Abstract

Shrunkenintegrateddevicepatterningformanufacturing requires surface cleanliness and surface smoothness inwet chemical processing [l]. It is necessary to control all processparameters perfectly especially for the common cleaning techniqueRCA clean (SC-1 and SC-2) [2]. In this paper the characteristic andeffect of surface preparation parameters are discussed. The propertiesof RCA wet chemical processing in silicon technology is based onprocessing time, temperature, concentration and megasonic power ofSC-1 and ODR.An improvement of wafer surface preparation bythe enhanced variables of the wet cleaning chemical processisproposed.

I.INTRODUCTION

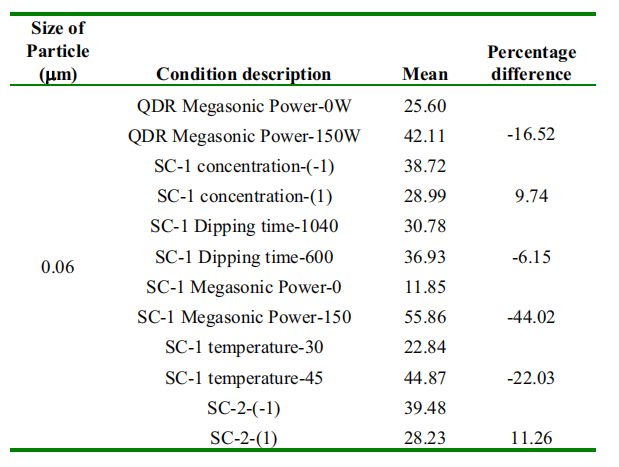

HE SC-1 (APM) and SC-2 (HPM) standard clean or RCA, as published in Kern in 1970 have been the primarymeans of removing particles [2]. In order to optimize thecleaning recipe to meet the cleanliness requirements ofadvanced CMOS device with the available chemicals, thedetails of the APM and HPM chemistries are beingreevaluated. To this end, the effects of processing time.temperature, concentrations and megasonic power of SC-land ODR are extensively studied. These studies have shownthat the largest main effect for particle removal efficiency ismegasonic power, followed by temperature and concentrationwith small effect from SC-2. A statistically designedexperiment (DOE) was conducted in a wet bench processor.This paper is going to propose a wafer surface preparationRCA recipe having optimal particle removal efficiency, basedon proper megasonic power for SC-l and ODR and SC-ltemperature. Further, each result will be discussed in detail.

II.EXPERIMENT

A screening DOE (Design of Experiment) is used todetermine the main effect of particle removal efficiency. Thefollowing factors were varied:

·SC-l processing time (600s, 1040s)

·SC-l concentration (1:1:5,1:4:20 ofNH4OH:H202:H20 composition)

·SC-I temperature (30 & 45 C)

·SC-1 Megasonic power (0 & 150 Watt)

·QDR Megasonic power (0 & 150 Watt)

·With and without SC-2 process.

A total of 16 runs were made and the run order asgiven in TABLE 1 and TABLE 2 was randomized. Allprocesses were conducted in a fully automatic DNS wetstation on 200mm, cz, p-type, 7-1092 wafers from SEH. Thechemical tanks are recirculated and filtered. The SC-1 andODR bath are equipped with megasonic.

The wafers are intentionally pre contaminated byprocessing the wafers in HF bath and in a resist tool type withspin to dry dryer. HF will change the wafer surface tohydrophobic, which repels water, and easily attract particles.Typical contamination is varied from 100 - 2000 particleswith particle threshold at 0.13 and 0.16 um. As PRE isstrongly dependent on initial counts and on the initialconditioning of wafers (cleaning before contamination), thewafers are randomly selected for each DOE condition [3]. Allexperiment on contaminated wafers was carried out onsamples from the same batch.

Three wafers are used for slot 1, 25 and 50 withdummy oxide coated and etched wafers slotted in between tosimulate the actual production condition andprovidechallenging contamination level because dummy waferscontained etch by-products that could transfer to bare Siwafers. Pre and post scan data are taken using SP1l, a laserbased particle counter to detect the particle levels. The SPlproduces a haze map. Haze is the low frequency signal causedby the scattering of laser light during darkfield inspection andcan reflect minute variations in surface uniformity orroughness that are caused by wafer processing [4]. The datawill be further analyzed with variability graphs using JMPsoftware to determine the significant factor in particle removalefficiency.

III. RESULT

PRE% depends strongly on megasonic power, particularlywith SC-1 chemistry for both 0.06um and 0.13um particle sizeas refer to TABLE 1 and TABLE 2. Earlier reports havetheorized that the chemical reaction between ammoniumhydroxide, hydrogen peroxide and water undercuts surfaceparticles while the vibration energy released by the megasonicunit librates the particles by overcoming the weak butattractive Van Der Waals forces holding them to the substrate[5]. With additional megasonic power, it is believed that theacoustic pressure buildup from the pulsed megasonicfrequencies used with the result of random fluid motion or micro streaming enhance the particle removal efficiency [6]The acoustic pressure from the megasonic power is a vitalvariable in wet chemical processing as the PRE% is high evenwithout the help of SC-1 chemical. It is recommended to makeuse of megasonic power in both SC-l and ODR baths forstages with no pattern broken concern, which is before polyline is formed.

上一篇: 300mm直径硅片湿洗槽出水口设计

下一篇: 半导体封装基板材料技术趋势