Abstract

We present work on the impact of surface contamination before phosphorus diffusion on solar cells and life-time samples. Metal surface contamination on KOH / IPA textured Cz wafers was measured by the Sandwich-Etch ICPMS technique. High surface contamination, especially of Cu, was found directly after texturing, which is attributed to low solubility of metals in diluted, non-oxidizing alkaline solution. Different contamination levels were reached by applying standard cleaning procedures such as HCl / HF dip sequences and the piranha etch. The emitter profiles that were tested ranged from heavy diffusions of 45 Ω/sq to shallow diffusions of 120 Ω/sq. It was found that threshold values which obviously impact life-times and solar cell performance (Voc) were much higher than expected.

Introduction

Metal surface contamination is well-known to play an important role in semi-conductor processing. [1] However, no studies on threshold values for surface contamination on silicon surfaces before standard industrial high temperature processes for solar cell processing, such as diffusion and surface passivation exist. To find limiting concentrations on solar cell performance the influence of surface metal contamination on the diffusion process was investigated.

![]()

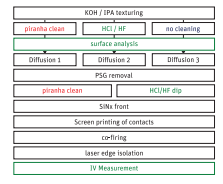

Fig. 1. Cleaning sequence used in both experiments (DI water dips in between every step). Groups were separated at 1., 2., and 3. HCl-Dip: 3 %, 5 min; HF-Dip: 2 %, 2 min; Piranha clean: H2SO4 (98 %) / H2O2 (30 %) 6:1, 10 min @ 80°C.

High surface concentrations were obtained right after texturing. HCl / HF dips and piranha clean were used to reduce these concentrations. The surface concentrations of the different groups were measured using the Sandwich-Etch ICP-MS technique. [3] Two experiments were carried out (Fig. 2 (a) and (b)). In the first experiment the influence of the different cleaning procedures on symmetrical life-time samples and standard screen-printed solar cells was measured. Three differently cleaned groups of KOH / IPA textured p-type 1,6 Ωcm Cz wafers were diffused in three consecutive 65 Ω/sq diffusions in a diffusion tube furnace. To ensure comparability of the three diffusions the wafers were placed in the same boat positions, and wafers for sheet resistance measurements were placed at the beginning, in the middle, and at the end of each batch. The PSG was removed in a batch process using 2 % HF. The cleaning step after PSG etching was applied to remove potential back-contamination from the PSG etching (HCl / HF), and to etch back (piranha clean) the emitter. The etch-back was thought to be necessary to remove – at least parts of – the potentially metal-rich dead layer, and therefore, to distinguish between surface effects and the effect of contamination in the emitter region. In addition to the solar cells, life-time samples were prepared similar to Experiment 2.

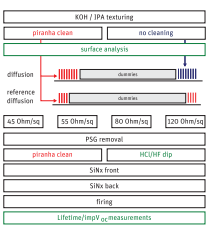

Fig. 2. (a) Process flow of Experiment 1; (b) process flow of Experiment 2

In Experiment 2 the influence of high metal surface concentration on four different diffusion profiles (45, 55, 80 and 120 Ω/sq) was compared. For this purpose symmetrical life-time samples (SiNx – n+ – ptype base – n+ – SiNx) from 0,8 Ωcm KOH / IPA textured wafers were prepared. For each emitter group a reference diffusion with cleaned wafers at the two ends of the diffusion boat (Fig. 2 (b)) was followed by a test diffusion with cleaned reference wafers also at the gas inlet and non-cleaned samples at the gas outlet in order to avoid potential cross contamination. Again the PSG was removed and the HCl / HF and piranha clean were applied.

3. Results

3.1. Surface concentrations High metals surface concentrations were measured right after the KOH / IPA texturing (Fig. 3). The high concentrations are attributed to the low solubility of most metals in diluted KOH [2]. We assumed that most of the contamination resulting from the wire sawing process precipitates on the surface of the wafer during the etching process. Highest concentrations are found for Cu ranging from 7E13 – 2E14 atoms/cm2 . Fe, Ca and Al are also found in relatively high concentrations in the range of 1E12 atoms/cm2 . Comparing the two experiments it can be stated that concentrations differ by a factor of five in the case of Cu and by a factor of about two for the other elements with the higher concentrations in Experiment 1. Al differs widely between samples and experiments – a fact that has been observed in previous experiments and cannot be explained so far. After the HCl / HF clean, surface concentrations have been reduced significantly, by a factor of 60 for Cu and 50 for Fe. The other elements are also reduced, yet much less drastically. Most of them are still well over the detection limit of 1E10 atoms/cm2 . After the piranha cleaning sequence almost all elements in both experiments are reduced to 1 – 12E10 atoms/cm2 . Many elements, such as Cr, Ti, and Mn are reduced to less than the detection limit of 1E10 atoms/cm2 .

上一篇: 晶圆键合的基本问题

下一篇: 实现新的硅表面处理标准的湿法清洁方法