RIDGE waveguides are important basic structures of integrated optics. In comparison with conventional guides, ridge waveguides can reduce bending losses improving in this way the integration level of optical devices. Moreover, ridge guides reduce the size of optical modes enhancing the effificiency of nonlinear effects [1]. In electrooptical materials such as lithium niobate (LiNbO , LN) ridges can also reduce the half-wave voltage or length of modulators .

Fig. 1 shows a comparison of the surfaces of undoped LN etched by HF–HNO without and with ethanol. Fig. 1(a) is a top view of the LN surface etched without ethanol. The etch depth is about 7.5 m. Fig. 1(b) is a side view of the sample surface, showing two types of hillocks, marked by and , respectively. The density of hillocks of type is much higher than that of type , and is affected by the intensity of stirring. Slow stirring generates a high density of hillocks. Fig. 1(c) is the LN surface etched by HF–HNO with ethanol; the etching depth is about 9.6 m. The surface is smoother than that shown in Fig. 1(a), but there are still some hillocks of type on the surface, which are shown in Fig. 1(d). It seems that during the etching process small bubbles of hydrogen can be generated, which are adsorbed on the surface and impede further chemical etching. The result is a rough surface. Ethanol helps to avoid the bubble formation, yielding a much better surface quality, as shown in Fig. 1(c). An analogous explanation was reported in reference for etching silicon.

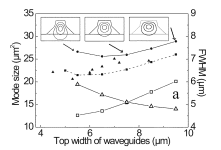

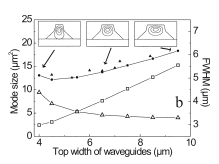

Fig5

The mode size is an important parameter in particular for nonlinear optics applications. It was calculated and measured for a number of Y-propagating ridge waveguides of different width; the results are shown in Fig. 5. The mode size defifined in this letter is the product of the FWHM of the mode intensity distribution in vertical and horizontal directions. The FWHM of the mode intensity in vertical direction is decreasing with increasing waveguide width, whereas the FWHM of the mode intensity in horizontal direction is increasing. Fig. 5(a) shows the TE mode size. It decreases as function of the waveguide width down to about 6.5 m, and increases at smaller widths when approaching cutoff. The calculated and measured TE mode sizes show a similar dependence but with an offset. This difference might be due to the inaccuracy of the theoretical model describing the ordinary refractive index with its nonlinear dependence on the Ti concentration. By assuming a higher refractive index increase (20% increase), the mode sizes are recalculated and shown in Fig. 5(a) as well resulting in a somewhat better agreement of measured and calculated results. Fig. 5(b) shows the calculated and measured TM mode sizes, which agree well.

Three main results have been reported as follows: 1) A flflat etched surface of pure LN is obtained by adding some amount of ethanol to the HF–HNO etchant. 2) A Cr fifilm can be used as mask in the wet etching process; appropriate annealing significantly reduces the underetching. 3) Monomode ridge waveguides of low propagation losses have been fabricated; as an example, they are 0.3 dB/cm for TE-, and 0.9 dB/cm for TM-polarization, respectively, in a guide of 6.5- m width and 8- m height at 1.55- m wavelength.

The authors would like to thank B. Gesemann for initial fifinite-element-method calculations of the mode distributions. They also thank Dr. H. Suche, Dr. S. L. Schweizer, and Dr. H. Herrmann for helpful discussions.

上一篇: 辅助陶瓷蚀刻的超声加工

下一篇: 薄膜氧化物半导体评估系统