I. INTRODUCTION

Phosphorescent organic light emitting diodes (OLEDs) have drawn considerable attention because of their ability to harvest both singlet and triplet excitons simultaneously through intersystem crossing, approaching a near 100% internal quantum efficiency.1 Mostly, highly efficient phosphorescent OLEDs have been fabricated through high vacuum thermal evaporation by following multilayer device architecture.2-3 The additional layers like charge-transport and carrier-blocking can help balance charge injection to the emissive layer and enhance device efficiency. To make cost-effective and large-area rollto-roll fabrication, wet-processable phosphorescent OLEDs with higher efficiencies are in extreme demand.4-5

In this work, high efficiency green phosphorescent OLED was fabricated by using spin-coating to deposit hole-injection layer, poly(ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS) and emissive layer. The resultant OLED device exhibited a power efficiency of 46 lm/W and current efficiency of 58 cd/A at 100 cd/m2 . Further, 4,4,4-tris(N-carbazolyl)- triphenylamine (TCTA) and N,N-dicarbazolyl-3,5-benzene (mCP) layer were deposited onto hole-injection layer PEDOT:PSS through spin-coating in the individual devices. The resultant devices showed significant performance improvement.

II. EXPERIMENTAL

A. Device Fabrication

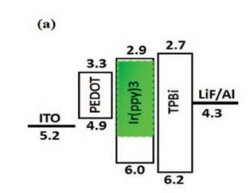

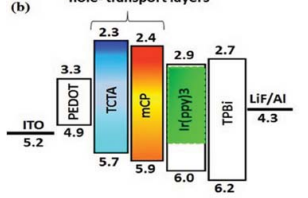

The schematic energy-level diagrams of OLEDs are shown in Figure 1. All the devices were fabricated on pre-cleaned glass substrate coated with a 125 nm indium tin oxide (ITO) layer. The fabrication process included first spin-coating an aqueous solution of PEDOT:PSS at 4000 rpm for 20 s on ITO anode layer. The resulting hole-injection layer was baked at 150 °C for 40 mins. The emissive layer consisted of a host 4,4,NN-dicarbazolebiphenyl (CBP) doped with green dye tris(2phenyl-pyridine) iridium (Ir(ppy)3). The emissive layer solution was prepared in tetrahydrofuran at temperature of 40 °C for 0.5 h with stirring. The resulting solution was then spincoated at 2500 rpm for 20s under nitrogen. Thereafter, the electron-transporting layer TPBi, the electron injection layer LiF, and the cathode Al, were deposited by thermal evaporation in a vacuum chamber at the base pressure of 10-4 Torr (Device A). For Device B and C, an additional holetransport layer of TCTA and mCP spin coated at 2500 rpm for 20s onto PEDOT:PSS, respectively. The resulting holetransport layers of TCTA and mCP were baked at temperature 60 °C and 50 °C for 30 mins, respectively to remove residual solvent before the deposition of the emissive layer.

B. Device Characterization

All the resultant devices were measured under atmospheric condition. The current density-voltage and luminance (J-V-L) characteristics of the resultant devices were measured through a Keithley2400 electrometer with Minolta CS-100A luminance-meter, while the spectrum and CIE color chromatic coordinates were measured by using PR-655spectrascan spectroradiometer.

Fig1

III. RESULTS AND DISCUSSION

Table 1 compares the performance of the wet-processed green phosphorescent OLEDs without (Device A) and with an additional hole-transport layer (Devices B and C). Initially, Device A exhibited a power efficiency of 46 lm/W, and a current efficiency of 58 cd/A, and an external quantum efficiency of 15.7% at 100 cd/m2 . The employment of the small molecule host material, CBP, could satisfy the requirements for high efficiency phosphorescent OLED. First, the triplet energy of CBP (2.55 eV) is higher than that of green emitter, Ir(ppy)3, which is 2.4 eV, avoiding the quenching of triplet exciton of the emitter by the host. Subsequently, host CBP makes an efficient energy transfer route from host to the triplet emitter, resulting in a high power efficiency. Secondly, CBP has bipolar charge-transport characteristics.13 To achieve a high recombination rate in the desired emitting layer, a balanced carrier-injection to the emissive layer is hence necessary. The inherent bipolar characteristic of CBP balanced the hole- and electron-transport to the emissive layer, improving recombination rate and also decrease the efficiency roll-off. Thirdly, a good solubility of host CBP and green emitter Ir(ppy)3 in the solvent, tetrahydrofuran, ensuring a smooth film thickness and also help prevent non-uniformity resulting from unwanted segregation of host or emitters materials.

上一篇: 简单湿化学法制备ZnO纳米结构

下一篇: 铝蚀刻剂研究