SCOPE AND PURPOSE

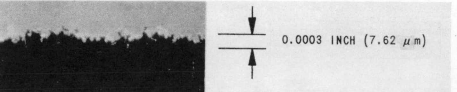

As many aluminum etchants as possible were evaluated for etchingprecision elements in 0.00045-inch-thick (11.43 um) type 1145 aluminum, When the elements etched in thepresent etchant are magnifiedto a sufficiently high level to measure their width precisely(100X to 300X), the edge roughness (peak to valley) of 0.0003 inch(7.62 um) becomes apparent.This uncertainty in the exact lo-cation of the element edge contributes to nonrepeatable widthDevelopment of an etchant capable of producingmeasurements.apeak-to-valleyedge roughness of less than 0.00005 inch (1.27umis the primarygoal of this development effort.

ACTIVITY

The precision pattern hardware under study at Bendixincludes several etched 1145 aluminum laminates.The laminates are composed of one layer of 0.00045-inch (11.43 um)aluminum,two layers of 0.005-inch (0.127 mm) Mylar,and onelayer of 0.004-inch (101.6 um) aluminum.Elements ranging from0.005 to 0.050 inch (0,127 to 1.27 mm) wide are etched throughthe thin aluminum to a required width variation of t0.000025 inch(+0,635 um). Less critical patterns are etched through thicker[0.004 inch (101.6 um)] aluminum.Photoresist is used to protectdesignated areas from the etchant and allow uncoated areas to etchaway.

Because an almost inexhaustible number of chemical solutionscapable of etching aluminum is available, no specific method hasbeen established to choose candidates for study. More than 80solutions which are mentioned in literature or are combinationsof chemicals known to attack aluminum have been tested.Theetchants investigated so far have ranged from extremely acidicto extremely alkaline. Evaluation of the etchants have beenprimarily concerned with etched edge smoothness.

Currently,an etchant containing five parts by volume 85-percent HgP04, five parts water, and one part Rapid Circuit Etch* is used his'solution produces a relatively ragged edge (Figure 1) which makes it difficult to repeatably measure element widths to better than t0.0002 inch (5.08 um). Only by averaging the peaks and valleys can this repeatability be achieved.

Fig1

Because an almost inexhaustible number of chemical solutionscapable of etching aluminum is available, no specific method hasbeen established to choose candidates for study. More than 80solutions which are mentioned in literature or are combinationsof chemicals known to attack aluminum have been tested. Theetchants investigated so far have ranged from extremely acidicto extremely alkaline, Evaluation of the etchants have beenprimarily concerned with etched edge smoothness.

上一篇: 高效湿处理磷光有机发光二极管

下一篇: 氮化镓的深紫外增强湿法化学蚀刻