introduce liquid chemicals or rinse water throughout the entire HAR feature prior to the oxide etching step, and vacuum drying for successful removal of all liquids from these features.

Problem statement

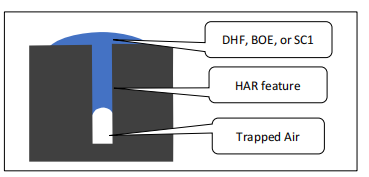

High aspect ratio features are an integral part in MEMS processing. In some cases, with 3D integration, through silicon vias (TSV) may reach 110:1 aspect ratio [1-2]. However, even for more common cases of ≥30:1 aspect ratio, the ability of wet chemicals to reach the bottom of these structures becomes challenging, and in case of structures with hydrophobic sidewalls, almost impossible [3]. As a result, the residues or contaminants remaining in these features can affect the following steps as well as the final device performance [4-7]. In the structures approaching aspect ratio of 30:1 and beyond, the physical dynamics within the trenches/vias become too great to overcome. With the increase of depth, larger amount of air may be trapped at the bottom preventing the liquid penetration [8]. The difficulty with getting liquids to penetrate high aspect ratio features is a result of several factors: the surface tension of the liquid, pressure of the approaching liquid and the gas pressure of the trapped air [9] (see Fig. 1). The surface tension of the liquid is a physical characteristic of the chemistry, such as DHF, BOE, SC1. Changes of the surface tension of these chemicals may require introduction of surfactants, which could affect these chemicals performances. Furthermore, simply reducing the surface tension through the use of surfactants still may not allow the liquid to overcome the gas pressure of the trapped air below .

Figure 1: Illustration of the air trapped by the liquid in high aspect ratio structure

To overcome this phenomenon, the air within the system needs to be removed so it does not become trapped DHF, BOE, or SC1 Trapped Air HAR featurebeneath the liquid surface. Once the successful fill with above-mentioned chemicals is achieved, the additional challenge is to completely dry the high aspect ratio structures. The evaporation of liquid from these structures is more difficult since the water vapor must escape from restricted areas. These restricted, high aspect ratio features present a situation where drying is much more difficult .

C2MI offered solution

To address priming and drying of the high aspect ratio features in MEMS manufacturing, specifically designed modules were installed within an Akrion GAMA w

et processing bench. These modules (see Fig. 2) can reach a vacuum as low as 7 Torr. The priming/drying process is completely automated and process parameters are adjustable through recipes.

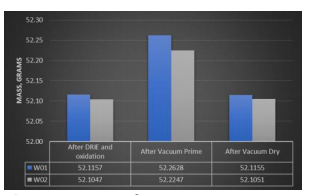

Figure 4: Test wafers mass measurements after vacuum priming and drying.

上一篇: 满足先进半导体器件工艺要求的颗粒清洗技术

下一篇: 亚微米接触孔清洗面临的挑战