1. INTRODUCTION

Contamination of projection optics in EUV exposure tool is a critical issue and has to be addressed where EUV lithography is to be employed in high volume manufacturing. The reflectivity of the imaging mirrors decreases because of deposition of carbonaceous film and/or surface oxidation. EUV mask has the same issue but in that case its lifetime requirement is less stringent compared to projection optics. The influence of carbon deposition on a multilayer surface depends on the film characteristics. At the EUV wavelength, optical properties depend strongly on the density of the films rather than on the chemical bonding structure. Although the deposition mechanisms have been widely studied, the density of the carbon films deposited by EUV exposure in vacuum and its dependence on the conditions are not well understood. In this work, the impact of carbon deposition characteristics on lithography performance and the cleaning of deposited carbon film are studied.

As for the cleaning of the carbon contamination, two kinds of cleaning process have been reported. One uses oxidative and the other uses reductive reactions. Oxidative process uses the oxygen containing active species generated by the excitation source such as ultraviolet light. Although the oxidative reactions remove the carbon contamination from the surface, oxidation of the capping layer surface causes reflectivity change. Cleaning process using atomic hydrogen is one of the solutions to remove the contaminants without the surface oxidation [1]. Using this process, removal of the carbon contamination on multilayer mirror surface has been demonstrated. In this study, this technique was applied to EUV mask cleaning.

2. CHARACTERIZATION OF CARBON FILM

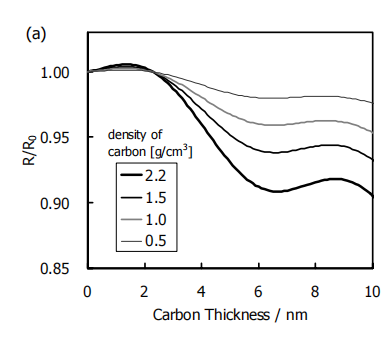

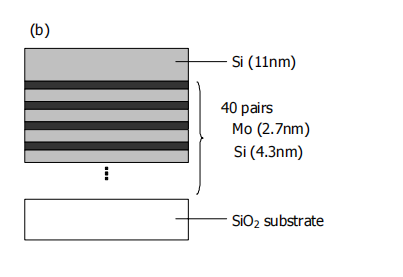

Fig.1 (a) shows the decrease in reflectivity due to carbon deposition on an EUV mask surface. The reflectivity change is dependent on the density of deposited carbon film. They are calculated by assuming the multilayer structure shown in Fig.1 (b). Optical constants 1 G iE of each layer materials can be obtained using equation (1), where r0 is the classical electron radius, O is the wavelength, nq is the number of atoms of type q per unit volume, and 0 f q is the complex atomic scattering factor for atom q [2]. The atomic scattering factor of each element is obtained from the www site of Lawrence Berkeley Laboratory [3] and the density of multilayer is assumed to be the same as that of the bulk material.

Fig1

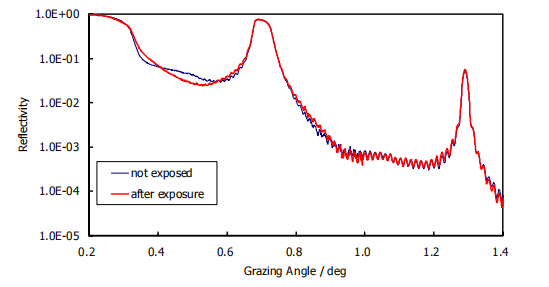

In order to investigate the carbon film characteristics, intentionally contaminated multilayer samples were prepared using synchrotron radiation. Si-capped multilayers (40 pairs of Mo/Si) on 6025 quartz glass substrates were used as substrates. The multilayer sample was exposed to synchrotron radiation at beamline SBL-1 of the Super-ALIS storage ring at NTT. The exposed area at the sample surface was about 25 mmu 5 mm. The wavelength of the beam was in the range of 1 nm to 20 nm. The pressure in the sample chamber during the irradiation ranged from 1u 10 4 to 4u 10 6 Pa. The partial pressure of hydrocarbon was determined to be ~0.1% by the residual gas analyzer. The EUV peak reflectivity of the multilayer decreased by about 2.5% after receiving an exposure dose of ~30000 A s which corresponds to 5~10 J/mm2 . Fig. 2 shows the result of grazing incidence X-ray reflectivity measurement of the sample after the exposure. The reflectivity of the exposed area showed slight changes as the grazing angle was varied from 0.3 to 0.7 degree.

Fig2

3. IMPACT ON THE PRINTING PERFORMANCE

The impact of carbon contamination of mask on the lithography performance was investigated by using SOLID-EUV, an electromagnetic field simulator from Synopsys. The calculations were carried out using the waveguide method because the calculation speed is much higher than that of the FDTD algorithm. Linewidth variations of 32 nm dense, semi-dense and isolated lines by carbon deposition on the mask were simulated. The linewidth was determined from the aerial image intensity profile and a given threshold. Numerical aperture and partial coherence of the projection optics was assumed to be 0.25 and 0.7, respectively. Aberration and flare of the optics were not taken into account. Incident angle to the mask was 6 degree. The EUV mask model was simplified as Ta absorber (70 nm)/Si capping layer (11nm)/40 pairs of Mo (3nm) - Si (4nm) multilayer. Optical constants were obtained by assuming that the density of each layer were the same as that of the bulk material. Considering the result shown in the previous chapter, the density of the carbon contamination layer was assumed to be 1.2 g/cm3 . The line patterns of both parallel and perpendicular to incident plane were simulated and compared with each other.

下一篇: InGaAsP晶圆的化学蚀刻