Atomically resolved scanning tunneling microscopy observations are performed on hydrogen-terminated Si(110) surfaces after wet cleaning. When a Si(110) wafer is dipped into dilute HF-containing solution, the surface is constructed by piling small terraces and steps. When the sample is consequently rinsed with ultrapure water, some characteristic features such as a zig–zag chain inside a terrace, a single row at step edges and an isolated zig–zag chain on a terrace are clearly observed, and their atomic arrangements are determined. Excessive rinsing, however, creates the ridge-shaped structure of nanometer height, which is explained by anisotropic etching by OH− ions in water.

For the fabrication of ultralarge-scale integration (ULSI) devices in the next generation, the further miniaturization of complementary metal-oxide-semiconductor (CMOS) circuits is essential. One of the candidates to realize this requirement is to change substrates to form CMOS circuits from familiar Si(001) wafers to Si(110). 1 It has been predicted that a Si(110) wafer is a promising substrate for semiconductor devices, because the hole mobility of Si(110) with a radical oxidation method2 has already been achieved to be 2.4 times higher than that of Si(001). 3 And there has been renewal of interest in adopting Si(110) substrates for ULSI devices. In order to realize CMOS circuits with higher performance than those today, it is necessary to flflatten the interface between the gate insulators and Si(110) substrates, because the interface roughness determines the carrier mobility of metaloxide-semiconductor (MOS) transistors.4 For this purpose, a wet cleaning procedure to terminate the Si(110) surface with H atoms and flflatten it on the atomic scale is required before the formation of gate insulators. Numerous attempts have been made to investigate the inflfluence of various wet cleaning processes on the surface structure of either Si(111) or Si(001) on the atomic scale.5–7 However, little attention has been given to Si(110) surfaces. Jakob et al. has reported the surface structure of Si(110) with infrared absorption spectra after a chemical treatment with NH4F solution.

They have predicted the local binding geometry of the surface. However, infrared absorption measurements solely reveal average structural information of the surface. Ye et al. and Wang et al. have analyzed the electrochemical etching of Si(110) surfaces on the atomic level by scanning tunneling microscopy (STM) (Ref. 9) and infrared spectroscopy,10 respectively. They have insisted that electrode [Si(110) sample and STM probe] potentials are important experimental parameters in determining the surface morphology in electrochemical etching. Hence the electrochemical process should not be generally compared with the wet cleaning used in the semiconductor industry. The purpose of this study is to clarify the atomic structure of hydrogen-terminated Si(110) surfaces after dipping into dilute HF-containing solution, that is, primal cleaning of silicon wafers, and subsequent rinsing with ultrapure water. A guideline to obtain an atomically flflat hydrogen terminated Si(110) surface is presented.

In the present study, all the samples were n-type Si(110), and their resistivities were 10 V cm. After sacrifificed oxides were formed, each sample was dipped into a solution of H2SO4 s 97 wt. %d : H2O2 s 30 wt. %d =4:1 (by volume) for 10 min and then rinsed with ultrapure water for 10 min. Then each sample was dipped into a solution of HFs 50 wt. %d :H2O2 s 30 wt. %d : H2O=1:1:98 (by volume) for 3 min in order to remove the sacrifificed oxide and terminate the surface with H atoms (Sample A). Some samples were subsequently rinsed with ultrapure water for 10 min (Sample B) or 60 min (Sample C). Total organic carbon contents in ultrapure water were suppressed to 0.42 ppb, and the resistivity of water was more than 18.2 MV cm at 23 °C. Hence organic carbon residual and metallic contamination were avoided on the Si(110) surface during wet cleaning. It was confifirmed by either the hydrophobicity of the surface or Fourier transform infrared spectrometry (FTIR) measurements that every sample surface was hydrogenterminated. Within 15 min of the wet cleaning process, the Si samples were introduced into ultrahigh vacuum (UHV) chambers. Experiments were performed with a commercial UHV STM system (JEOL JSTM-4500 XT). Pt–Ir tips were cleaned by electron bombardment before imaging. During STM measurements, a background pressure of 3.5 3 10−8 Pa was achieved with neither thermal treatment nor baking. STM observations were performed under a tunneling condition of 0.3 nA at a sample bias of −2.0 V.

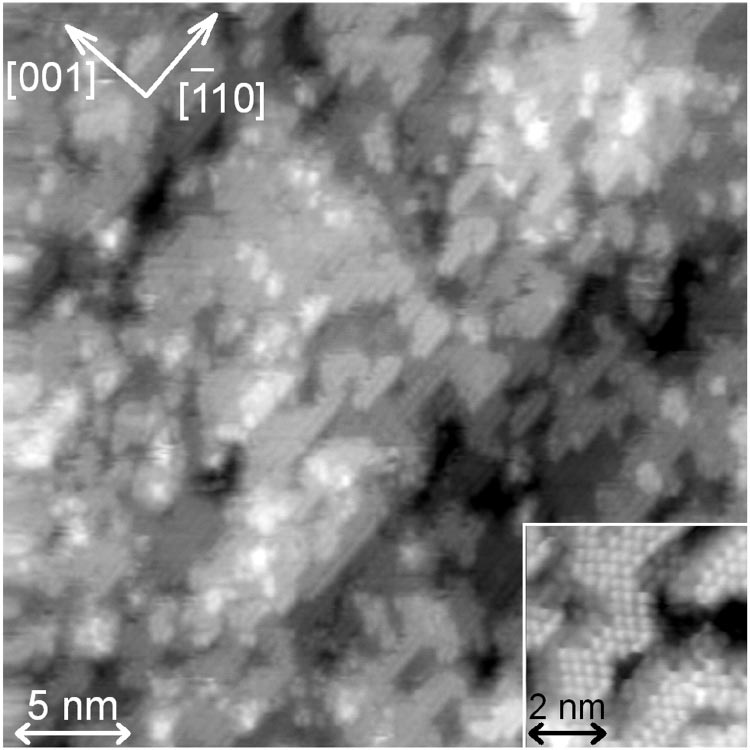

Figure 1 shows a typical STM image of the surface after dipping into dilute HF-containing solution (Sample A). The scanned area is 343 34 nm2 . The maximum height of irregularities s Rpvd and root-mean-square roughness s Rrmsd in Fig. 1 are 1.21 nm and 0.16 nm, respectively. It is obvious that the surface is constructed by piling terraces and steps. However, each terrace is very small and has many atomic-scale holes and protrusions. Furthermore, step edges run along various directions such as f 1 ¯10g and [001]. A magnifified image is shown in the inset of Fig. 1 in which the scanned area is 5.53 5.5 nm2 . Atomic-scale dots forming a terrace are clearly resolved in the magnifified image, and the distance between dots along the f 1 ¯10g direction is measured to be 0.38 nm. The step height is measured to be about 0.19 nm. Furthermore, neighboring atomic rows along the f 1 ¯10g direction form a zig–zag chain. It seems reasonable to suppose that the zig–zag chains represent an ideal Si(110) 13 1 terrace terminated by monohydrides along the f 1 ¯10g direction.8,9 HF-containing solution removed monohydrides not only at the both ends of the chain but also inside the chain. As a result, small terraces with step edges along various directions are formed.

Fig 1

Figure 2 shows a STM image of a 343 34 nm2 area of the Si(110) sample after cleaning in dilute HF-containing solution and subsequent rinsing with ultrapure water for 10 min (Sample B). RPV and Rrms are 1.07 nm and 0.12 nm, respectively. Although the scanned area in Fig. 2 is the same as that in Fig. 1, the surface structure completely changes by the rinsing process. Namely, the nanometer-scale terraces shown in Fig. 1 disappear and wide terraces spread along the f 1 ¯10g direction. Most step edges run along the f 1 ¯10g direction, and the step height is measured to be about 0.19 nm. It is well known that OH− ions in water can etch silicon surfaces.5–7 It is likely that surface atoms at highly reactive sites in Fig. 1 were removed preferentially during the short period of rinsing with ultrapure water to form the surface structure shown in Fig. 2. A magnifified image of the surface (Sample B) is shown in Fig. 3 in which the scanned area is 7.03 7.0 nm2 . Atomic images forming terraces and steps are clearly observed.

上一篇: 晶体硅结构的选择性湿蚀刻工艺优化

下一篇: 湿法蚀刻MEMS硅腔的工艺控制