1. Introduction

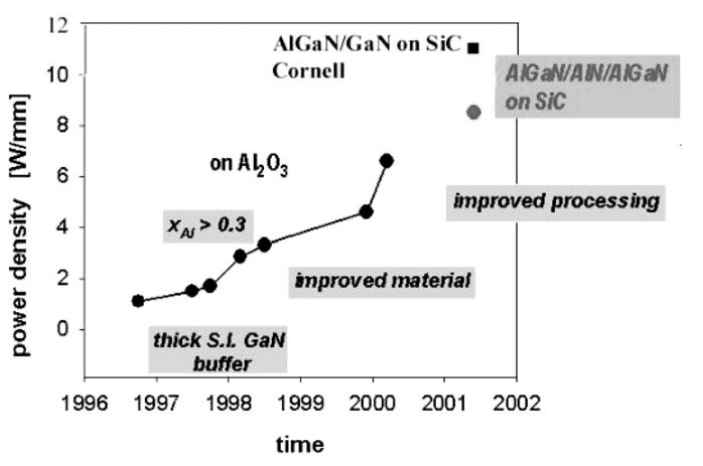

The gallium nitride materials system has established itself as extremely important for next generation opto-electronics by fifilling the void in the opto-electronic spectrum from the green to the ultra-violet. This has created new markets in green LED traffific signals, full colour outdoor displays and promises the next great advance in lighting since the flfluorescent lamp. The promise of electronic applications is primarily in the area of sources and amplififiers for communications and low loss switches in power conditioning applications. (Al, Ga, In)N based semiconductors promise both to add on to present silicon, GaAs and InP basedsolid-state solutions for power amplififiers and to be a major component of a new power electronics technology. As members of the III–V nitride family, AlN, GaN, InN and their alloys are all wide bandgap materials, and can crystallize in both zinc blende and wurtzite polytypes. In cubic form, GaN and InN have direct bandgaps, while AlN is indirect. Wurtzite (Al, Ga, In)N forms a continuous and direct band gap alloy from 1.9 eV (InN) to 6.2 eV (AlN). GaN itself possesses a large band gap of 3.4 eV, a very high breakdown fifield (3 × 106 V cm−1) and an extremely high peak (3 × 107 cm s−1) and saturation velocity (1.5 × 107 cm s−1) [1]. These properties in combination with the high band offset and the high electron mobility observed in AlGaN/GaN heterostructures (2019 cm2 V−1 s−1) [2], promise an excellent microwave power performance of GaN based heterojunction fifield effect transistors. Furthermore, the wurtzite crystal structure of group-III nitrides is highly piezoelectric, offering device design possibilities not accessible with common GaAs and InP based semiconductors. Due to the strong chemical bonds in the semiconductor crystal, GaN based devices are also promising for high temperature operation and applications under radiation exposure. Historically, GaN was one of the fifirst III–V-compound semiconductors to be studied. First reports on the epitaxy of GaN by halide vapour phase epitaxy date back to the year 1969 [3]. Due to the non-availability of a single crystalline GaN substrate, GaN fifilms were typically deposited on sapphire substrates. Although years of intensive studies on GaN growth and its properties followed, the interest declined in the early 1980s, as several severe problems, preventing the utilization of GaN in electronic and opto-electronic devices, seemed to be impossible to overcome: the GaN fifilms suffered from a very high n-type background carrier concentration and no p-type doping could be achieved. In the late 1980s high quality GaN fifilms on sapphire substrates were reported in a two-step growth process, which resulted in a dramatic improvement of both the structural and the electrical properties of the GaN fifilms [4]. In 1989, p-type GaN was obtained by post-growth LEEBI treatment of magnesium doped GaN fifilms [5]. Three years later the LEEBI procedure was replaced by a post-growth thermal treatment [6]. The persistent work on group III nitrides, especially in Japan, resulted in an interest revival in nitride semiconductors all over the world. A broad range of GaN electronic devices has been realized, including high electron mobility transistors (HEMTs), heterojunction bipolar transistors (HBTs), bipolar junction transistors (BJTs), Schottky and pin rectififiers and metal oxide semiconductor fifield effect transistors (MOSFETs). First, we present the progress in the AlGaN/(AlN)/GaN HEMT performance from a historic point of view and discuss critical issues involved in the process. Second, (Al)GaN bipolar transistor performance and related issues are addressed..

background carrier concentration in the GaN fifilms had to be reduced. In the past, the n-type conductivity of GaN layers had been mainly attributed to the formation of nitrogen vacancies in the crystal. More detailed investigations, though, suggested that oxygen impurities, rather than nitrogen vacancies, are the major source of residual electrons [11, 12]. Oxygen, if incorporated on the nitrogen site is a shallow donor in GaN. Water and oxygen are omnipresent impurities in the system. Both can either be present as impurities in the metal–organic precursors and gases or enter the system through leaks in the MOCVD system or during wafer loading. Another potential source is the sapphire substrate, since water forms during the sapphire (Al2O3) pretreatment in hydrogen. The inflfluence of the wafer loading procedure and the sapphire pre-treatment on the residual background carrier concentration was investigated [13], and it was found that both contribute to the residual background carrier concentration in the fifilms. By using ex situ baked sapphire substrates and inserting a long flflush time after wafer loading, the residual carrier concentrationin 3.2 µm GaN fifilms could be reduced from ns = 1.3 × 1013 cm−2 to ns = 7.2 × 1012 cm−2, which is equivalent to an average volume carrier concentration of n = 2.2 × 1016 cm−3. The carrier concentration in the near surface region of the wafer was n = 1×1016 cm−3, determined by C–V measurements using a mercury probe. Besides system purity, the residual background carrier concentration depends on the growth conditions of the high temperature GaN layer. Generally, highly resistive fifilms were obtained at reduced growth temperatures and/or reduced reactor pressures, characterized by a higher carbon impurity concentration in the fifilms [14]. Under these conditions, the background donors were compensated by a deep acceptor, the so-called yellow level, appearing as a broad band in the photoluminescence (PL) spectrum at a wavelength of approximately 550 nm. Possibly, carbon impurities assist in the formation of gallium vacancies, which had been identifified as source of the yellow luminescence [15]. For the fabrication of S.I. GaN base layers a two-step process was chosen: the fifirst part of the layer was deposited at low pressure to compensate for the higher concentration of oxygen donors close to the sapphire/GaN interface by a higher concentration of deep acceptors; the second part of the layer was deposited at atmospheric pressure to ensure a low density of point defects in the GaN layer close to the AlGaN/GaN interface. At the early stage of the AlGaN growth development, the AlGaN layers were typically deposited at a reduced reactor pressure of 76 Torr to suppress the pre-reactions between TMAl and NH3, with a high NH3 flflow rate of 6 slm. Under such growth conditions step flflow growth of AlGaN similar to GaN was observed for xAl < 0.25. Films with higher Al mole fraction exhibited a grainlike structure (fifigure 2(c)).

上一篇: 衬底对氮化钛薄膜APCVD生长的影响

下一篇: 等离子喷涂PVD