Target workplace

We conducted an evaluation of one of the production lines where leukemia had occurred, which was established in 1988 and used the oldest method of production. The production line under survey was a large-scale clean room building 100 mL × 50 mW, with a multi-level structure divided into 1st and 2nd floors, divided into about 25 bays, or work spaces. Generally the production process consisted of six steps (diffusion, lithography, etching, ion implantation, chemical vapor deposition (CVD), and metallization) and each step consisted of 3-6 bays depending on the type of process. Measurements were carried out at 9 bays representing the main stage of the process. Each bay was about 3 mL × 20 mW, and evaluations of exposure levels were conducted by dividing each bay into 3 areas. Thus, monitoring was conducted in 27 different measurement locations. To verify the daily exposure variations, duplicate measurements were performed on two separate days.

Accordingly, Bays 3 (wet etching), 6 (dry etching), 9 (lithography), 13 (ion implantation), and 14 (chemical vapor deposition) on the 1st floor, as well as bays EF 2, 14 (lithography), EF16 (dry etching), and EF 17 (chemical vapor deposition) on the 2nd floor were selected for the evaluation. Diffusion and metallization processes were not investigated, because they do not use target chemical substances for this research project.

The first work for the investigation took place in May 2007 to verify on-site processes and handled chemical substances. The second preparatory investigation was conducted in June 2007 to set up a detailed investigation plan. On-site exposure monitoring was carried out in September 2007.

Measured chemical substances

We monitored chemical substances categorized as human carcinogens with respect to leukemia, harmful chemicals currently regulated by the Korea Ministry of Labor (KMOL) that were used in the bays, and substances with hematologic and reproductive toxicities to evaluate the overall health effect for semiconductor workers (Appendix 1). Among the regulated harmful substances, the study measured acids (sulfuric, hydrofluoric, hydrochloric, nitric, phosphoric), organic solvents (isopropyl alcohol, toluene, xylene, etc.), phosphine, 2-heptanone, ethylene glycol, as well as known human lymphohematogenic carcinogens, such as benzene, chemicals with hematologic toxicity, such as arsine, and substances with reproductive toxicity, such as fluoride, n-butyl acetate, cellosolves, and propylene glycol mono methyl ether acetate. Exposure criteria for the chemical substances that were measured are shown in (Appendix 2). Carcinogenic categories recommended by the ACGIH include sulfuric acid (A2), fluoride (A4), hydrochloric acid (A4), and isopropyl alcohol (A4), while the US-EPA (US Environmental Protection Agency) has insufficient data to show that phosphine is carcinogenic in humans according to its category EPAD (not classified as to human carcinogen) and is therefore a substance difficult to classify. Arsine is a potential carcinogenic substance according to the National Institute for Occupational Safety and Health (NIOSH) classification NIOSH-Ca (Potential Occupational Carcinogen). According to the International Agency for Research on Cancers standard, benzene and sulfuric acids are classified as group 1 carcinogens.

Measurement method

The workers have to wear a bunny suit (clean suit), a kind of body suit, which made it difficult for them to wear the personal air-sampling device, so area samples were mainly collected for this study. However, at bays where organic solvents were measured, in addition to area sample collection, a personal passivetype sample-collecting device (3M 3520 organic vapor monitor) was used along with the area samples. As the Bay 3 wet etching process is the oldest process in the factory where workers manually put silicon wafers directly in a plating bath and withdraw them, simultaneous 15-min short-term exposure concentration (STEL) measurements were conducted with 8-hr long-term samplings.

Fig1

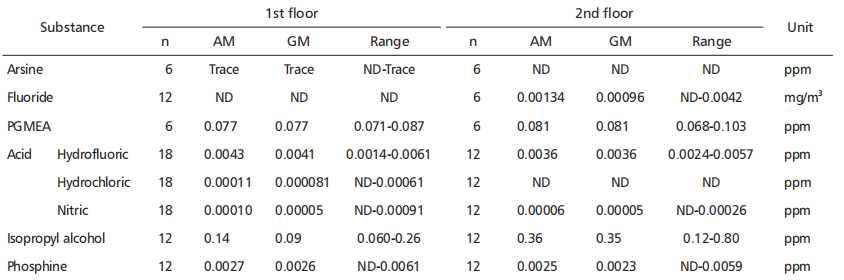

Sulfuric and phosphoric acid were “ND” in all samples. Hydrochloric acid was “ND” in 2 of 30 samples, and nitric acid was “ND” in all but 5 samples. Hydrofluoric acid had the highest concentrations among all the acids and this was detected in all samples, but its highest concentration was 0.0061 ppm, or about 0.2% of the KOEL. However, according to the 15-min. short-term exposure concentration evaluations at Bay 3, the maximum concentration of hydrofluoric acid was detected at 0.102 ppm, amounting to 3.4% of the KOEL and roughly 5.1% of the ACGIH standard.

The arithmetic and geometric means of isopropyl alcohol were 0.25 ppm and 0.19 ppm, respectively. The concentration range was 0.059-0.80 ppm and this was about 0.03-0.4% of the KOEL. Phosphine exhibited a range of “ND” - 0.0061 ppm and only 4 samples had detectable levels among the total of 24 samples. The highest exposure of 0.0061 ppm was about 2% of the KOEL.

上一篇: 磷酸中二氧化硅的选择性湿法蚀刻方法

下一篇: 氢氧化钠溶液中氢对铁的阳极氧化