In the damascene integration scheme, copper is used as an interconnect material. In a damascene integration scheme, the etch treatment by a plasma process leads to the formation of polymer residues, copper sputtered on the dielectric side wall, copper oxidation at the bottom of the via and copper precipitates at the hard mask surface. In order to remove these impurities, a post-via etch cleaning is mandatory .

Several aqueous cleaning solutions constituted of diluted HF and an organic acid were tested. Diluted HF was mainly used to remove the polymer residues and the organic acid to clean the copper surface. These mixtures were already studied and compatible with several porous and dense ULK materials . In this paper, the impact of organic acids and gas bubbling in diluted HF solution on copper and copper oxide-dissolution rate is presented. Firslty the copper oxide and the copper etch-rates and the roughness were obtained from the kinetics of copper dissolution determined by X-ray reflectometry characterization . Secondly, speciation calculations were performed in order to explain the copper etch-rates differences as a function of the solutions and gas bubbling.

200 mm samples were prepared by depositing a copper (PVD) layer of 500 Å on a TiN layer of 100-150 Å on a silicon substrate. The copper wafers were exposed to clean-room atmosphere in order to have a copper oxide film of several angstroms (35 to 40 Å). Several solutions (aqueousbased chemistry) containing an organic acid 3.5 w% or diluted HF 0.05 w% plus organic acid 3.5 w% (Table I) were tested. The gas content in the solution was tuned by O2 or N2 gas bubbling.

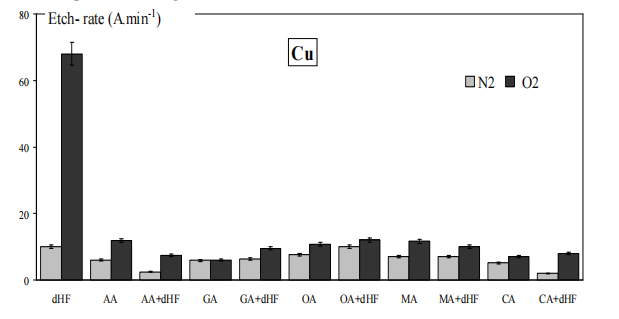

The copper oxide etch-rates in all the solutions tested are higher than 150 Å.min-1. The copper dissolution rates in organic acid and in dHF + organic acid solutions were calculated by the same method and are presented Figure 1.

Firstly the copper etch-rates in solutions of organic acid and dHF + organic acid are close and lower than 13 Å.min-1. Secondly, the impact of the gas bubbling is very important in dHF. Indeed the copper is seven times more etch in dHF under O2 bubbling than under N2 bubbling. On the contrary, the O2 bubbling in solution containing an organic acid leads to a very low increase of the copper etch-rate (close to uncertainties).

Fig1

The mixture of diluted HF and an organic acid is a low cost (simple) and ESH (diluted) cleaning solution. The addition of an organic acid in diluted HF solution have allowed a better control of the copper dissolution rate whatever the oxygen content in solution. This can lead to avoid the use of N2 bubbling in the different process: bath, spray and jet.

上一篇: 硅晶片兆声清洗过程中的去除力分析

下一篇: 氧化 HF 溶液中硅的金属辅助化学蚀刻