Abstract.

Aluminum nitride is wide and direct band gap compound semiconductor material. High temperature strength, good thermal conductivity, small thermal expansion coefficient, strong corrosion resistance, good dielectric properties and other characteristics make aluminum nitride as impact resistance material, crucible materials, and conductive materials widely applied in various fields. This paper reviews the production method of aluminum nitride powder and its application in different fields.

Introduction

Aluminum nitride is a ceramic insulator, a third-generation semiconductor material. Aluminum nitride in the band gap at room temperature is 6.42eV, thermal expansion coefficient of 4.5 × 10-6°C; the maximum stable to 2200 °C [1-4].This paper describes the basic characteristics of aluminum nitride based on aluminum nitride powder production method and its application in various fields.

Basic Structure and Properties of Aluminum Nitride

Comparisons of aluminum nitride and other materials are shown in Table 1. Compared with other materials, it can be seen that the melting point of aluminum nitride is higher, the coefficient of thermal conductivity is larger and the band gap is wider. These characteristics are caused by the internal structure of the special aluminum nitride.

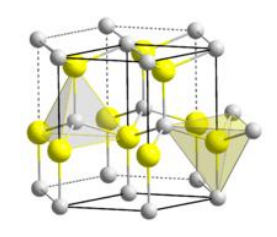

Aluminum nitride is connected by covalent bonds. Fig. 1 shows the crystal structure of aluminum nitride. It has a hexagonal crystal structure, which is the same as zinc sulfide and zinc sulfide ore. Aluminum nitride space group is P63mc [5]. Its spatial structure led aluminum nitride has a high thermal stability, so that it should take before pressing and welding to produce industrial-grade material.

Band-gap at room temperature of aluminum nitride is 6.42eV, which belongs to direct band-gap semiconductor [6].The minimum value of its valence band and the maximum of its conduction band are located on the origin of the K space, when the electron from the valence band to the conduction band, only need to change the energy on, without changing the electron quasi-momentum, which leads to the efficient transport of electrons, making aluminum nitride for light-emitting devices or other optoelectronic devices.

Preparation Method of Aluminum Nitride

Since aluminum nitride has good physical and chemical properties, it has been widely favored by science, but because of its higher processing costs, method of manufacturing aluminum nitride will also continue to develop.

Electrical Explosion Method.

Electrical explosion method is able to extract high-purity aluminum nitride methods emerged in recent years [10].Studies have shown that, under 34KV power supply voltage and capacitance of 1.6μF storage conditions, high purity nitrogen as working gas, the pressure in the product range of 0.25 ~ 1.50Mpa prepared for nano-aluminum nitride and nano-aluminum mixtures.

Application of Aluminum Nitride

Aluminum nitride has a wide band-gap width, the stable crystal structure, good dielectric characteristics and the like so that it has been widely used.High purity aluminum nitride powder is the main raw material to manufacture high thermal conductivity of the aluminum nitride ceramic substrate.

The aluminum nitride ceramic substrate, high thermal conductivity, low coefficient of expansion, high strength, high temperature, chemical resistance, high resistivity, low dielectric loss, is the ideal LSI heat dissipation board and packaging materials[11].Aluminum nitride has high hardness characteristics, is the new wear-resistant ceramic material that can be used badly worn parts [12].The use of aluminum nitride ceramic heat melt erosion resistance and thermal shock resistance can be made GaAs crystal crucible, aluminum evaporating dish, MHD power generation equipment corrosion and high temperature turbine components [13].Use of its optical properties can be used for infrared window. Aluminum nitride film can be made high-frequency piezoelectric elements, VLSI substrate or the like.Aluminum nitride is non-toxic, better performance of its metalized ceramic can replace toxic oxidation-sensitive porcelain is widely used in the electronics industry.

Fig1

In the preparation of high purity alumina. Due to the manufacturing process constraints, difficult to synthesize short growth cycle, high-precision, low-cost, large-scale aluminum nitride powder. This makes the price of aluminum nitride bottleneck expensive, even in its application to study more, but limits the processing of large-scale use of aluminum nitride. Synthesis of superior quality silicon nitride will be a trend of the future direction of technology development.

The oxidation of aluminum nitride.Exposed to the air increases the oxygen content of aluminum nitride, it is necessary when producing aluminum nitride powder and then its surface modification.

We need to seize the pulse of the times, through scientific and technological progress and constantly improve the processing technology of aluminum nitride, aluminum nitride expand the application level.

上一篇: 氢氧化钠溶液中氢对铁的阳极氧化

下一篇: 生长宽带隙半导体氮化铝晶体的环保方法