This article discusses the recent advances in polishing of advanced materials. Ninety-fifive journal articles published in 2005–2007 are brieflfly introduced. The topics are advances in chemical mechanical polishing (CMP), flfluids for polishing, modeling of polishing, polishing of brittle materials, robotic polishing, polishing with vibrations or beams, and friction in polishing processes. CMP is perhaps the hottest research topic in the articles reviewed. Many “noncontact” processes are developed using magnetic flfluids, electrorheological flfluids, and abrasive flflow for polishing of complicated geometries or diffificult-to-approach regions. Modeling of polishing processes helps to understand the polishing mechanisms and is thus increasingly performed worldwide. More research on simulations of polishing processes can be expected in the near future. Polishing of brittle materials is also highly demanded. Automatic polishing of curved surfaces using robots and CNC machines, and polishing with vibrations and beams are promising. Investigations of friction in polishing processes help to understand the polishing mechanisms or control the polishing processes. Keywords Abrasive flflow machining; Advanced materials; Beams; Brittle materials; Chemical mechanical polishing; Curved surfaces; Electrorheological flfluid; Friction; Magnetic flfluid; Modeling; Polishing mechanisms; Polishing processes; Robotic polishing; Simulation; Vibrationassisted polishing.

2. Chemical mechanical polishing (cmp) With the demand for higher-performance in integrated circuits (ICs) and MEMS devices, there is more research on CMP. Besides planarization of Si wafers, CMP is also increasingly performed to planarize and/or smooth variousthin fifilms, low-k and ultra-low-k devices, copper structures, polymer substrates, hard disk substrates, SiC wafers, etc. Research efforts are also made to understand the CMP mechanisms and the effects of slurry and abrasive types, pH values, temperature changes, polishing pads, polishing time, and other process parameters on material removal rates (MRRs), surface quality, and within-wafer nonuniformity. The pH value of slurry is an important factor in CMP processes. Planarity strongly depends on the pH value [15]. Slurries with the highest removal rate have a high dissolution rate at lower pH [16]. The tantalum oxide fifilms formed during CMP are thinner at pH 2 compared to pH 10 [17]. The pH value change caused by the temperature change affects the surface state of abrasive particles [18]. The pH adjustment and addition of sodium dodecyl sulfate result in a ten-fold increase in selectivity compared to conventional colloidal silica slurry [19]. With an increased temperature, the pH value decreases [20]. Oxalic and malonic acids are most effective at pH 3–4 for abrasive-free removal of Cu [21].

CMP of copper structures is an important operation, and therefore the effects of various parameters during copper CMP have been studied [22, 23]. The use of Scanning Kelvin Probe Force Microscopy can characterize post-CMP copper structures and detect metallic contamination [24]. The polishing pad can signifificantly affect the process stability. The holes on the pad surface is fifilled by the reactant, and the pad surface gradually has hard glazing, which reduces the pad ability of absorbing slurry and leads to scratches on the workpiece. The pad must be conditioned regularly [25]. Plowing is the major mechanism if dressing is conducted by a diamond face, while cutting action dominates if dressing is performed by a diamond point [26]. The surface roughness of the pad determines the MRR as the material is removed by direct contact with the pad surface [27]. The surface waviness with a concentric circular

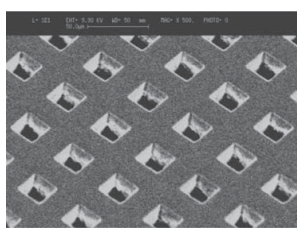

Figure 1.—25–25 m square pattern on SU-8 after chemical mechanical polishing [31].

pattern is generated on highly-boron-doped Si wafers by CMP with amine system slurry [28]. The waviness results from the change of the etching rate in the amine etching system. If CMP of the Si substrate is performed using a hard polishing pad, a smooth surface can be obtained without waviness. Studies of peeling with respect to the number of ultra low-k dielectric fifilms in interconnect stacking during CMP [29] reveal that delamination during polishing depends on the elastic properties of the interconnect stack. The addition of ultra low-k levels has a major effect on delamination during CMP, due to the effect of the stack residual stress and elasticity. Polymers are replacing silicon as the major substrates in microflfluidic system fabrication because of their outstanding features. CMP is well suited for polishing SU-8 structures (Fig. 1). Polished poly(methyl methacrylate) (Fig. 2), polycarbonate, and SU-8 surfaces have nanometer-order surface roughness [30, 31], acceptable for most MEMS applications. Studies of CMP of Si and SiC wafers show that the removal rate and surface quality vary greatly with crystal orientations [32]. High-quality surfaces can be obtained by CMP with colloidal silica [33]. Lapping of SiC wafers causes great residual stresses and a deep damage layer.

上一篇: 碳化硅与锗合金的电学特性