ABSTRACT: Wet chemical processes are widely used within crystalline silicon solar cell production, mainly for surface texturing and cleaning purposes. Whereas research has been focusing mainly on process development in the past, only little progress could be observed in terms of process control techniques. Within the paper current state-ofthe-art wet chemical production processes are discussed and process control and quality assurance procedures (chemical, optical and electrical characterization of the wafers) are proposed. Purpose of the advanced characterization techniques is an enhancement of the process quality as well as an increase in high quality production yield. Further on, future industrial high efficiency cell processing necessitates cost effective, high quality cleaning processes especially prior to any surface passivation step. Starting from the well known semiconductor cleaning sequences, the paper motivates process simplifications and adaptations suitable for PV mass production. Keywords: wet chemistry, process control, characterization.

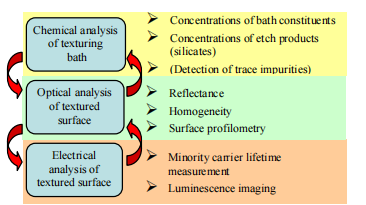

Quality assurance and process control for wetchemical applications are becoming increasingly important in the industrial production chain to manufacture silicon solar cells. To overcome process operations based on operator experience as well as to extend overall operating times of common etching bathes, new developments for online characterisation and control will be mandatory.

For the process development, new requirements emerge from transferring high efficiency cell processes from lab scale towards industrial production equipment. Especially higher standards for the wafer and surface cleaning at various stages within the cell process are required; nonetheless, production costs and therefore process complexity have to be kept as low as possible.

Fig1

Additionally, from a scientific point of view, a better understanding of the underlying mechanisms especially for the texturing processes could be achieved, which in the end again will support further process optimization. As an example for the importance of an elaborate process control, chemical consumption data for a typical acidic texturing process can be taken: Assuming an average industrial bath operating time of around 80h, the amount of dosed HF and HNO3 during that time period accumulates to a factor of 10 to 15 higher than the original amount of HF and HNO3 used for the fresh bath make-up. These figures demonstrate, that basically the overall process performance is mainly driven by an accurate dosing of the consumed chemicals and therefore their exact determination is of great importance.

In comparison, texture 3 shows lowest reflectances, but also low shunt resistances and hence low Voc. This can be attributed to an extremely rough surface structures with a lot of deep etch pits formed at crystal defects and grain boundaries. Subsequent SiNx deposition fails to homogeneously cover these deeply etched areas resulting in inhomogeneous contact formation and hence low shunt resistances and conversion efficiencies.

上一篇: 氢氟酸水溶液中离子辐照LiNbO3的蚀刻

下一篇: CMP后晶片表面金属污染物的清洗方法