Introduction

Megasonic cleans have been applied to remove defects such as particles and polymer/resist residues in silicon wafer fabrication of IC devices. However, with the shrink of device technology node, megasonic cleans are being challenged to maintain high cleaning efficiency promoted by streaming force of stable cavitation for the smaller particles without producing pattern collapse caused by violent implosions of transient cavities [1]. S. Kumari et al. reported that CO2-dissolved water (CO2 DIW) was potentially able to suppress wafer damage during megasonic exposure by minimizing unrestrained explosion of transient cavities. This is accomplished through the study on Sonoluninescence (SL), the phenomenon of release of light when liquid is irradiated by sound wafers of sufficient intensity, as a sensitive indicator of cavitation events [2, 3]. This paper compares the effects of CO2 dissolution on particle removal efficiency (PRE) and pattern collapse in a range of megasonic power with >100nm-size Si3N4 particles and 2xnm node line/space-pattern, respectively to N2-gasified water (N2 DIW).

Experimental

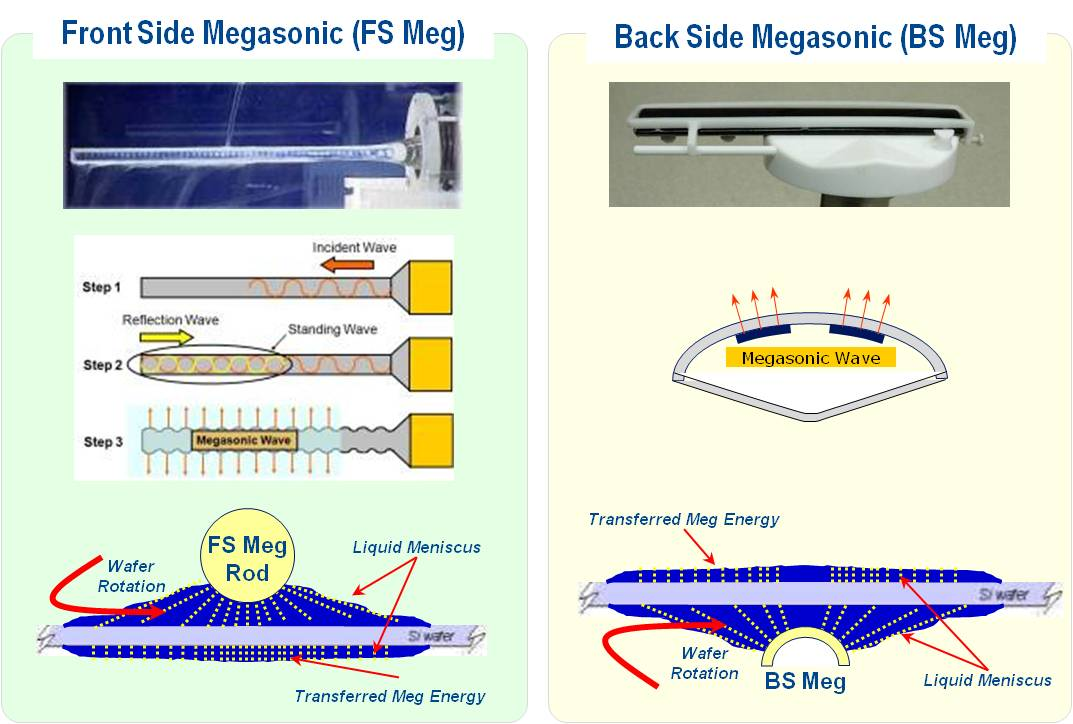

Experiments were performed on a 300mm Akrion Systems’ Goldfinger® Velocity™ tool, which provides two different types of megasonic cleans; Front Side (FS) megasonic systems with a quartz rod connected to piezoelectric crystal (1.6MHz) and Back Side (BS) with a plastic-covered piezoelectric material (830kHz), as shown in Figure 1. CO2 (approx. 1000ppm) DIW and N2 (approx. 20ppm) DIW were prepared using each membrane continuously filled with CO2 or N2 at a certain pressure. For the particle removal experiments, 300mm bare silicon wafers were contaminated with Si3N4 particles (>100nm in diameter and around 20,000 particles per wafer). Number of particles on the wafer was counted from 100nm-size by SP1 (KLA-Tencor) before/after contamination and after cleans. Pattern collapse evaluations were conducted on two different kinds of multi-stacked gate poly structures; 25nm-width with 9:1 aspect ratio (AR) and 35nm-width with 10:1 AR.

Results and Discussion

PRE for Si3N4 particles was compared between CO2 DIW (RT) and N2 DIW (RT) in 0~50W range of FS and BS Meg power as shown in Figure 2. Goldfinger® BS Meg can remove particles from both the front and back sides at the same time with sufficiently high PRE as FS Meg does for front side only. CO2 DIW showed >50% lower PRE than N2 DIW that would be related to the ability of CO2 to quench SL generation in DIW exposed to megasonic radiation [3]. Acidity of CO2 DIW would be one of the reasons for lower PRE of CO2 DIW; however, spiking diluted ammonia water (1:800 =30% NH4OH:DIW) to the CO2 DIW (no change on CO2 concentration) puddle on the wafer surface during megasonic radiation provides comparable PRE to N2 DIW.

Fig1

Pattern collapse was compared between CO2 DIW and N2 DIW with 25nm-width (AR=9:1) gate poly wafers in 0~50W range of FS or BS power. As shown in Error! Reference source not found., pattern collapse was greatly improved by CO2 dissolution with zero collapse at 30W Meg power, which has >40% PRE. Wafer damage was evaluated again on a 34nm-width (AR=10:1) gate poly pattern in order to see any loss by pattern collapse when using diluted NH4OH spikes to improve the PRE of CO2 DIW. According to Table 1, wafer damage was not found even at 40W BS Meg power at which >85% Si3N4 particles are removed from the silicon surface. The results indicate that CO2 suppresses pattern collapse in DIW, and is also able to inhibit wafer damage in the presence of other gases that may cause pattern collapse.

上一篇: 等离子体中硅刻蚀的机理