ABSTRACT

Chemical systems containing oxidants are widely used at various stages in semiconductor processing, particularly for wet cleaning and polishing applications. This dissertation presents a series of studies related to oxidative removal of materials in the Front-End-Of-Line (FEOL) and Chemical Mechanical Planarization (CMP) processes during IC fabrication.

In the first part of this study, stripping of photoresists exposed to high dose of ions (1E16 As/cm2 ) was investigated in activated hydrogen peroxide systems. Stripping of photoresists (PR) exposed to high dose (>1E15/cm2 ) ion beams is one of the most challenging steps in FEOL processing. This is due to unreactive crust layer that forms on the resist surface during ion implantation. The use of hydrogen peroxide systems activated by metal ion or UV light, for disrupting crust formed on deep UV resist to enable complete removal of crust as well as underlying photoresist was investigated. A systematic evaluation of variables such as hydrogen peroxide and metal ion concentration, UV intensity, temperature and time was conducted and an optimal formulation capable of attacking the crust was developed. A two step process involving pretreatment with activated hydrogen peroxide solution, followed by treatment with sulfuric acid-hydrogen peroxide mixture (SPM) was developed for complete removal of crusted resist films.

In the second part of this study, electrochemically enhanced abrasive removal of Ta/TaN films was investigated in solutions containing 2,5 dihydroxy benzene sulfonic acid (DBSA) and potassium iodate (KIO3). This method known as Electrically-assisted Chemical Mechanical Planarization (ECMP) is generating a lot of interest in IC manufacturing. Ta/TaN films wereabraded at low pressures (<0.5 psi) on a polyurethane pad under galvanostatic conditions. The effect of variables including pH, KIO3 concentration, and current density has been explored. In the optimized formulation, tantalum and tantalum nitride removal rates of ~170 A0 /min and ~200 A0 /min, respectively have been obtained at a current density of 1 mA/cm2 . The use of benzotriazole as a copper inhibitor was required to obtain Ta to Cu selectivity of 0.8:1. Additionally, the nature of the oxide film formed on tantalum during the electrochemical abrasion process was characterized.

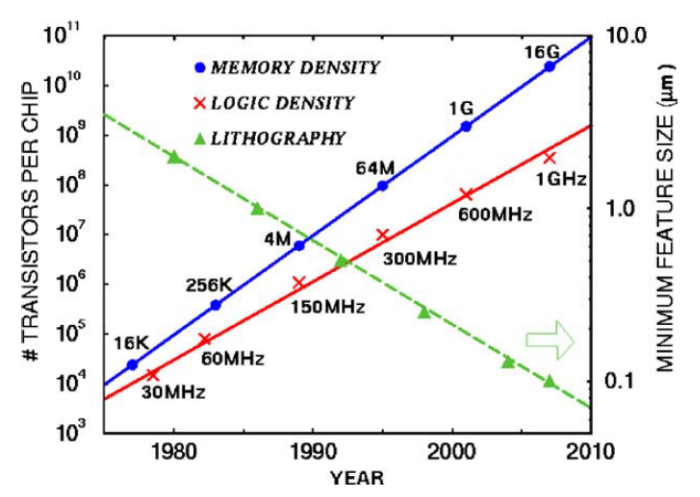

Figure 1. Trends in logic and memory devices

上一篇: 亚微米接触孔清洗面临的挑战

下一篇: MEMS 微细加工中的真空辅助湿法加工