INTRODUCTION

The need of isopropyl alcohol (IPA) for wafer drying hasbeen increasing in the semiconductor industry, because thestructure of semiconductor devices is gettingmorecomplicated and IPA drying is more preferable to avoidpattern disruption of complicated device structure. Also, asthe feature size of the semiconductor devices continuouslydecreasing, the cleanliness level of IPA needs to be furtherimproved. Filtration is an indispensable technology tocontrol the cleanliness, and more and more filters with finerremoval rating are now being used to achieve the requiredcleanliness level.

Filter's removal rating is determined by particle removaefficiency (PRE) under a standard condition, which istypically room temperature (RT) water [l]. In generalhowever, the actual PRE varies depending on the chemicaland temperature to be used. Therefore, understanding thePRE in the actual chemicals is important as well asselecting an appropriate removal rating for effective usageof filters. For this reason, we have developed PREevaluationmethods in several chemicals which arecommonly used in the semiconductor manufacturingprocesses [2~6]. Regarding PRE in IPA, we evaluated Pall10-nm-ratedsurface-modifiedpolytetrafluoroethylene(SM-PTFE) membrane filter using three kinds of testparticles with their size around 10 nm at RT, and found thatthe filter shows sufficiently high PRE in the chemical. Onthe other hand, IPA is often used at elevated temperaturewhen used in the actual processes. Therefore, in this studywe developed a method that can evaluate PRE in hightemperature IPA in order to investigate the influence oftemperature on filters PRE. The test method was applied toevaluate two kinds of Pall SM-PTFE filters with eachdifferent removal rating, and the difference in actual PREbetween the filters in RT and high temperature IPA wasdiscussed.

EXPERIMENTAL

Particle size distribution measurement in IPA (before and after heating) The heating temperature of IPA was decided to be 70 C. In the actual manufacturing process, the temperature of IPA varies with each user’s condition. However, since the boiling point of IPA is 82 C, temperature of 70 °C or lower is adopted in most cases.

For filter's PRE evaluation, we need to choose test particleto be challenged to test filters. In the previous PREevaluation in RT IPA [6], we used the following three kindswithof test particles: Platinum particlecoveredpolyethylenimine (Pt PEI), zirconia particle (ZrO), andgold particle covered with polyvinylpyrrolidone (Au PVP)These particles have each different charged state; Pt PEI ispositively charged, Au pVp is negatively charged, andZrO2 is nearly neutral. Jin-Goo Park et al. [7] conductedzeta potential measurement of silica and silicon particles inwater and water/IPA mixture, and reported that zetapotential of the particles approached neutral values as theconcentration ofIPA reached 50 volume%. In view of thesefacts, we assumed that ZrO2, silica, and silicon particleshave similar charged stated in 100% IPA. Since silica andsilicon particles are presumed to be ones of actualcontaminants during wafer cleaning process, we decided tofocus on the test using ZrO2 that shows similar behaviorwith silica and silicon particles.

For filter's PRE evaluation, we need to choose test particleto be challenged to test filters. In the previous PREevaluation in RT IPA (6], we used the following three kindsof test particles:Platinum particle covered withpolyethylenimine (Pt PEI), zirconia particle (ZrO2), andgold particle covered with polyvinylpyrrolidone (Au PVP)These particles have each different charged state, Pt PEl ispositively charged, Au PVp is negatively charged, andZrO2 is nearly neutral. Jin-Goo Park et al. [7] conductedzeta potential measurement of silica and silicon particles inwater and water/IPA mixture, and reported that zetapotential of the particles approached neutral values as theconcentration ofIPA reached 50 volume. In view of thesefacts, we assumed that ZrO2, silica, and silicon particleshave similar charged stated in 100% IPA. Since silica andsilicon particles are presumed to be ones of actualcontaminants during wafer cleaning process, we decided tofocus on the test using ZrO2 that shows similar behaviorwith silica and silicon particles.

Previously, the particle size distribution in IPA wasmeasured by means of dynamic light scattering (DLSZetasizer* Nano ZS, Malvern*) at RT. In this time, theparticle needs to be dispersed in 70 °C PA as well. In orderto confirm the fact, the ZrO2 added to IPA (the suspendingsolution) in a PFA bottle was heated up to 70 °C and keptfor 20 minutes; then, the solution was cooled down to RTand measured by DLS. We have assumed that if the particleis dispersed at RT after heating, it was dispersed during theheating as well. Another solution without heating was alsoprepared and measured for comparison. Although themeasurement tool (DLS) is capable of measuring theparticle size at 70 °C, we adopted the procedure describedabove, because measurement at high temperature needs toconsider the temperature dependence of other parameterssuch as refractive index of the ZrO2 and IPA, which makesdirect data comparison between at RT and at hightemperature somewhat difficult.

Particle challenge test of filters in RT and 70 oC IPA

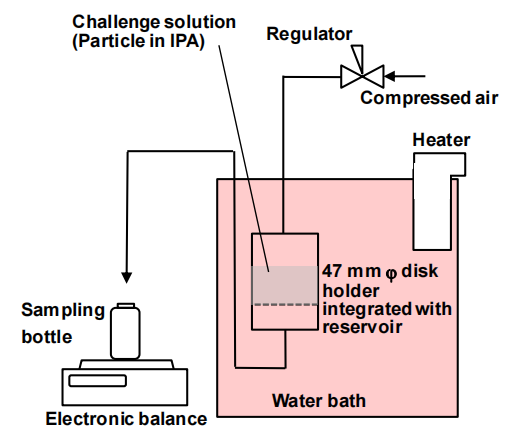

In order to evaluate PRE in RT and 70 C IPA, particle challenge tests of filters were performed using the test system shown in Figure 1. First, the test particle (ZrO2) was added to electronic grade IPA to make suspending solution and it was poured in the reservoir (i.e. at the upstream of the disk holder). For the test in 70 C IPA, the reservoir was placed in the water bath at 70 C for 10 minutes to stabilize the designated temperature. For the test in RT IPA, the same filtration system was employed except for not using the water bath. Next, the suspending solution (influent) was filtered by each filter at the flow rate of 5 ml/min., and the effluent was collected in a sampling bottle. Finally, the zirconium (Zr) concentration in the influent (= C0) and the effluent (= C) was quantified with ICP-MS (7700s, Agilent) to calculate PRE (= [1-C/C0] × 100).

Test filters were Pall 10-nm-rated and 5-nm-rated SM-PTFE membranes, both of which are filters used in the leading-edge semiconductor device manufacturing processes. Table 1 summarizes the overall conditions of this evaluation. Test was repeated five times. Note that the test condition No.1 in the table 1 is the same condition as in the previous study [6].

Fig 1

As shown in Figure 2, the ZrO2 particle used for the challenge test showed almost no change in the size distribution even after heating up to 70 oC in IPA, and thus the particle in 70 oC IPA was presumed to be dispersed same as in RT IPA. These data ensure that we can directly compare the PRE at RT and 700C in IPA.

上一篇: 去除晶圆表面颗粒的方法